See-through Rainscreens: Looking at the age of open, ventilated glass façades

by Katie Daniel | January 30, 2018 11:08 am

[1]

[1]by Said Elieh

Ancient construction relied exclusively on natural materials such as clay, wood, and stone. The industrial revolution introduced steel, which transformed the architectural world. Our era of rapid technological development is driving massive innovations in building materials and systems. These evolving solutions are designed for strength, ability to withstand adverse weather conditions, and never-before-seen aesthetic possibilities.

Contemporary ventilated glass façades and rainscreens[2] are perfect examples of such innovation. With its virtually unlimited design potential, glass has emerged as a modern cladding choice for these systems, which were previously dominated by opaque materials like wood, metal, stone, and terra cotta.

Glass is a highly valued material in architecture because of a unique blend of aesthetic and performance benefits. It is impervious to moisture, and enhances the building’s appearance and prestige. Transparent and translucent glass types maintain daylighting advantages like few other building materials.

In a properly designed ventilated façade, glass repels 90 to 100 percent of the wind-driven rain and moisture. It can comprise the entire façade for non-conditioned spaces—transit and parking facilities—or over-clad performance walls of conditioned spaces, as a typical multilayered rainscreen assembly.

The ethereal nature of glass allows design professionals to transform unexciting structures into striking, prominent buildings. It further enables the creation of kinetic architecture by completely changing its appearance from day to night.

The inherent qualities of glass evoke a range of positive associations—prestige, opulence, modernity, openness, brightness, and cleanliness. As a nonporous material, it can be a suitable choice for repelling water and wind. It is maintenance-friendly, and resists permanent staining and graffiti. Even if a building’s façade is constructed of wood, a properly designed glass rainscreen can protect it and ensure its performance for centuries.

Moisture protection

A growing number of design professionals are using ventilated glass façades for weather performance and aesthetic quality. Durable glazing provides ongoing protection against high winds and moisture, even in demanding coastal environments.

[3]

[3]Image courtesy Bendheim

Moisture is a notorious threat to old and new structures. With certain materials, it can deteriorate a building’s frame, exterior, and interior surfaces and lead to severe cases of mold, resulting in health hazards for building occupants. Holes, gaps, micro-cracks, and joints between materials and around openings can allow harmful moisture to enter the building. The threat and damage can be exponentially worse in freeze-thaw climates.

Water ingress is caused by a number of factors, including wind-driven rain, pressure differentials between the building’s exterior and interior, strong molecular attraction causing water to stick to the surfaces, and gravity. Well-designed ventilated glass claddings can be an effective envelope solution against water penetration. Their open joints allow air to circulate freely through as well as behind the cladding layer (Figure 1). The unrestricted airflow not only removes residual moisture behind the cladding through drainage and evaporation, but also prevents heat buildup behind the cladding layer.

History

The concept of over-cladding or double-skin façade design is not new. For centuries, Norwegian barn-style structures were built using layers of wood siding, set over a traditional stone or wood walls. These drained and back-ventilated claddings were installed with both closed and open joints. Many are still standing today.

Typical board and batten constructions have been used as ventilated façades in North America and elsewhere for more than a century. This type of design was often applied to wood-built structures like homes and barns.

Gradually, ventilated façades became adopted in commercial construction. According to building science professor John Straube (RDH Building Science Laboratories), the 30-story Alcoa Building in Pittsburgh, built in 1952, was an early example of a structure with a ‘pressure-moderated’ ventilated outer wall. It was a precursor of modern pressure-equalized rainscreen assembli[4]es[5].

During the 1960s and 1970s, a number of researchers studying rainwater penetration began discussing how to potentially reduce water and air leakage. They focused on ways to develop ‘two-stage weathertightness,’ with the outer (ventilated) wall acting as a rainscreen, and the inner (thermal performance) wall providing insulation.

By the 1980s, ventilated rainscreen façades became widely used in Europe and Canada for a wide range of building types. The U.S. commercial construction sector followed with rainscreens, featuring opaque cladding materials like metal, terra cotta, and fiber cement. Open-joint glass façade systems are now gaining recognition as a viable design solution among architectural professionals and building owners.

