Seven questions to ask when specifying fire-rated glazing in doors

by Katie Daniel | August 5, 2016 9:30 am

by Jeff Razwick

Fire-rated doors provide around-the-clock protection to help ensure people can safely exit a building in the event of a fire. When specified with fire-rated glazing, they can also help preserve sight lines and support aesthetic goals.

During a building fire, properly functioning fire-rated door assemblies play a critical role in providing occupants with safe means of egress. They allow individuals to pass by, or through, them without experiencing serious injury, and enable fire safety personnel to enter a structure and help extinguish flames and smoke.

Fire-rated door assemblies may service a building for years without being called into such action. As a result, it is important for them to support a building’s daily functional and aesthetic needs. To ensure all goals are met, an increasingly popular design solution is to incorporate fire-rated glazing wihtin fire-rated door assemblies.

Fire-rated glazing may be clear and wireless, with a surface quality comparable to ordinary window glass. It is available with fire ratings ranging from 20 to 180 minutes, and advanced products can provide supplemental performance benefits, such as impact and bullet resistance. With proper specification, fire-rated glazing can work in conjunction with its surrounding door components to defend against fire, while improving visibility, increasing daylight transfer, and furthering the building’s aesthetic goals.

While this is typically not an overly complex process, building and design professionals may not be familiar with the nuances of this life-safety product. To help guide the process, this article offers seven questions to ask when it is time to specify fire-rated glazing in fire doors.

1. Where will the fire-rated door be installed?

The International Building Code (IBC) uses factors such as construction type, occupancy, and fire separation to determine fire-rated door specifications. As such, an important starting point when working with designs that call for fire-rated glazing in fire doors is

to determine where the assembly is to

be installed. Examples of applications possibly requiring fire-rated doors include:

- exit passageway walls;

- exit enclosures;

- exit stairways;

- fire partitions; and

- corridor walls.

Once the location of the fire-rated door installation has been determined, it is important to review the provisions set out in the applicable building code to identify which type of fire-rated glazing is best suited for use. The 2012 IBC lays out in a clear, easy-to-read table (i.e. Table 716.3), fire-rated glazing specifications for each type of assembly, including the required fire rating, type of fire protection (e.g. “fire protection” or “fire resistance”), applicable fire tests, and vision panel sizes.

Although IBC has made great strides in making its fire-rated glazing code provisions clear to readers, there may still be instances where questions arise. To avoid making a costly or dangerous mistake, one should contact the manufacturer, supplier, or code official for additional clarification. Many have the educational resources and tools available to help simplify the design and specification process.

2. Is the door subject to temperature-rise criteria?

A crucial next step in the specification process is to determine whether a

fire-rated door assembly is subject

to temperature-rise criteria. Fire-rated doors tasked with meeting this stringent performance criterion are required

to protect against the spread of flames and smoke for their designated fire rating, as well as limit heat transfer from one side of the door to the other. This helps ensure occupants can still pass by a door to exit a building if temperatures reach high levels on the ‘fire side’ of the door. Doors providing this critical level of protection do so by preventing temperature rise on the non-fire side of the door assembly from exceeding 232 C (450 F) above the ambient temperature at the end of the first 30 minutes.

While design professionals can specify fire-protective glazing in doors with temperature-rise criteria, it is subject to area and size limitations under IBC. In instances where greater visibility and large glass sizes are desired in doors with temperature-rise requirements (as discussed in this article’s Question 5), fire-resistive glazing is often specified. The glazing typically incorporates multiple layers of glass that sandwich an intumescent interlayer that turns opaque and foams up during a fire. This internal reaction allows the glass to carry fire ratings up to 90 minutes in door lites, and remain relatively cool on the non-fire-side of the glass for the duration of its fire rating. It is suitable for use in walls, doors, and other fire-rated assemblies where it is necessary to limit heat transfer.

Photo courtesy TGP

3. Has the glass passed all required tests?

Once fire-rated door criteria have been established, it is critical to verify the fire-rated glass product has passed all required tests outlined in the building code. To help simplify this process and ensure correct specification and installation, the 2012 IBC requires fire-rated glass labels to include a multitude of information, including:

- product name;

- basic characteristics (e.g. tempered, laminated, etc.);

- compliance with impact safety requirements; and

- whether it is listed by an independent testing agency, such as UL.

