SlenderWall ™ is a high-performance architectural precast concrete complete cladding system that combines advanced engineering, superior aesthetics, and eco-friendly features. Designed for new construction and retrofitting projects, SlenderWall offers a lightweight, durable, and thermally efficient solution that meets the demands of modern architecture while prioritizing environmental responsibility. Learn more!

“While some architects admire the Slenderwall concept but often find themselves waiting for just the right project to use it, the truth is that Slenderwall’s versatility—in both shapes and finishes—makes it suitable for a wide range of building designs created every day,” says Chris Reese, Easi-Set Worldwide

Key Benefits of SlenderWall

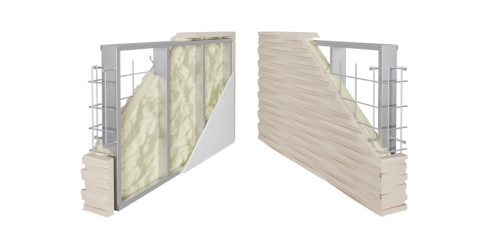

Lightweight Design

The SlenderWall precast building panels are a complete unified system, inside and out. Steel-stud framing, ready for drywall and windows, and continuous insulation, the panels, which at a weight of only 30 pounds per square foot, provide a precast building panel that is 66% lighter than traditional precast. This reduced weight lowers structural loads, enabling cost savings in foundation and framing materials while simplifying installation. The lightweight design also minimizes transportation requirements, contributing to reduced carbon emissions.

Exceptional Durability

Constructed with high-strength precast concrete and corrosion-resistant stainless-steel reinforcements, SlenderWall is built to endure harsh weather, seismic activity, and long-term exposure. This durability ensures a longer lifespan and reduces maintenance and replacement costs over time. It is approved for use in High-Velocity Hurricane Zones and is engineered to last into the 22nd century and beyond.

Superior Thermal and Acoustic Performance

SlenderWall integrates factory-installed insulation with an R-value of up to R-30, significantly improving thermal performance. This reduces heating and cooling energy demands while enhancing interior comfort. Additionally, its sound-dampening properties provide excellent acoustic insulation, making it ideal for busy urban environments.

Time and Cost Efficiency

Pre-engineered and factory-finished, SlenderWall panels streamline construction timelines by reducing on-site labor and ensuring precise quality control. The efficient design minimizes material waste during production and installation, saving both time and resources.

Aesthetic Versatility

Available in a variety of textures, colors, and finishes, SlenderWall allows architects and designers to achieve their creative vision without sacrificing performance. The system’s flexibility makes it suitable for a wide range of applications, from commercial buildings to educational facilities and residential developments.

Sustainability features of SlenderWal

Reduced Resource Consumption

Produced in a carefully controlled factory setting, SlenderWall maximizes material efficiency, greatly decreasing waste in contrast to traditional techniques. Its lightweight structure employs as much as 50% less concrete than standard cladding systems, thereby minimizing the ecological footprint of raw material extraction, manufacturing, and distribution.

High Thermal Efficiency

Built-in insulation enhances energy efficiency by reducing thermal bridging and minimizing heating and cooling demands. This not only lowers operational energy costs but also reduces greenhouse gas emissions throughout the building’s lifecycle. The integrated insulation eliminates the need for additional materials, simplifying installation and further minimizing resource use.

Low Embodied Carbon

Locally sourced aggregates further decrease the environmental footprint, aligning with sustainable construction practices.

Recyclable and Reusable Components

Precast concrete is fully recyclable at the end of its lifecycle, and SlenderWall’s stainless-steel anchors and subframes can be separated and reused or recycled. This makes SlenderWall an excellent choice for projects embracing circular economy principles.

Reduced Transportation Impact

The lightweight design of SlenderWall requires fewer transportation trips, cutting fuel consumption and carbon emissions associated with logistics. This advantage translates into both environmental and economic benefits.

Improved Indoor Environmental Quality (IEQ)

SlenderWall panels are free of VOCs, ensuring they do not release harmful chemicals into indoor spaces. By creating a tighter building envelope, this system prevents drafts, moisture intrusion, and condensation, contributing to healthier and more comfortable indoor environments.

Durability and Longevity

The exceptional durability of precast concrete reduces the frequency of repairs and replacements, lowering the environmental impact of maintenance over the building’s lifespan. SlenderWall is engineered to withstand extreme weather, freeze-thaw cycles, and UV exposure, ensuring reliable performance for decades.

Contribution to Green Building Certifications

SlenderWall supports projects seeking certifications such as LEED by contributing to key sustainability metrics. Its energy efficiency, material optimization, and waste reduction can help earn points in categories like:

- Energy & Atmosphere: Enhanced energy performance.

- Materials & Resources: Inclusion of recycled content and reduced material use.

- Indoor Environmental Quality: Improved air quality and occupant comfort.

Applications/Projects

SlenderWall is ideal for various building types and applications, including:

- Commercial buildings

- Healthcare facilities

- Educational institutions

- Multi-family residential properties

- Recladding

With its combination of aesthetic versatility, engineering excellence, and commitment to sustainability, SlenderWall is redefining modern construction. It’s the perfect solution for developers and architects seeking to build high-performance structures without compromising environmental responsibility.

Why choose SlenderWall for sustainable cladding?

By leveraging the inherent sustainability features of precast concrete and enhancing them through innovative engineering, SlenderWall redefines eco-friendly construction. It reduces the carbon footprint of buildings, improves energy efficiency, and promotes resource conservation without compromising on design flexibility or durability.

Architects, developers, and contractors choosing SlenderWall can trust they are investing in a product that balances cutting-edge performance with environmental stewardship, making it the first choice for modern, sustainable construction projects.

“In today’s market, with rising costs and a reduced labor pool, more and more architects and owners are choosing SlenderWall because they want a panelized system that reduces job site labor and speeds up construction times but also gives them huge flexible design capabilities with a “Class A” precast concrete finish. SlenderWall gives them the best of both worlds.” – Matthew Smith, Smith-Midland Corporation – a manufacturer of SlenderWall

With SlenderWall, sustainability and innovation converge, to deliver a cladding solution that meets the highest performance, aesthetics, and environmental responsibility standards.

Download a brochure or contact us to learn more.

All information listed in this section was submitted by Easi-Set Industries.

Kenilworth Media Inc. cannot assume responsibility for errors of relevance,

fact or omission. The publisher does not endorse any products featured in this article.