Solid timber, solid construction performance

by Katie Daniel | February 5, 2016 12:18 pm

by Ryan E. Smith

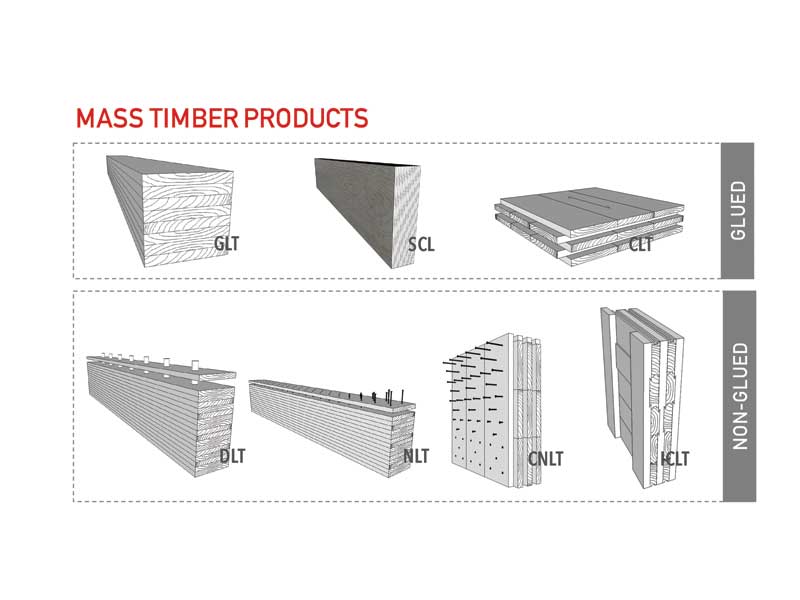

Solid timber construction, sometimes called ‘mass timber,’ is an emerging set of engineered wood products—massive planar or frame elements used for walls, floors, roofs, partitions, and core elements of a building. As shown in Figure 1, examples include both glued configurations liked glued-laminated timber (glulam), structural composite lumber (SCL), and cross-laminated timber (CLT), as well as non-glued products like dowel-laminated timber (DLT); nail-laminated timber (NLT), cross-nail-laminated timber (CNLT), and interlocking cross-laminated timber (ICLT).

These mass timber products also have the potential to utilize both traditional graded lumber and other ungraded timber, including beetle-killed and salvaged trees. Employing salvage material presents an opportunity to reduce the impact of treating hazardous fuels and the removal of other woody biomass in forests.

Construction with solid timber elements optimizes the inherent structural behavior of wood, creating a more homogeneous structural product. As mass wood products, these building materials are manufactured from an entirely renewable resource that, when compared with steel and concrete counterparts, has the capacity to sequester carbon in the structure of buildings and to reduce the negative environmental impact of construction on the planet.

Solid timber construction is fabricated offsite in a factory, and is therefore able to leverage the advantages of automation and process control—advanced machinery and measurement devices, reduction of onsite waste, and reduced construction duration from concurrent scheduling of site and factory work.

The added value of solid timber, although conceptually strong, has yet to be significantly demonstrated through objective analysis. A recent study performed by a research team at the University of Utah’s Integrated Technology in Architecture Center, aims to change that by demonstrating the qualitative and quantitative performance of such materials. This article summarizes the report quantifying and qualifying the impact on the delivery of commercial facilities. (The study, “Solid Timber Construction: Process, Practice, Performance,” was sponsored by American Institute of Architects (AIA), FPInnovations, and U.S. Department of Agriculture (USDA) Forest Products Laboratory. To access the full report, visit www.rethinkwood.com/sites/default/files/Solid_Timber_Construction_Report_August_2015.pdf[1])

Method of the study

The research team collected case studies of the following mass timber projects built around the globe:

- Bridport House (London, England);

- Bullitt Center (Seattle, Washington);

- Carlisle Lane Lofts (London, England);

- Centre for Creative Competitive Design (Bedfordshire, England);

- Elkford Community Centre (Elkford, B.C.);

- Fort McMurray Airport (Fort McMurray, Alberta);

- Forté (Melbourne, Australia)—shown under construction at left;

- Holy Trinity Primary School (London, England);

- The Long Hall (Whitefish, Montana);

- Massive Living (Graz, Austria);

- Open Academy (Norwich, England);