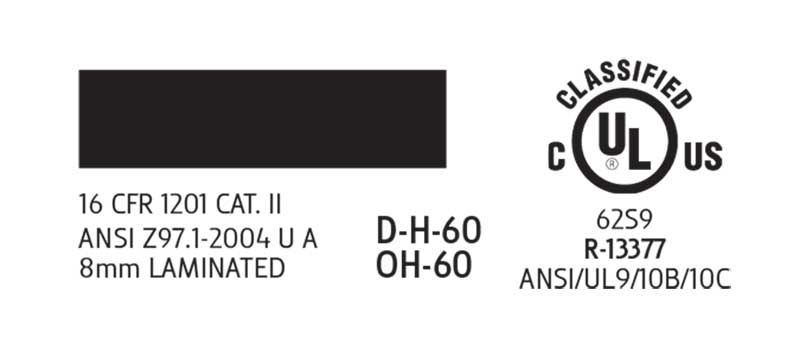

The 2012 IBC also requires fire-rated glazing to carry a set of four markings quickly referenced by inspectors, code officials, specifiers, the fire service, and other building industry professionals to identify its fire-rated capabilities. (See “Reading Fire-rated Glass Labels.”) According to 2012 IBC Table 716.3, “Marking Fire-rated Glazing Assemblies,” these markings indicate the following:

- whether it is suitable for use in doors, openings, or walls;

- conformance with the required hose stream test;

- conformance with any temperature rise criteria; and

- approved fire-rating (in minutes).

There is also fire-rated glazing that has passed tests for impact-safety testing (required for door lites), as overviewed in Question 4, and optional tests such as bullet-resistance. These tests depend on the specific application in which the product is used.

Additionally, after evaluating the fire-rated glazing material and its compliance with building codes, the manufacturer’s or supplier’s product literature should be reviewed in detail. It is important to look for any special requirements, limitations, or exclusions. For example, one should consider being wary of any materials requesting an exemption or specific Authority Having Jurisdiction (AHJ) approval for not complying with the mandatory test or building code criteria. Such products warrant closer inspection to ensure they provide the necessary level of fire and life safety protection.

Photo courtesy Heidi Gumula-DBVW Architects

4. Does the specified glass meet impact safety criteria?

Starting with the 2006 IBC, fire-rated glazing in all hazardous locations, as specified in the code’s Sections 2406.4.1 through 2406.4.7, must also pass an impact safety test. As doors are often subject to human impact and installed in hazardous locations, all glazing in doors must meet this impact-safety criteria. Fire-rated glazing adjacent to or nearby the door (e.g. side lites or glass located near the floor) is also typically required to comply with these standards.

When it comes to fire-rated glass specification, this means traditional wired glass is no longer suitable for use in fire-rated door assemblies or glass applications required to meet impact safety criteria by code. The absence of a fire-rated glazing material with the desired impact safety performance had long led code officials to grant an exemption that allowed traditional polished wired glass—which can only withstand about 14 kg/m (100 ft/lb) of impact (comparable to a five-year-old child running into the glass)—to be used in areas requiring fire protection and high-impact safety protection. However, when this exemption was lifted, building industry professionals were restricted from using what had become their ‘go-to glass’ in fire-rated doors.

By 2006, manufacturers had developed clear, wireless glazing options with a high level of fire protection and impact resistance. Building and design teams can now select from products like laminated fire-rated glass ceramic and fire-resistive glazing products that provide up to Category II (i.e. Consumer Product Safety Commission [CPSC] 16 Code of Federal Regulations [CFR] 1201, Safety Standard for Architectural Glazing) impact-safety ratings. These products either do not shatter, or shatter in a safe pattern when struck by an object comparable in impact to a full-grown, fast-moving adult.

5. Is visibility through doorways critical to occupant wellbeing?

Where the architect or building owner desires a full-lite, fire-rated glass door to maximize natural light, improve wayfinding, or allow first responders to quickly see in and evaluate potential threats during a fire event, a fire-rated glazing solution is almost always available.

For example, fire-protective glass can often be used in the maximum size (as tested/listed by an independent testing agency) in fire doors with 20- or 45- minute ratings. Fire-resistive glass is an alternative when fire-protective glass is subject to area and size limitations, as may be the case in doors with temperature-rise criteria.

Fire-resistive glass is tested to ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, and is therefore suitable for use in all doors (including those with temperature-rise door applications), without any size limitations beyond what has been tested and certified/listed by the manufacturer. Remarkably, even though fire-resistive glass features a multi-laminate makeup, many products still offer nearly the same level of visual clarity as ordinary float glass. As such, it can bring exceptional visibility to doors with stringent fire and life safety criteria.

Photo courtesy TGP

6. Will the door be installed as part

of an overall assembly?

