The industry-accepted method for FPSF design and construction in climates with seasonal ground freezing is American Society of Civil Engineers (ASCE) 32-01, Design and Construction of Frost-protected Shallow Foundations. This standard provides shallow foundation design principles, specific insulation design methods, and—importantly—long-term design R-values for XPS and EPS foam insulations.

The committee responsible for developing that standard completed a comprehensive, objective, and critical review of the in-service thermal performance of XPS and EPS in below-grade applications. The resulting ASCE 32-01 establishes long-term design R-values for both XPS insulation and EPS insulation for FPSFs based on analysis of internationally available research data.

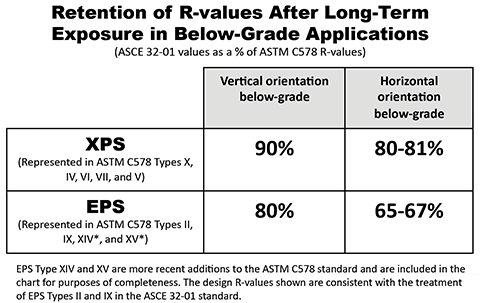

The long-term effective R-value guidelines are grouped into XPS and EPS insulations because of the higher moisture absorption resistance of XPS and the somewhat lower moisture absorption resistance of EPS. The Standard Committee established long-term design R-value guidelines for XPS and EPS insulation installed vertically or installed horizontally for FPSFs due to moisture exposure differences of the two orientations.

For XPS in vertical installations, such as at the perimeter of a concrete slab foundation, the long-term design R-value listed in ASCE 32 is 90 percent of the ASTM C578 minimum R-value specification. The long-term design R-value listed in ASCE 32 for EPS depends on the product Type (for EPS, R-value varies by type), but is 80 percent of the ASTM C578 minimum R-value specification for that product.

When it comes to horizontal installation orientations (e.g. the FPSF’s ‘wing’ insulation), the long-term design R-value listed in ASCE 32 for XPS is 80 percent of the ASTM C578 minimum R-value specification. In this instance, the long-term design R-value of EPS listed in ASCE 32 is 67 percent of the ASTM C578 minimum R-value specification for that type of EPS (Figure 4).

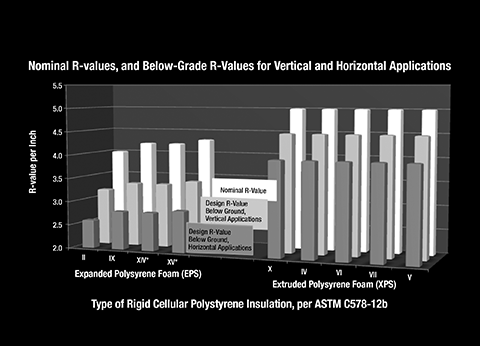

The long-term effective R-value guidelines for XPS and EPS insulations listed in ASCE 32 are shown in Figure 5. The tallest set of bars in the back of the chart illustrates the minimum R-value per inch as required by ASTM C578 for XPS (right-hand bars) and EPS (left-hand bars). The lighter gray, mid-height bars in the middle row of the chart represent the long-term design R-value in exterior below-grade vertically oriented FPSF applications, while the darkest gray or shortest bars in front of the chart represent the design R-value (per inch) for exterior below-grade horizontally oriented FPSF applications.

Sustainability considerations

Due to the thermoplastic nature of XPS insulation, virtually 100 percent of all in-plant scrap is recycled and reused in the primary extrusion process. Additionally, the XPS production process uses post-consumer and post-industrial recycled and/or recovered polystyrene foam. Generally, XPS manufacturers employ up to 30 percent recycled polystyrene in the production of XPS.

Remarkably durable and water-resistant, XPS insulation can find multiple ‘lives’ in many situations. In commercial roofing applications, XPS insulation is often reused when a new roofing membrane is installed, saving the cost of both replacement insulation and hauling removed insulation to the landfill.

Conclusion

Vegetative roofs and below-grade applications present a challenging environment for insulations because of the exposure to moisture and compressive loading. Polystyrene foam insulation products are available in a wide range of R-value per inch, compressive strengths, and moisture absorption resistance to meet these challenging below-grade insulation requirements, but it is important to remember there are fundamental and important differences between XPS and EPS.

When considering the two materials for applications where moisture absorption resistance is critical, it is important to select the appropriate ASTM C578 type of XPS or EPS based on thermal performance, compressive strength, durability, and moisture absorption resistance. It is also important to specify the appropriate insulation thickness based on ASTM C578 minimum R-value specifications and with consideration given to long-term thermal performance.

John Woestman is director of codes and standards for the Extruded Polystyrene Foam Association (XPSA). He has more than 25 years of experience in the construction and building products industry with various responsibilities in construction, manufacturing, human resources, marketing, and codes, standards, and regulations. Woestman has a diploma in building trades, a degree in mechanical engineering, and an MBA. He is a member of the International Code Council (ICC), ASTM, and the National Fire Prevention Association (NFPA). Woestman can be reached at jwoestman@xpsa.com.

I visited many websites except the audio feature for audio songs current at this site is in fact excellent.