- Smart Price House (Hamburg, Germany);

- SmartLIFE Centre (Cambridge, England);

- Tamedia Office Building (Zurich, Switzerland);

- University of British Columbia (UBC) Earth Systems Science Building (Vancouver, B.C.);

- UBC Okanagan Fitness & Wellness Center (Kelowna, B.C.);

- Via Cenni (Milano, Italy); and

- Wagramerstrabe (Wien, Austria). (For more on the Bullit Center, see The Construction Specifier’s November 2013 issue for “Window and Storefront Thermal Performance,” by Brian Stephens. Visit www.constructionspecifier.com/window-and-storefront-thermal-performance-what-every-specifier-needs-to-know[2]. In-depth case studies on the two UBC projects have appeared in Construction Canada. Visit www.constructioncanada.net[3])

For each project, cost, schedule, scope, quality, and safety data was collected from three stakeholders: architect, general contractor or construction manager, and the timber fabricator and/or supplier. In addition to quantitative data, the stakeholders were asked qualitative questions to determine the context for successful employment of solid timber construction.

Of the 18 case studies for which data was collected, 11 had substantial contributing cost and schedule information. Of these, seven had direct traditionally built projects to which they were compared in schedule and cost. Data from the timber projects was compared to benchmark project data supplied by Cumming Corp., a cost consultancy firm. The benchmark data was concerning traditional site-built construction in steel and/or concrete.(The data for both the timber cases and the traditional comparison cases were normalized to the first quarter of 2014 with Washington, D.C., as the location. Units of cost were calculated per square foot, and it was assumed all the traditional benchmark construction projects in comparison used a design-bid-build delivery system. When possible, estimates for the comparisons were based on actual items of work. When data was unavailable, precedent values from other projects were interpolated for these comparative projects. Unit costs are based on current bid prices in Washington, D.C., with subcontractor overhead and markups included. General contractor overhead and profit was separated. The traditional comparative project values were based on the probability of cost of construction at the programmatic design stage. Davis Bacon Wage Rates, RS Means Geographical Indices, and RS Means Standard Hourly Rates for Construction Industry Cumming Corporation Internal Economic and Market Report were referenced. The items not covered in this comparison of mass timber to traditional build include hazardous material abatement, utility infrastructure improvements design/consulting fees, building permitting, testing and inspection fees, and land acquisition costs.)

