Panel discussion

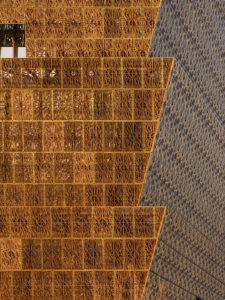

Once the final color idea had been selected, the new challenge of obtaining the perfect hue began. Three custom shades (African Sunset, African Sunrise, and African Rose) and one standard shade of black were chosen for the 70 percent polyvinylidene fluoride (PVDF) coatings used on these massive aluminum panels, each weighing around 90 kg (200 lb) and stretching 1.2 by 1.5 m (4 x 5 ft).

“The color-matching period lasted for more than 18 months because we were looking for depth even more than just color since the panels were so intricate and unique,” said Del Stephens, president/CEO of the project’s metal panel applicators.

To achieve the exact bronze shade desired by the design team, each custom-cast panel was finished with five different coating layers, each a different color of the PVDF coating. The individual coatings needed to hold their color across every layer on the panels, as each new additional color is built off the last to create the final shade.

Extensive testing was done during the coating application process, due both to the sheer size of the panels and the intricate design already cut into each piece. The coating was applied entirely by hand, and each color layer was carefully inspected to ensure every part of the coating process was on track. The process was replicated for all 3600 panels—the team worked furiously to finish them in an identical fashion and ship them from the workstation in Portland to the D.C. project site. After a bit of back and forth, the panels and their many layers of custom colors were approved and deemed ready for installation.

“What we ended up with gave us the look of real bronze—a luminous feeling that created a dynamic and beautiful façade,” said Howard.

The first panels went up in April 2015, and the build process moved forward rapidly over the ensuing months.

“The installation process went very smoothly,” said Marty Antos, project manager at Northstar Contracting, which oversaw the installation process. “This was a completely new way of installing panels, as the building is almost inside-out, with the glass on the inside and the ornamental structures, the metal panels, on the outside.”

The panels were installed within six weeks on the project site, but the assembly process took a bit longer, spanning more than one year. This was largely due to the amount of materials coming to Cleveland from across the nation, including castings from Seattle, steel frames from New Jersey, and aluminum extrusions from Missouri.

The filigree is an eye-catching adornment that both draws visitors in and sets the stage for the rest of their journey through the museum. It combines polish, artistry, creativity, and persistence—just like the art, history, and culture memorialized within the building. The museum itself is a work of art, one that stands out among the historic structures to its left and right, and will act as a physical representation of the African American history.