Positive drainage

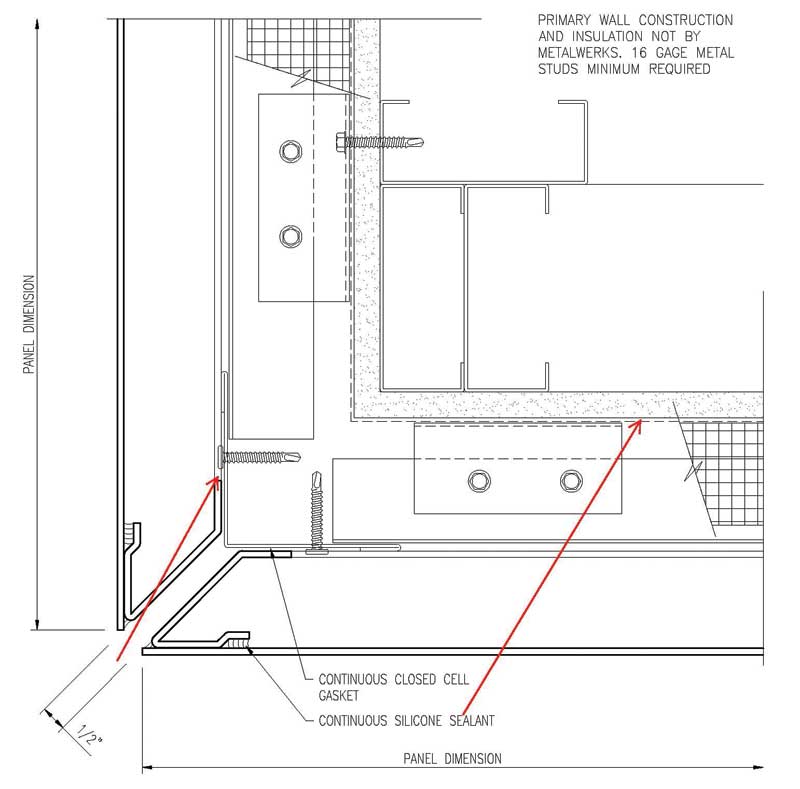

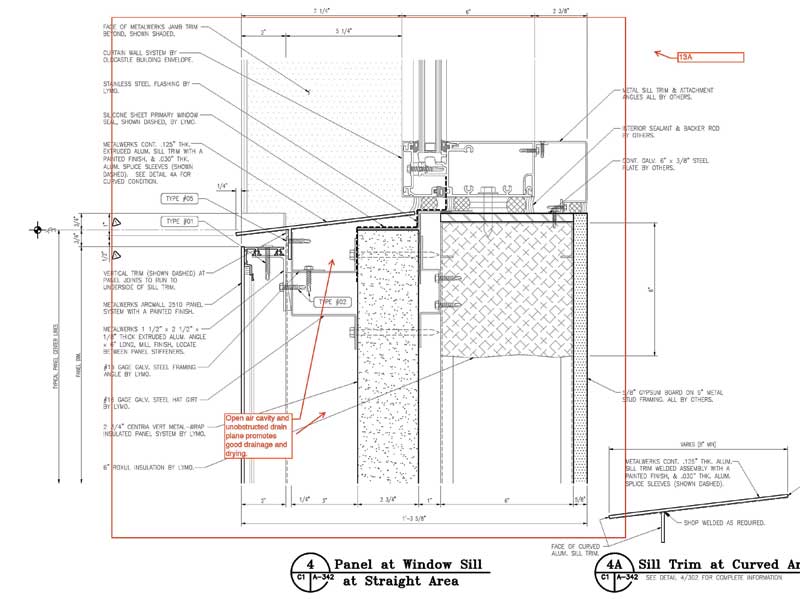

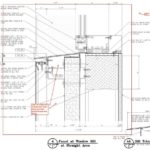

One of the most common errors seen in metal rainscreen design is the unnecessary interruption of the drain plane by supplemental framing for projecting elements or slab-edge projections. Protecting the air barrier from penetrations and changes in direction decreases the risk of costly maintenance. Whenever possible, arrange attachment clips and fastener penetrations in the vertical surfaces of the wall substrate to promote good drainage and migration to the exit points of the wall system. Use intermittent anchor clips in lieu of continuous furring sections for metal rainscreen panel attachment. This way, moisture can traverse around the interruptions and not collect at or near fastener penetrations (Figure 12).