To provide effective fire protection, fire-rated glass must be installed into an appropriately rated door and lite kit, surrounding frame, and fire-rated door hardware. If any of the door’s components have a rating below the code minimum, the fire protection of the entire assembly is in jeopardy. For example, if a 20-minute fire-rated glass lite is installed in a 60-minute fire door, the glazing may fail prematurely during a fire and create a pathway through which flames and smoke can spread. To this end, IBC requires all components to have the same or greater ratings than the required code minimums for the opening.

7. What are the aesthetic considerations?

Today, thanks to manufacturing advances, design teams can use fire-rated glass doors to further aesthetic goals while still ensuring people can safely exit a building in the event of a fire.

For example, while traditional hollow-metal steel fire door and frame assemblies can provide the necessary fire protection, the frame profile size, color, or material may not match neighboring windows and curtain walls. New-generation fire-rated steel frames can help overcome this challenge with their sleek aesthetic. Manufacturers form the frames in an extrusion-like process that results in thin profiles, well-defined edges (rather than rounded profiles), and vertical-to-horizontal framing joints without visible weld beads or fasteners.

As an added benefit, the frames can incorporate fire-resistive insulating materials or other thermal barriers within their core necessary to meet temperature-rise requirements, with only a marginal increase in frame profile size. This makes it possible for design teams to closely match the aesthetic and technical aspects of traditional aluminum frames in door applications requiring stringent fire protection.

Photo courtesy Heidi Gumula-DBVW Architects

Design teams can also specify fire-rated doors and frames in a wide array of colors, materials, and finishes. Popular options include custom powder coating of steel doors and frames to match virtually any color scheme. Numerous manufacturers also offer a wide variety of wood species and designs capable of incorporating fire-protective or fire-resistive glazing.

In applications where the glass’ aesthetic is the focus of the fire-rated door design, decorative surface treatments are available to preserve the product’s fire and life safety performance. For example, some fire-rated glass products can be lightly sandblasted or etched on one side while still maintaining their fire rating. Fire-rated glass can also be combined with colored or tinted decorative glass as part of an insulated glass unit (IGU). In either instance, the flexibility to alter the opacity of fire-rated glass provides a crucial, functional benefit in academic institutions and healthcare centers, where doors designated to provide fire protection by code may also need to balance light transfer with occupant privacy.

As fire-rated glass performance varies product-to-product, it is important to verify with the manufacturer or supplier whether a given fire-rated glazing product can be sandblasted, etched, or combined with decorative glass in an IGU and maintain its fire rating.

Conclusion

When fire-rated doors are not on duty combatting a fire, millions of people will pass through them without even realizing they provide fire protection. In large part, this is due to fire-rated glazing. To ensure occupants continue to reap the benefits of fire-rated glass doors, it is important to continue specifying and installing proper products. If doubts arise during the design or specification process, manufacturers or suppliers can often provide valuable insights.

| READING FIRE-RATED GLASS LABELS |

The 2012 International Building Code (IBC) requires fire-rated glazing to include a multi-faceted product label code that building and design professionals can reference to quickly evaluate a product’s performance capabilities. To guide appropriate use, it is necessary to understand what these markings mean, and what implications they have for specification. The first part of the label code is a letter indicating which applicable test standard the glass has passed, and where it is considered suitable for use:

The next two letters in the code sequence, if present, will indicate conformance with certain test criteria:

The last marking on the fire-rated glazing label is a two- or three-digit number showing the fire rating in minutes (e.g. 45, 90, or 120). The given number corresponds with manufacturer testing in accordance with national fire test standards. Thus, when the product label code is read, it is possible to quickly determine whether a given product has passed the necessary tests for the fire door application at hand. For example, when looking at the sample fire-rated glass label above, the “D-H-60” and “OH-60” designations show the product:

If a fire-rated glazing product has been tested to multiple standards, as evidenced in the sample label, it carries multiple markings indicating its suitability for those uses. |

Jeff Razwick is the president of Technical Glass Products (TGP), a supplier of fire-rated glass and framing systems, and other specialty architectural glazing. He writes frequently about the design and specification of glazing for institutional and commercial buildings. Razwick is a past-chair of the Glass Association of North America’s (GANA) Fire-Rated Glazing Council (FRGC). He can be contacted via e-mail at jeffr@fireglass.com[1].

- jeffr@fireglass.com: mailto:jeffr@fireglass.com

Source URL: https://www.constructionspecifier.com/seven-questions-to-ask-when-specifying-fire-rated-glazing-in-doors/