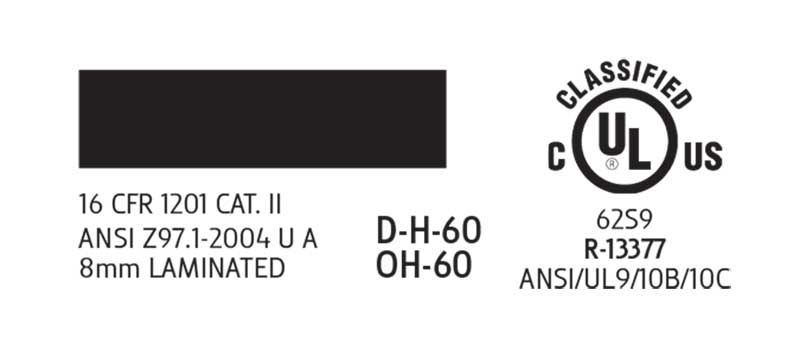

| READING FIRE-RATED GLASS LABELS |

The 2012 International Building Code (IBC) requires fire-rated glazing to include a multi-faceted product label code that building and design professionals can reference to quickly evaluate a product’s performance capabilities. To guide appropriate use, it is necessary to understand what these markings mean, and what implications they have for specification. The first part of the label code is a letter indicating which applicable test standard the glass has passed, and where it is considered suitable for use:

The next two letters in the code sequence, if present, will indicate conformance with certain test criteria:

The last marking on the fire-rated glazing label is a two- or three-digit number showing the fire rating in minutes (e.g. 45, 90, or 120). The given number corresponds with manufacturer testing in accordance with national fire test standards. Thus, when the product label code is read, it is possible to quickly determine whether a given product has passed the necessary tests for the fire door application at hand. For example, when looking at the sample fire-rated glass label above, the “D-H-60” and “OH-60” designations show the product:

If a fire-rated glazing product has been tested to multiple standards, as evidenced in the sample label, it carries multiple markings indicating its suitability for those uses. |

Jeff Razwick is the president of Technical Glass Products (TGP), a supplier of fire-rated glass and framing systems, and other specialty architectural glazing. He writes frequently about the design and specification of glazing for institutional and commercial buildings. Razwick is a past-chair of the Glass Association of North America’s (GANA) Fire-Rated Glazing Council (FRGC). He can be contacted via e-mail at jeffr@fireglass.com.

I like what this article mentions about a common application for a fire-rated door being exits. I’m wanting to get new doors and I think that focusing on safety could be better than cosmetics as a fire resistant door could really help avoid disasters. I’ll have to remember to pay attention to where I’m having them installed to make sure they’re in optimal places. Thanks for sharing!