To ensure positive drainage along the drain plane, it is important to maintain an air space within the system for venting.

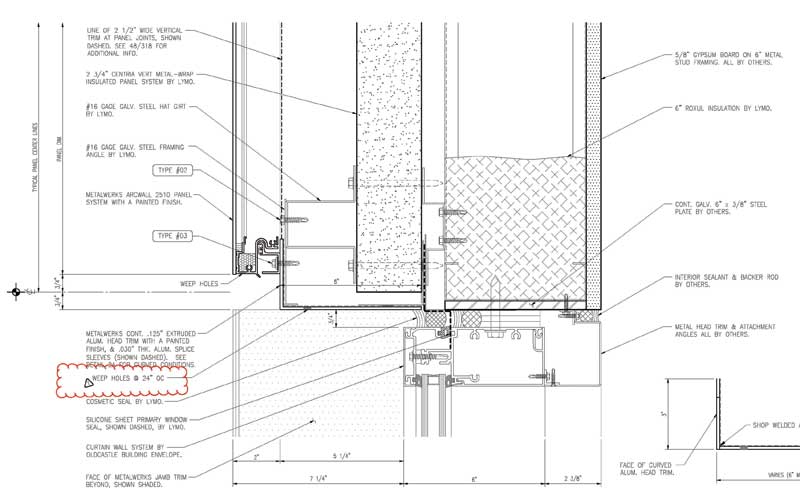

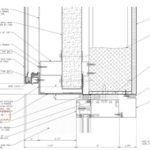

Proper ventilation is important for all types of rainscreens. Façade design must have good weeps and channeling to allow moisture to collect, drain vertically, and exit the system at the designated flashing points. These can occur at the head of any fenestration, the base of the wall system at grade, or projecting floors/roofs (Figure 13). (For a discussion on the wonders of venting, read the article “The Ins and Outs of Metal Rainscreen Wall Systems,” written by JosephW. Lstiburek, PhD, P.Eng., an American Society of Heating, Refrigerating and Air-conditioning Engineers [ASHRAE] Fellow, republished from an ASHRAE journal in May of 2008 through www.buildingscience.com. You can read it at www.smacna.org/resources/resource/2016/03/10/the-ins-and-outs-of-metal-rainscreen-wall-systems-simpson-gumpertz-heger.)