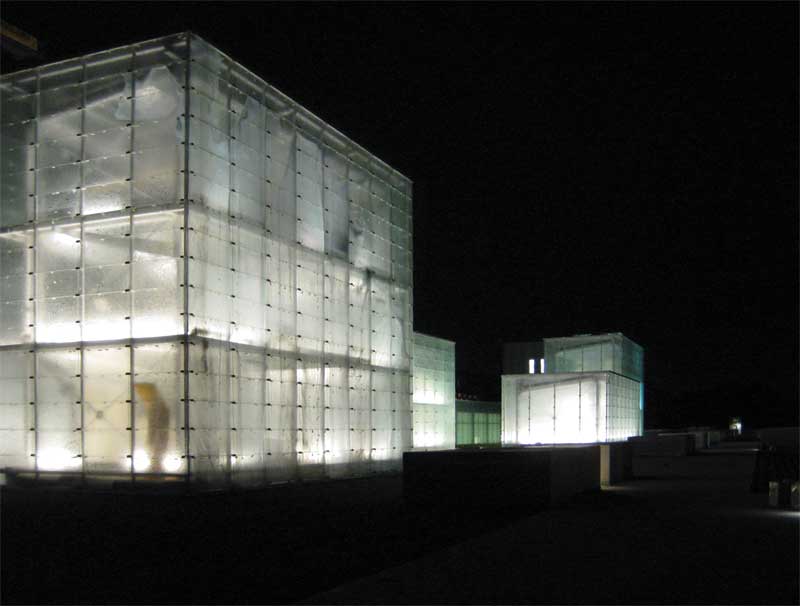

[6]

[6]Photo © Längle

Contemporary methods of installation

For both new and existing buildings, installing ventilated glass systems and rainscreens is typically an efficient, non-obtrusive process, taking place on the structure’s exterior. External scaffolding and lifts can easily transport materials and workers up the façade, without affecting building operations. Occupants experience minimal disruption of their daily routines.

To speed installation, glass panels can be mechanically secured to the structural supports via quick, clip-in attachment fittings. These types of systems are able to insert each glass lite in less than 60 seconds, which can be advantageous for rushed project timelines. Lites are installed independently of each other, and a damaged unit can be replaced any time without deglazing adjacent panels.

High-performance, rigid insulation can be added behind the glass cladding through insulated metal panel (IMP) systems, which offer advanced energy conservation capabilities, combined with attractive surface finishes to complement the glass. They can achieve R-values of up to 8.25 per inch, and are available in thicknesses ranging from 50 to 152 mm (2 to 6 in.). IMPs’ clean surface finishes allow them to create a more visually pleasing cavity behind transparent and translucent glass types, maintaining pure design lines for back-lit applications.

Equipped with specialized structural rails, these IMPs are engineered to support the glass cladding’s weight. The integration of the multilayer rainscreen assembly (glass/air-and-water barrier [AWB]/thermal insulation) into a single multifunctional system provides clear installation advantages. It minimizes onsite labor and the need for multiple trades.

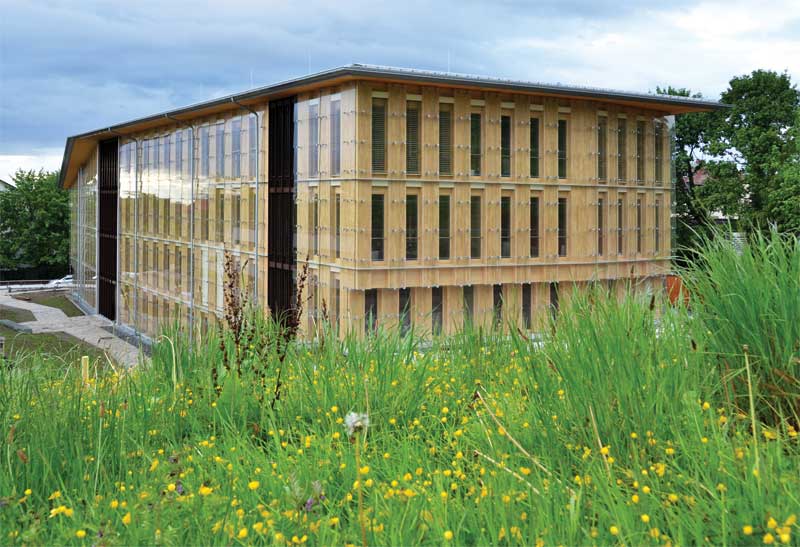

[7]

[7]Photo courtesy Lahr Working Group

Testing requirements

Glass rainscreen systems should be rigorously tested in accordance with ASTM and American Architectural Manufacturer’s Association (AAMA) requirements for water penetration, pressure equalization, air leakage, and structural performance.

