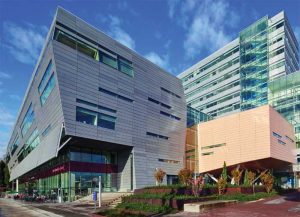

Role of WRB in open-joint cladding design

by Peter Barrett

Open-joint cladding enhances the visual appeal of buildings. However, it exposes the exterior wall to wind, water, and ultraviolet (UV) rays, thereby risking havoc to building performance and causing the growth of mold and rot within the wall cavity. Applying the right barrier in the appropriate place can help building professionals protect their designs well into the future and improve the overall performance as well as the appearance of a structure.

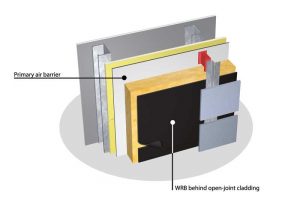

Water-resistive barriers (WRBs), specifically meant for open-joint cladding designs, are intended to be installed in front of the continuous insulation (ci) and behind the cladding itself. At this location, it does not replace the primary air barrier/WRB—these membranes are located in front of the structural sheathing and behind the ci (Figure 1).

Insulation protection

The primary role of a WRB designed for open-joint cladding systems is to channel bulk water from wind-driven rain (and snow) to the outside of the structure in order to keep it dry and maintain the insulation system’s performance. In effect, the WRB functions as part of the primary cladding. It will also protect the insulation from the R-value-lowering effects of wind-washing, a phenomenon occurring when air blows through a permeable insulation, disturbing the otherwise inert gases that give the insulation thermal value. Wind-washing refers to wind-driven flow of cold outdoor air through low-density insulation or air gaps in exterior continuous insulation (ci). This phenomenon can cool the interior side of the enclosure, thereby resulting in condensation.

Some experts believe this bulk movement of air can increase heat loss and cause condensation as well as greater energy consumption. However, several contributing factors can alter the severity of these effects, including insulation type, product thickness, and building height. So, while there is still some discussion in the industry regarding the overall effects of wind-washing on insulation, the fact is, the membrane behind the cladding protects the insulation from elements like wind when installed correctly.

Proper installation

To ensure the effectiveness of the WRB in an open-joint cladding system, it is essential to install the membrane and its components in a manner that seals all potential leakage points, including:

- connections of the walls to the roof’s air barrier and the building foundation;

- seismic and expansion joints;

- piping, conduit, duct, screws, bolts, and similar penetrations;

- changes in plane; and

- all other potential pathways for air and water leakage in the building enclosure.

Along with being water resistive, the right membrane should also be highly vapor permeable, allowing moisture within the cavity to escape swiftly through diffusion, while protecting the insulation from possible damage by moisture infiltration. Regardless of the type of membrane used, it is critical the moisture throttle should not be at this location as all interior moisture needs to move freely to the exterior.