Forming/assembly options

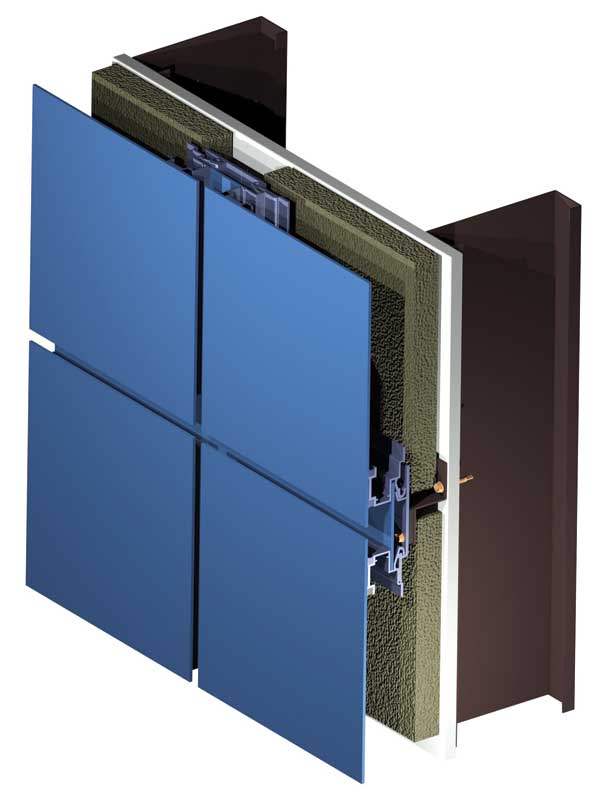

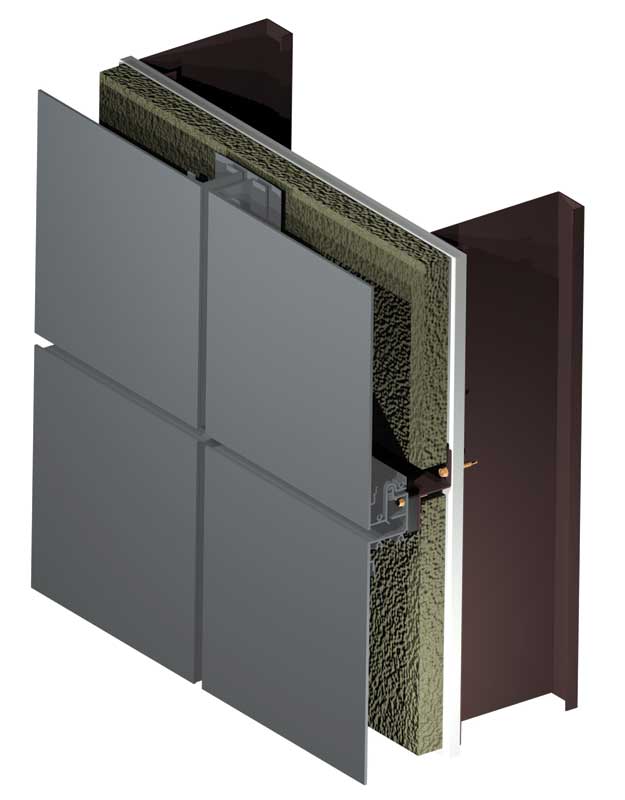

Solid metal rainscreens can be assembled using large-format flat plates installed on an engineered extruded aluminum frame platform. This method enables designers to provide a ‘floating plate’ appearance with crisp edges, clean lines, and bold reveals. The most popular panel joint options are:

- spline-reveal perimeter;

- hook and pin; and

- stacking male/female joinery.

The panels can also be curved or segmented over vertical walls or undulating surfaces (Figures 1 and 2).

Metal is flexible and can be formed to an array of edge conditions and radii to create softer edges and projecting features. Formed metal panels are usually produced with welded corner folds and miters. They can be polished smooth prior to finishing, thereby presenting a seamless edge appearance. This method of forming is often employed in projects where occupants and pedestrians could come into direct contact with the panels (Figure 3).

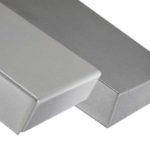

Prefinished aluminum, copper, stainless steel, and zinc are all highly economical choices for repetitive, smaller-format panel profiles. In this ‘plank-style’ configuration, edges are folded into interlocking profiles to reduce the number of components, which in turn brings down installation costs. Additionally, prefinished colors can be mixed and matched to create random or repeating color schemes in a highly efficient manner (Figure 4).

Solid metal plate

Metal plate offers a high degree of impact/scratch resistance when subjected to the wear and tear typical for building façades. This option also provides a highly durable alternative for entry portals and other surfaces in close proximity with pedestrians and occupants.

If damaged beyond repair, individual panel sections can be easily removed and replaced. Figure 5 provides a good reason to select solid metal as a substrate for rainscreen designs. The photo shows metal composite material (ACM) panels—thin sheet metal outer facings bonded to plastic cores—are prone to denting.

Solid metal plate is noncombustible and nontoxic when exposed to flame. It does not contain volatile organic compounds (VOCs), and no plastics or petrochemical feedstocks are employed in constituent components. Produced from homogenous naturally occurring ores, the material is recyclable at the end of its life cycle.