Quantitative results

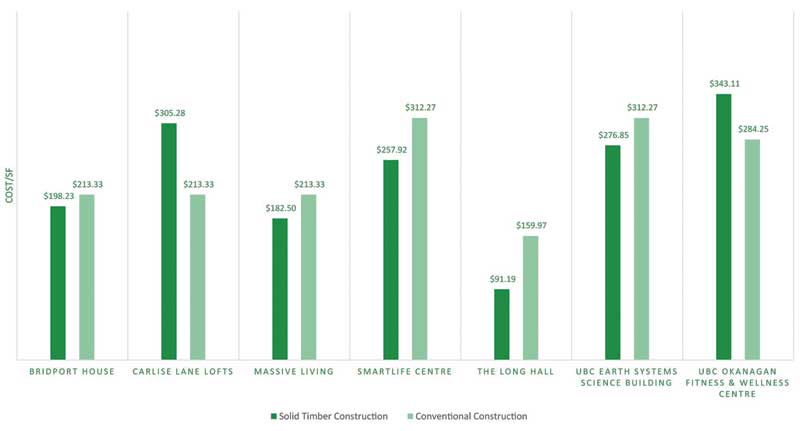

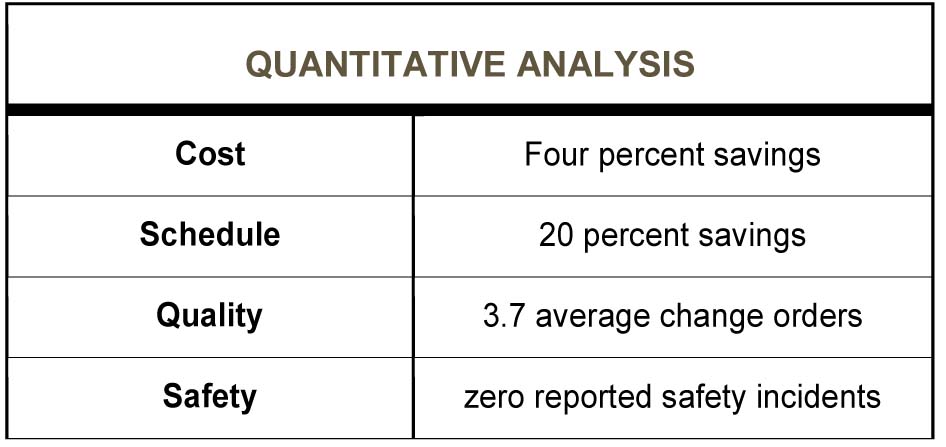

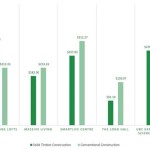

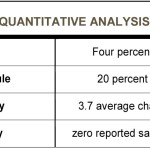

From the pool of case study projects and their traditional benchmark comparisons, mass timber had an average of four percent cost savings (Figure 2). Further, four of the seven cost comparisons were considered ‘pilot projects’ or were the first timber structures designed and constructed by their stakeholders. Among these, only two were considerably more expensive to build than traditional projects. (Those projects not considered ‘pilots’ all came in under cost to their more traditional counterparts.)

The repetition of using solid timber and building on the knowledge gained from previous projects helps streamline costs and increase productivity. This evaluation suggests one-off timber projects have a high possibility of being more expensive than traditional construction. The most important item to note in this cost analysis is timber is conducive to greater cost control when compared to traditional onsite construction. This is attributed to the inherent ability to reduce the number of change orders in any given timber project.

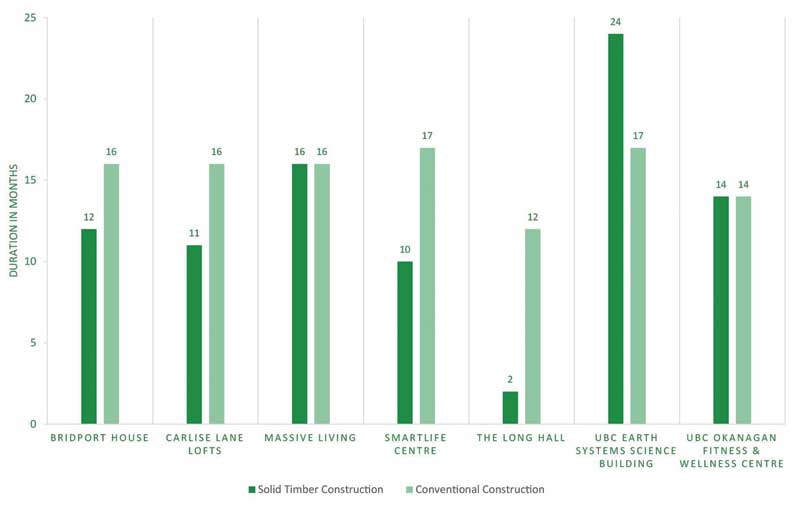

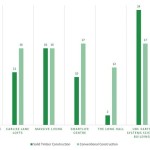

The reduction of time in the production of timber buildings is seemingly the single greatest factor this method of construction has to offer. It shows an average of 20 percent schedule reduction across the compared case studies—an average of 12.7 months compared with 15.4 months for conventional construction (Figure 3). Since the solid timber panels are built in a factory, sitework and foundations can be constructed simultaneously. This reduces the lag time a traditional site-built building has where sitework, foundations, and building construction occur consecutively.

On average, the solid timber projects took 2.9 months to fabricate in the factory, and just 60 days to erect onsite. Small amounts of labor are needed to erect solid timber. (For example, of the case studies included, Bridport House required 14 weeks to erect with only four skilled laborers and one supervisor, while Open Academy needed 16 weeks and only eight skilled laborers and one supervisor. Forté required 10 weeks to erect with only five skilled laborers, a supervisor, and one trainer.) The schedule savings open a window of opportunity for additional cost savings, such as land loan amortization accrual reductions. Further, across 11 of the case studies there were 3.7 change orders per project and no safety incidents. The quantitative results are summarized in Figure 4.

Qualitative results−Advantages

Project stakeholders were interviewed to determine the contextual parameters fostering the successful employment of solid timber. The following are the qualitative findings on the advantages of timber.

