Photo courtesy Allegrone Masonry

Dedication of the restored entry portals was scheduled for November 21. The stone-cutters and carvers worked feverishly to complete the work and make deliveries to the site. The masons onsite worked their magic with setting the stones. The backup was so irregular they chopped and filled to make everything fit. The final three elements—the finials—were delivered on November 17, just one week before the ceremony. A red carpet was laid and temporary handrails installed for the bishop’s arrival.

Meanwhile, the wheels fell off the oxcart for granite supply. The supplier in India could not replicate the tooling required on the treads and risers. Numerous samples and photos where sent back and forth via e-mail. Delay upon delay occurred, and the deadline of August 16 passed. It was not until the beginning of November the first delivery of granite arrived in North America.

Serious dimensional errors were discovered during the quality control phase. Some of the complex shapes had to be re-cut or corrected. Finishes were not complete, stones did not align, and units were off-square. It was too late to do a partial installation for the cathedral re-dedication, so the installation was deferred to the following spring. Cooler heads prevailed in the summer of 2011 and the installation was complete. All agreed although the project was delayed, the result was worth waiting for. The entry portals are a once-in-a-lifetime exhibition of the craft of masonry.

Conclusion

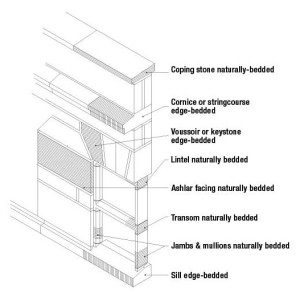

Red and brown sandstones are particularly difficult to match on North American restoration projects. Many quarries have closed over the centuries and environmental restrictions limit new extractions. Finding a reliable source of matching sandstone is more than just matching the color. Finding the material in large enough sizes and quantities before the project commences will save time and ultimately money for the property owner. Understanding bedding planes and proper installation techniques will help to avoid catastrophic failures. Sandstone is a material that requires significant lead-time.

The lessons learned during this project are twofold. The first relates to the original construction and the temptation of using an inferior material to save a few dollars. In the long run, the original savings of $40,000 cost the cathedral millions of dollars as the Connecticut brownstone is replaced. The recent decision to save $80,000 in the granite selection ultimately impacted the schedule and caused many sleepless nights. The quality, however, was never compromised.

The second lesson is one of patience and perseverance. Were it not for the mutual respect between the owner, architect, masonry contractor, and stone fabricators working together, the job would not have been completed to the high standards demanded by all.

Laurie Wells, BES (Arch.), MA, RSW, is a 20-year veteran of historic building preservation as an estimator and project manager. Her expertise spans pre-construction consulting, specification writing, budget preparation, and phasing of projects, along with trade coordination and project completion. Wells’ current role at Old World Stone Ltd., uses this knowledge to liaise between the building, its owners and design professionals, and the stone-fabricating cutters and carvers. She has lectured extensively to international architectural, technical, and historical audiences. Wells can be reached at laurie@oldworldstone.com.