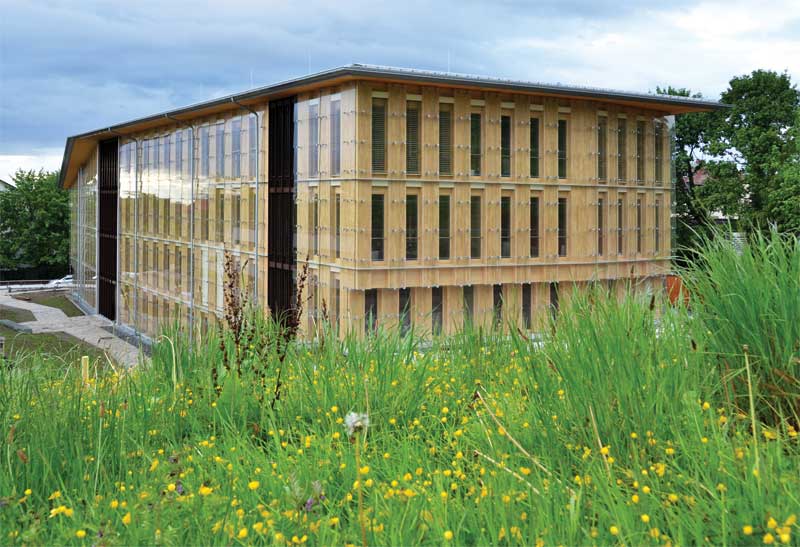

Photo © Längle

Contemporary methods of installation

For both new and existing buildings, installing ventilated glass systems and rainscreens is typically an efficient, non-obtrusive process, taking place on the structure’s exterior. External scaffolding and lifts can easily transport materials and workers up the façade, without affecting building operations. Occupants experience minimal disruption of their daily routines.

To speed installation, glass panels can be mechanically secured to the structural supports via quick, clip-in attachment fittings. These types of systems are able to insert each glass lite in less than 60 seconds, which can be advantageous for rushed project timelines. Lites are installed independently of each other, and a damaged unit can be replaced any time without deglazing adjacent panels.

High-performance, rigid insulation can be added behind the glass cladding through insulated metal panel (IMP) systems, which offer advanced energy conservation capabilities, combined with attractive surface finishes to complement the glass. They can achieve R-values of up to 8.25 per inch, and are available in thicknesses ranging from 50 to 152 mm (2 to 6 in.). IMPs’ clean surface finishes allow them to create a more visually pleasing cavity behind transparent and translucent glass types, maintaining pure design lines for back-lit applications.

Equipped with specialized structural rails, these IMPs are engineered to support the glass cladding’s weight. The integration of the multilayer rainscreen assembly (glass/air-and-water barrier [AWB]/thermal insulation) into a single multifunctional system provides clear installation advantages. It minimizes onsite labor and the need for multiple trades.

Photo courtesy Lahr Working Group

Testing requirements

Glass rainscreen systems should be rigorously tested in accordance with ASTM and American Architectural Manufacturer’s Association (AAMA) requirements for water penetration, pressure equalization, air leakage, and structural performance.

The applicable tests for rainscreen systems include ASTM E330-02, Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference, which is used for the structural performance of the glass cladding system. AAMA 509-09, Voluntary Test and Classification Method for Drained and Back Ventilated Rainscreen Wall Cladding Systems, tests whether systems are designed to manage and drain any water entering behind the cladding, and are also sufficiently vented to allow the cavity to dry. Tested rainscreen systems should prove they are able to stop at least 90 percent of the water that could potentially reach the building’s air and vapor barrier (AVB). The remaining 10 percent of water is gradually dissipated through drainage and evaporation.

Pressure equalization prevents moisture ingress and/or helps the drainage of any moisture finding its way behind the glass. Rainscreen systems tested under AAMA 508-07, Voluntary Test Method and Specification for Pressure Equalized Rainscreen Wall Cladding Systems, should prove they are able to stop 100 percent of the water, which could potentially reach the building’s AVB. These rainscreen systems are typically recommended for high-rise applications.

Additionally, National Fire Protection Association (NFPA) 268, Standard Test Method for Determining Ignitability of Exterior Wall Assemblies Using a Radiant Heat Energy Source, is used to determine if and how exterior wall assemblies may contribute to fire growth. Glass ventilated façades typically consist of noncombustible materials—an added benefit to buildings with strict fire codes.

| VENTILATED FACADES AND RAINSCREENS |

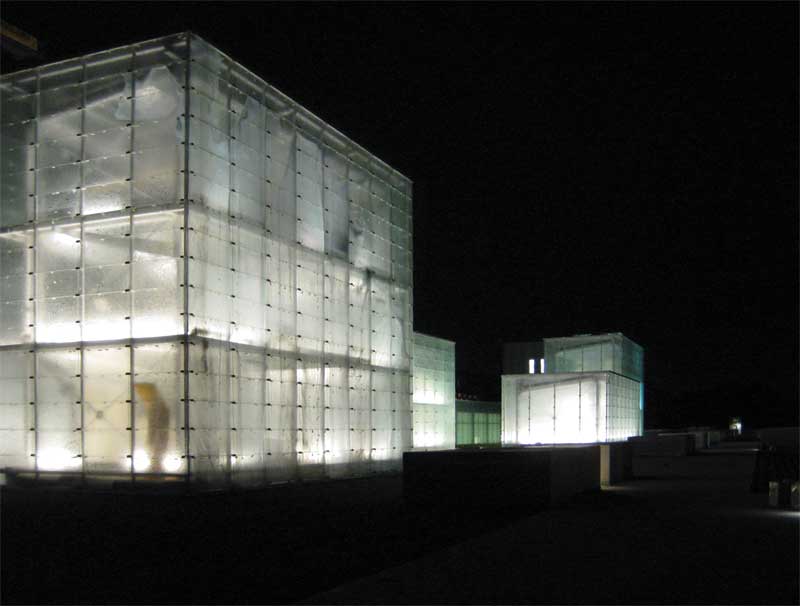

Photo courtesy Bendheim Glass rainscreen systems consist of multiple layered provisions for moisture control:

All rainscreens are ventilated façades, and, in most cases, the two terms can be used interchangeably. However, not all ventilated glass façades have to follow the three-layer structure of a rainscreen—cladding, cavity, and AVB. A ventilated glass façade may comprise the glass cladding layer alone, without another wall behind it. In this form, it is used to provide moisture protection for non-conditioned spaces (e.g. transit facilities, parking structures, pedestrian walkways, exterior stairways, and elevator towers). The external, ventilated glass cladding is mechanically fastened to a structural framework. It shields occupants from wind, rain, and snow, as well as offers a sense of openness, unobstructed daylight, increased safety, views, and ventilation. For more information on the benefits of glass rainscreens, visit |