Speed

One project was erected in as little as 4.5 days. Additionally, multi-story structures can begin subcontractor work once the first story is erected (i.e. electrical, mechanical, etc.)—this cannot be done as efficiently in steel or concrete. Bridport House reduced its schedule by eight weeks compared to traditional methods, and Forté reduced its by three months.

Weather versatility

Due to the ‘dry process’ of mass timber buildings, they can be assembled during any season. Most CLT is sealed and is unaffected by snow, or water during construction.

Raw material

A majority of solid timber comes fully finished, with the ability to be exposed as an interior surface. This can cut back on finishing materials (e.g. gypsum wallboard and paint).

Carbon reduction

Wood is a carbon-sequestering material, and it greatly minimizes the carbon footprint for each project.

Remote sites

Panels are fabricated offsite, and then shipped or trucked to the site. Once delivered, they can be assembled very quickly. This method is especially helpful in rural locations, or places with a minimal labor force.

Labor costs

With manufacturing taking place in a factory, there is a reduced need for onsite labor or site preparations.

Weight

Foundations can be smaller, and buildings can be built taller for the similar costs as traditional methods of construction. This lightweight structure can also help with special site conditions such as near waterfronts and where soils may not be as favorable. Using CLT for Bridport House made it possible to double the replacement structure with only a 10 percent increase in overall weight.

Precision

With tolerances within millimeters, the connections and envelope are tight. This also increases energy efficiency.

Safety

Given the finished nature of the panels, there is less potential for injury. There are fewer parts to assemble and transport. For example, Forté, a nine-story structure, did not have a single first aid incident during construction.

Qualitative results−Disadvantages

Qualitative findings on the disadvantages of mass timber included various challenges.

Knowledge and labor

Solid timber is a very different form of construction compared to stick framing, concrete, or steel. Most general contractors, designers, and engineers are not familiar with solid timber and how it is constructed. The majority of the time, a consultant was hired, or a structural engineer familiar with the technology was procured for design assist. Special construction crews were recruited to assemble the system.

Research

Due to the lack of experience and projects completed in North America with mass timber, there is still a lack of information on construction methods, connections, and delivery methods.

Logistics

Most panels are shipped either on a truck or in a container, and each method has its own transporting capacity. Shipments must be transported to the site in order from foundation to vertical termination, with the first piece to be erected on top of the shipment. Re-arranging panels and temporarily storing them is costly and wastes time.

Planning

Due to the finished nature of CLT panels, the mechanical and electrical systems are located before fabrication. Knowing where and how these chases will affect finishes and design is crucial. In other words, designing for mass timber is a completely different process—all design work must be front loaded and completed before information is sent to fabrication. The scheduling of this process is then front-loaded, compared to traditional construction.

Acoustics and vibration

Due to the rigid nature of the panels, this construction is susceptible to sound and vibration that can be transferred through walls and floors. Extra sound-proofing is usually needed to mitigate that sound.

Job displacement

Less manpower and fewer labor hours are required for solid timber. This decreases the amount of jobs that on-site construction currently provides.

Codes and permits

Given mass timber’s newness in North America, many building officials are unfamiliar with the associated structural, fire, and acoustic performance.

This often requires more documentation, engineering, and longer time frames to get permits.

Wind

Wind is a concern when craning CLT panels from the truck to the site. Given their wide surface area, they are greatly affected by high winds. Construction can be halted to wait for weather conditions to improve.

Component flexibility

The massive panels are too heavy to handle by hand, thus requiring heavy machinery and cranes to install. This limits the amount of onsite adjusting that can be done.

Ten best practices

Best practices derived from the qualitative results of this study were wide-ranging.

1. Design to the product

Solid timber products come in set dimensions. For example, CLT panels start at 3 x 12 m (10 x 40 ft), up to 27 m (90 ft) long. Walls, floors, and roofs should be designed to maximize the yield of the standard dimensions the fabricator uses. Designers need to be educated on fabrication machine capabilities, methods, and limits.

2. Complete the design

It is difficult to make changes to a solid panel onsite, given the ‘finished’ nature of the product. The location of electrical chases and penetrations in the panel need to be designed before fabrication. This means all the designs and drawings must be complete before they are sent to fabrication.

This front loads the design process, but quickly speeds up construction.