The applicable tests for rainscreen systems include ASTM E330-02, Standard Test Method for Structural Performance of Exterior Windows, Doors, Skylights and Curtain Walls by Uniform Static Air Pressure Difference, which is used for the structural performance of the glass cladding system. AAMA 509-09, Voluntary Test and Classification Method for Drained and Back Ventilated Rainscreen Wall Cladding Systems, tests whether systems are designed to manage and drain any water entering behind the cladding, and are also sufficiently vented to allow the cavity to dry. Tested rainscreen systems should prove they are able to stop at least 90 percent of the water that could potentially reach the building’s air and vapor barrier (AVB). The remaining 10 percent of water is gradually dissipated through drainage and evaporation.

Pressure equalization prevents moisture ingress and/or helps the drainage of any moisture finding its way behind the glass. Rainscreen systems tested under AAMA 508-07, Voluntary Test Method and Specification for Pressure Equalized Rainscreen Wall Cladding Systems, should prove they are able to stop 100 percent of the water, which could potentially reach the building’s AVB. These rainscreen systems are typically recommended for high-rise applications.

Additionally, National Fire Protection Association (NFPA) 268, Standard Test Method for Determining Ignitability of Exterior Wall Assemblies Using a Radiant Heat Energy Source, is used to determine if and how exterior wall assemblies may contribute to fire growth. Glass ventilated façades typically consist of noncombustible materials—an added benefit to buildings with strict fire codes.

| VENTILATED FACADES AND RAINSCREENS |

[8] [8]Photo courtesy Bendheim Glass rainscreen systems consist of multiple layered provisions for moisture control:

All rainscreens are ventilated façades, and, in most cases, the two terms can be used interchangeably. However, not all ventilated glass façades have to follow the three-layer structure of a rainscreen—cladding, cavity, and AVB. A ventilated glass façade may comprise the glass cladding layer alone, without another wall behind it. In this form, it is used to provide moisture protection for non-conditioned spaces (e.g. transit facilities, parking structures, pedestrian walkways, exterior stairways, and elevator towers). The external, ventilated glass cladding is mechanically fastened to a structural framework. It shields occupants from wind, rain, and snow, as well as offers a sense of openness, unobstructed daylight, increased safety, views, and ventilation. For more information on the benefits of glass rainscreens, visit |

[10]

[10]Images courtesy Bendheim

Applications for glass façades

Double-skin glass façades are great design solutions for aging commercial properties. They can completely transform old buildings into modern, state-of-the-art structures with increased economic value.

Offices

In 2013, developers bought an unoccupied, unassuming, early ’80s building in San Jose, California, for an estimated $13.5 million. They contracted MODULUS Architects to design the building renovation. The renovation’s cost was approximately $4 million—10 percent of which was spent on a new glass rainscreen façade. The architects selected glass rainscreen for its durability and elegance. The façade helped transform the old building into a highly valued property because it sold for $36 million shortly after the renovation

was completed.

Libraries and art buildings

Channel glass can be a stunning alternative to traditional rainscreen wall systems. These assemblies create virtually seamless, luminous glass walls of unlimited lengths. The self-supporting glass channels can stand as tall as 7 m (23 ft), require minimal framing, and create expansive ventilated rainscreen façades, which can withstand high wind loads.

The Carbondale Branch Library in Colorado is outfitted with such a ventilated channel glass façade atop its entrance. It shields the open walkway against wind-driven rain and snow.

In Boston, the award-winning Institute of Contemporary Art’s upper level is enveloped with a channel glass rainscreen on three sides. It serves as a protective barrier against harmful moisture, while adding sophistication and style to the building.

[11]

[11]Utility structures

The World Trade Center’s Vent D structure is a utilitarian edifice, framed by Greenwich Street to the east and the future World Trade Center’s fifth tower to the south. It provides ventilation for the parking structure below New York City’s new Liberty Park.

The vent’s location, atop an elevated walkway in the southeast corner of the park, required an elegant design to complement the landscaped surroundings and neighboring buildings. A ventilated glass façade system was the ideal solution. The brilliant white glass creates an attractive, luminous exterior, while offering passive ventilation and moisture protection. Fritted glass was selected for its added durability. Exposed to the elements, its colors resist chipping and fading better than applied color coatings.

Glass ventilated façade systems are now highly recommended for low-, mid-, and high-rise buildings. A recent example of a high-rise application is One Hudson Yards in New York City. The utilities on the roof of this luxury residential tower are concealed behind a ventilated, back-lit glass façade, using white laminated glass and mechanical attachments.

