Role of air barriers in mitigating disease transmission

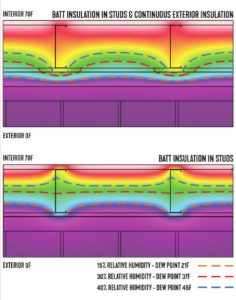

The upper image in Figure 14 illustrates a thermal model of a wall assembly that includes batt insulation in the stud cavity. The lower image includes both batt insulation in the stud cavity and exterior insulation in the air cavity. This is sometimes referred to as a split insulation method. The dashed lines represent the temperature within the wall at various corresponding dewpoint temperatures. If this wall assembly does not include effective air and vapor control at the interior, condensation could potentially form on surfaces within the stud cavity at elevated interior RH levels.

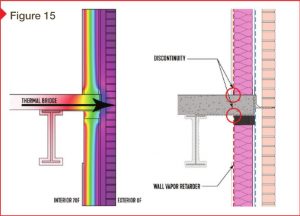

Like the roofing system, if the design includes an interior vapor retarder, it should be determined as to whether this component is also meant to provide air control. When utilizing interior vapor retarders that are also intended to provide air control, challenges can occur when detailing at penetrations and transitions to adjacent exterior enclosure assemblies, as demonstrated in Figures 15 and 16. This configuration also creates a thermal bridge at the floor line that can be a potential source of condensation when exposed to elevated levels of interior humidity.

Conclusion

In conclusion, the recently updated ASHRAE PD guidelines indicate the benefit of increasing the interior RH to a minimum of 40 percent to assist with infection control by reducing aerosol transmission. However, existing building performance can vary greatly when it comes to air leakage, thermal efficiency, and condensation resistance, and may not be able to accommodate this level of humidity in certain seasons. The enclosure performance can also be impacted by the type of building pressurization, both positive and negative. Evaluating and assessing the existing enclosure’s performance and condition is an important first step to avoid potential issues with increasing the RH.

Several forensic techniques can be employed to evaluate the existing construction in advance of altering the interior RH, including the removal of select materials (Figures 10 to 13), thermal modeling, diagnostic moisture testing, as well as infrared thermography. As highlighted above, verifying the presence and/or integrity of an air barrier system is also a priority. The forensic results can then be used to determine when, if, and for how long RH can be increased while limiting the risk for condensation.*

* The authors would like to credit Ryan Asava, AIA, NCARB, for the figures and the thermal modeling/analysis that informed the development of the figures. Asava is an associate at SmithGroup and a member of its Building Technology Studio. His primary focus is in the analysis of new and existing building enclosures. His project responsibilities include product research, energy code analysis, thermal calculations, and hygrothermal analysis. He can be contacted at ryan.asava@smithgroup.com.

Sarah K. Flock, CDT, AIA, is an associate principal at Raths, Raths, and Johnson (RRJ). She has more than 18 years of architectural experience in water/moisture intrusion investigations, repair design, and field testing of distressed structures, nonperforming buildings, and material systems. Specializing in building enclosure assessment, Flock has performed hygrothermal modeling to analyze a wide range of projects involving various types of building materials and systems. Her experience has involved peer review of building enclosures and assemblies to ensure the designs meet codes and standards for energy efficiency and environmental performance. Flock is the co-chair of the research committee, co-vice chair of the executive committee, and on the board of directors for the Air Barrier Association of America (ABAA). She can be contacted at skflock@rrj.com.

Sarah K. Flock, CDT, AIA, is an associate principal at Raths, Raths, and Johnson (RRJ). She has more than 18 years of architectural experience in water/moisture intrusion investigations, repair design, and field testing of distressed structures, nonperforming buildings, and material systems. Specializing in building enclosure assessment, Flock has performed hygrothermal modeling to analyze a wide range of projects involving various types of building materials and systems. Her experience has involved peer review of building enclosures and assemblies to ensure the designs meet codes and standards for energy efficiency and environmental performance. Flock is the co-chair of the research committee, co-vice chair of the executive committee, and on the board of directors for the Air Barrier Association of America (ABAA). She can be contacted at skflock@rrj.com.

Andrew Dunlap, AIA, CDT, LEED AP, NCARB, is leader of the building technology studio at SmithGroup. His primary work experience is in the analysis and development of exterior building enclosures including roofing, skylights, windows, curtain walls, rainscreen/cavity walls, and waterproofing. Dunlap regularly participates in reviewing and validating existing and new building enclosures for airtightness, thermal performance, energy efficiency, and condensation resistance. Dunlap is the co-chair of the Air Barrier Association of America (ABAA) research committee, co-vice chair of the executive committee, and is a member of the board. He can be reached via e-mail at andrew.dunlap@smithgroup.com.

Andrew Dunlap, AIA, CDT, LEED AP, NCARB, is leader of the building technology studio at SmithGroup. His primary work experience is in the analysis and development of exterior building enclosures including roofing, skylights, windows, curtain walls, rainscreen/cavity walls, and waterproofing. Dunlap regularly participates in reviewing and validating existing and new building enclosures for airtightness, thermal performance, energy efficiency, and condensation resistance. Dunlap is the co-chair of the Air Barrier Association of America (ABAA) research committee, co-vice chair of the executive committee, and is a member of the board. He can be reached via e-mail at andrew.dunlap@smithgroup.com.