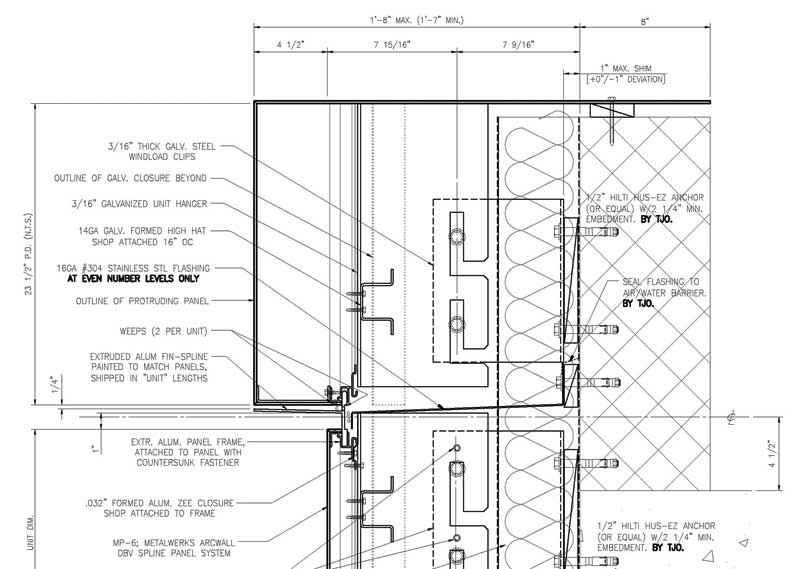

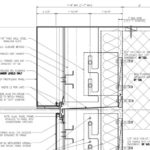

On high-rise buildings, supplemental exit points may be necessary. Accumulated moisture needs a variety of exit points to avoid the possibility of overwhelming the drainage space. Flashing this moisture to exit at every other floor is a good practice on large shear walls (Figure 14).

Performance

Perhaps the most important of all considerations during the design development of a façade is to ask what performance characteristics are essential for the client and project, set in a particular community. Some of the important performance considerations include:

- thermal performance;

- longevity of materials and resilience;

- sustainability of the design elements, as well as any constituent components;

- impact resistance/durability;

- UV resistance;

- combustibility; and

- toxicity.

A solid metal façade is highly engineered and allows the project team to meet all these criteria. Metal rainscreens also adapt well to continuous insulation (ci) and air/water barrier techniques, which are continuously evolving.

Overall performance of a rainscreen wall system is usually defined in the specification documents by the levels of moisture and air intrusion permitted to enter the cavity behind the outer metal layer, into the thermal cavity, and back to the drain plane. Open-joint rainscreens or drained and back vented are very popular because designers are given more freedom to use open-joint reveals and articulations. These designs are based on the premise the primary air and water barrier is at the drain plane.

This style of performance is defined in testing under AAMA 509, Voluntary Test and Classification Method for Drained and Back Ventilated Rainscreen Wall Cladding Systems, test protocols, where water and air intrusion past the rainscreen is permissible up to a point. This testing assists in a third-party monitored measurement for a comparison of one system to another. There is no pass or fail criteria—the testing is merely a measurement regime involving qualitative analysis of air and water intrusion past the outer layers of the rainscreen components and back to the air and water barrier.

A more conservative approach is to follow the pass/fail protocols that are found in AAMA 508, Voluntary Test Method and Specification for Pressure Equalized Rainscreen Wall Cladding Systems, which dictates prescriptive permissible limits for air and water intrusion and pressure equalization intervals, accompanied by dynamic structural testing. Systems passing this stricter testing are considered PERS-certified and are generally more costly to produce and install. The extra components necessary to baffle wind-driven rain, vent, and provide guttering for moisture management behind the outer leaf lead to this increased cost. For the same reasons, these systems may also require additional wall thickness space. Selecting the appropriate level of performance for the project is important. (For an in-depth review of these two test protocols—pressure equalized AAMA 508 vs drained and back vented AAMA 509—there is a handy comparison bulletin published by Architectural Testing, a high-quality third-party independent testing lab. Read it at buildingscience.com/documents/insights/bsi-004-drainage-holes-and-moderation.)

Conclusion

The design and installation of solid metal rainscreen systems requires a high level of technical attention and experience, and there are many critical details to consider. The seven Ps discussed in this article can help ensure a successful design and consistent installations. Offering high performance, longevity, sustainability, and design options, solid metal rainscreens can help solve the common façade issues of the past. Architects and designers seeking a product for moisture mitigation, pressure equalization, air and water barrier, thermal performance, and low maintenance can consider metal rainscreens.

Stephen J. Scharr, Esq. is a business development professional with Metalwërks, a manufacturer of architectural metal façades and features. He was president of Metalwërks for more than 20 years. Scharr is also a licensed attorney specializing in construction-related issues. He has provided legal liability and contract consulting services for manufacturers and specialty contractors. In 2014, Scharr co-authored a section of the book, Construction Subcontracting: A Comprehensive Practical and Legal Guide, published by the American Bar Association (ABA). Scharr is a member of ABA’s construction forum and the Pennsylvania Bar Association. He can be reached via e-mail at stevescharr@metalwerksusa.com.