3. Start small and scale up

A large number of the case studies surveyed were pilot projects or were using solid timber in an innovative way for the first time. Using the project as a testing ground, some stakeholders then took knowledge gained and created additional projects.

4. Talk to local AHJ early

Authorities having jurisdiction (AHJs) need to know early on in the design process the plan to build using solid timber. Additional documentation/approval may be needed. This can also help to expedite inspections and permit approval.

5. Design in 3-D

Designing in 3-D software or with building information modeling (BIM) tools provides clash detection and identifies possible problems before fabrication. This also speeds up the process for fabrication; providing a single model to all subcontractors increases consistency.

6. Remember not all trades are as accurate as CNC machinery

Some trades only come within 12 to 6-mm (½ to a ¼-in.) tolerances, while computer numerically controlled (CNC) machines have tolerances within millimeters. Connections between CNC-cut panels and onsite fabricated materials can become complicated with different tolerances. One must allow room for proper tolerances in design and fabrication.

7. Consider the finish of the timber

There are different types and grades of solid timber panels, and some even come with certain sealers or finishes from the fabricator. Understanding how panels will be exposed is critical in the design process.

8. Collaborate early

All project stakeholders (e.g. owner, architect, fabricator, manufacturer, and contractor) should be working together from the beginning. This collaboration can help speed up the project schedule considerably, and help avoid mistakes.

It is very beneficial to involve fabricators early to help with design, scope, and limitation of materials on the project. They can also assist the architect with designs and terminology of solid timber.

9. Keep logistics in mind

Transportation of panels can require additional permits and even weight requirements, depending on the travel route. One must evaluate the restrictions of shipping containers/trucks that will be enforced along the transportation route from the fabricator to the jobsite. Also, shipping wood panels between states may not be allowed due to possible introduction of invasive species or bringing foreign material into that jurisdiction.

10. Be aware of software interoperability

Coordination with fabricators prior to design regarding the applications they use to fabricate solid timber is critical. As such, architects should design to communicate with fabricator software as seamlessly as possible. Some of the most common export extensions are .SAT and .IFC file types.

Conclusion

There is seemingly a cost advantage and more certainly a schedule advantage to solid timber construction. Additionally, the material’s use demonstrates a manageable number of change orders and is seen as a safe construction delivery method. During interviews, stakeholder respondents substantiated schedule and safety benefits. Additionally, they indicated timber promotes a reduction in weight compared to steel and concrete construction, requiring less material in foundations.

The disadvantages expressed by those interviewed indicate knowledge and labor skill to handle solid timber continue to be obstacles. Additionally, much early-design-stage planning needs to occur with project stakeholders and code officials to ensure a more streamlined design phase execution. The most important best practice recommendation is early engagement of key personnel—especially the mass timber product manufacturer. This has the potential to be coordinated through a digital modeling platform using .IFC-compliant file types.

There is a market for timber, and from the project study the most efficient building types are housing, commercial/retail, or office spaces three to four stories tall or higher. Further, markets that can benefit from fast construction times, where owners can start collecting rental/lease income sooner, have a greater chance of realizing the material’s extrinsic benefits. Timber also lends itself to panelized and repetitive construction.

Ryan E. Smith is an associate professor and director of the Integrated Technology in Architecture Center (ITAC) at the University of Utah. He chairs the National Institute of Building Sciences (NIBS) Offsite Construction Council, and publishes or presents on offsite design and manufacturing. Smith is author of Prefab Architecture (Wiley, 2010) and co-author of Building Systems (Routledge, 2012). He is a senior research fellow in the Centre for Offsite Construction + Innovative Structures (COCIS) at Edinburgh Napier University in Scotland. Smith can be reached via e-mail at rsmith@arch.utah.edu[4].

- www.rethinkwood.com/sites/default/files/Solid_Timber_Construction_Report_August_2015.pdf: http://www.rethinkwood.com/sites/default/files/Solid_Timber_Construction_Report_August_2015.pdf

- www.constructionspecifier.com/window-and-storefront-thermal-performance-what-every-specifier-needs-to-know: http://www.constructionspecifier.com/window-and-storefront-thermal-performance-what-every-specifier-needs-to-know

- www.constructioncanada.net: http://www.constructioncanada.net

- rsmith@arch.utah.edu: mailto:rsmith@arch.utah.edu

Source URL: https://www.constructionspecifier.com/solid-timber-solid-construction-performance/