[12]

[12]Photo © Christopher Mullen

Parking structures

Innovation in building systems is fueling a transformation in parking design. Previously viewed as architectural eyesores, these buildings have recently evolved into impressive modern structures, offering improved aesthetics, occupant comfort, and safety.

Ventilated glass façades on parking decks, stairways, and elevator towers provide visual and acoustic openness, light, and passive ventilation. Unlike opaque walls, these open-joint glass systems are able to maintain unobstructed views and daylight—key contributors to the safety of building users.

According to U.S. Department of Justice studies, parking structures should be designed with open façades to help prevent crime. (For more information, read Mary S. Smith’s “Crime Prevention Through Environmental Design in Parking Facilities” at www.ncjrs.gov/pdffiles/cptedpkg.pdf[13].) Research findings highlight the need to ‘permit any individual in the stair or elevator lobby to be seen from the outside.’ Open, see-through glass cladding systems maintain clear sightlines, allowing users to see and be seen from multiple angles. They also allow users to hear and be heard, making them more alert to their surroundings.

A well-designed ventilated glass façade[14] system can prevent as much as 90 percent of wind-driven rain from reaching and damaging building components behind the cladding layer. It can also provide sufficient passive ventilation to completely eliminate the need of mechanical ventilation systems for parking decks, stair, and elevator towers. Some systems can accept shingled or louvered glass panels to balance moisture protection with the need for maximum ventilation.

Conclusion

We are now experiencing an unprecedented influx of highly innovative building materials and systems. Among them, ventilated glass façades with superior performance and unique daylighting capabilities are quickly becoming a preferred choice for building professionals. The sophistication and aesthetic appeal of these systems can easily elevate the appearance and prestige of buildings (new or old), right from parking structures and mass transit stations to luxury high-rises.

| A VENTILATED GLASS FACADE PROVIDES MULTIPLE BENEFITS |

| Performance It protects from the elements, provides passive ventilation, and offers fire safety through the use of non-combustible system components. A glass rainscreen assembly can also improve the façade’s thermal insulation properties through the addition of either rigid insulation or insulated metal panels (IMPs) behind the glass cladding. Colors, frits, decorative interlayers, and digital patterns and designs on the glass provide improved shading and solar radiation control. Even monolithic, ultra-clear (low-iron) glass blocks more than 10 percent of solar energy and 15 percent of ultraviolet (UV) energy. In laminated form, the glass can block over 99 percent of UV radiation, protecting materials behind the cladding layer against fading and discoloration.Aesthetics Transforms and elevates the building’s appearance, and the nonporous, low-maintenance glass surfaces require minimal effort for upkeep.Daylighting and visibility It preserves daylighting advantages and views through the use of transparent or translucent decorative glass cladding over openings. The material allows occupants to see and be seen for added safety and comfort, and reduces energy costs by reducing the need for artificial interior lighting.Durability Ventilated glass façades withstand punishing climates and environments better than porous façade materials, and resist permanent staining, fading, and corrosion. Sustainability Quick and easy installation |

Said Elieh is the director of technical design for Bendheim Wall Systems, and the product manager for its decorative glass rainscreens division. He has more than 20 years of construction industry experience, and holds a master’s degree in architecture. He can be reached via e-mail at selieh@bendheim.com[15].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Blu-Dot.jpg

- rainscreens: https://bendheim.com/

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/rainscreen.jpg

- pressure-equalized rainscreen assembli: http://www.rkeleher.com/documents/Pressure_Equalized_Rainscreen-Straube.pdf

- es: http://www.rkeleher.com/documents/Pressure_Equalized_Rainscreen-Straube.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Silesian-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Farmers-House-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/lotz.jpg

- www.constructioncanada.net/glass-rainscreen-systems-enhance-the-building-envelope: http://www.constructioncanada.net/glass-rainscreen-systems-enhance-the-building-envelope

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Orchard.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/hudson-e1517328136558.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/01/Carbondale.jpg

- www.ncjrs.gov/pdffiles/cptedpkg.pdf: http://www.ncjrs.gov/pdffiles/cptedpkg.pdf

- ventilated glass façade: https://bendheim.com/

- selieh@bendheim.com: mailto:selieh@bendheim.com

Source URL: https://www.constructionspecifier.com/see-rainscreens-looking-age-open-ventilated-glass-facades/