by Raymond Ting, PhD, PE

In the May 2012 issue of The Construction Specifier, this author wrote an article, “Cause and Effect,” which called for a cultural shift in how the architectural/engineering community approaches curtain and window wall problems.

Decades of experience have shown such glazed assemblies eventually fail under repeated occurrences of causes like loads, movement, stress fatigue, and the degradation of material properties due to aging. Therefore, conventional thinking in creating these glazed systems involves three steps:

- Anticipate these causes.

- Analyze the effects they produce (i.e. compromised structural integrity and weather-sealing).

- Design the exterior wall system to prevent such effects.

However, it would be more efficient to simply anticipate the ‘causes’ and then design to eliminate them in the first place.

Window wall assemblies are located near the slab edges and supported by horizontal structural members known as ‘tracks.’ On each floor, the track anchored to the top of the floor is known as the ‘base,’ while the one anchored to the underside of the floor slab of the upper floor is the ‘ceiling.’ Generally, a window wall has a significant price advantage over a comparable curtain wall due to erection cost savings. However, there are many unsolved functional performance problems that have persisted in the window wall industry for decades.

Problems usually occur when a wall component is required to perform more than one function or the design is changed at the terminating boundary. These two situations can often be prevented through a pair of strategies:

- functional isolation concept (FIC)—isolating one function of a wall component from taking on other roles; and

- unit design concept (UDC)—using one design on different conditions.

This two-part series examines how window wall problems can be permanently solved by eliminating the causes, rather than designing for the effects.

Exposed slab-edge design

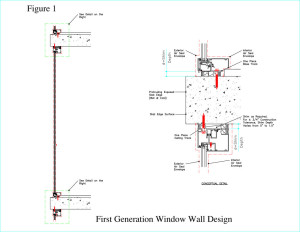

Like the image at left (or the photo above), the first generation of window walls typically employed a design that includes exposed slab edges. Unfortunately, this configuration can result in eight distinct problems.

Like the image at left (or the photo above), the first generation of window walls typically employed a design that includes exposed slab edges. Unfortunately, this configuration can result in eight distinct problems.

1. Aesthetic problem

The construction tolerances on the floor slab edges are exposed to the exterior view.

2. Durable sealing integrity problem

Critical seals between track members and the floor slab along the perimeters are executed in the field on both interior and exterior seal envelopes (i.e. double-seal design). Field quality control (QC) is difficult, while critical seals are simply ‘time bombs’ for water leakage.

3. Health problem

Due to the unsolved water leakage stated above and the double-seal design, any water infiltrated through the exterior seal envelope would be trapped within the wall cavities, potentially resulting in Sick Building Syndrome (SBS) due to mold growth.

4. Design flexibility problem

The protruding floor slab edges eliminate the flat wall option from the exterior view.

5. Structural slab problem

The exposed protruding floor slab edges are subjected to exterior weather—including ultraviolet (UV) exposure, wet/dry cycles due to rain, and freezing/thawing cycles in cold regions. This means disintegration of the slab edge concrete over time.

6. Structural anchor problem

The up/down adjustments for floor slab construction tolerances cause the masonry anchor strength to become a variable due to the changes of anchor penetration depth and the distance from the anchor head to the floor slab surface.

7. Field productivity and QC problem

The horizontal base or ceiling track is a ‘one-member design.’ Consequently, during the floor slab’s up/down adjustment, construction tolerances can only be achieved by using plastic shims. While the track member is temporarily supported in the air by the unsecured shims, anchoring holes must be drilled into the floor slab at the precise locations. This is a difficult field task, lowering productivity and possibly impacting the quality of the erected wall.

8. Water leakage problem

When the window wall terminates at a masonry wall, its terminating jamb member must provide two functions. Its sealing completes the interior and exterior seal envelopes, but its structural function is also to resist the wind load reaction. Since the masonry wall is much stiffer than the window wall’s terminating jamb member, the latter’s deflections (caused by cyclic wind loads) will cause serious sealing line stress fatigue, leading to sealing functional failure and water leakage.

Covered slab-edge design

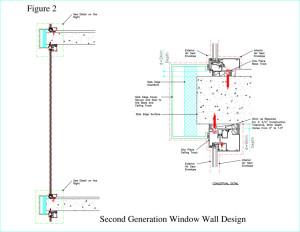

Exposed-slab-edge window walls are still used in warm regions where cost is an important factor. (In cold regions, they are also still designed, with slab edges painted with marine coatings to try to mitigate problems.) In a newer method of designing window walls (shown on the right), a decorative slab cover solves Problems 1 and 5. Further, some designs employ a ‘triple-seal-line’ design—while this improves the situation for Problem 2, it cannot completely eliminate it.

Exposed-slab-edge window walls are still used in warm regions where cost is an important factor. (In cold regions, they are also still designed, with slab edges painted with marine coatings to try to mitigate problems.) In a newer method of designing window walls (shown on the right), a decorative slab cover solves Problems 1 and 5. Further, some designs employ a ‘triple-seal-line’ design—while this improves the situation for Problem 2, it cannot completely eliminate it.

While solving Problems 1 and 5 is significant, the other issues remain. Additionally, a new, ninth challenge is created.

9. Slab-edge water condensation problem

The slab edge cover becomes the integral component of the exterior air seal envelope, resulting in the condition of the slab edge being in the interior air zone. For areas with colder climates, this means since the slab edge is closest to the exterior air, slab-edge insulation must be installed to reduce the probability of interior water condensation. However, no matter how much slab-edge insulation is used, the problem can never be absolutely eliminated.

Air-loop window walls

In the second part of this series, the author will examine how air-loop window wall assemblies can help with the nine problems. For this configuration, the design principle employs the following logic: since it is extremely difficult for a wall component to satisfy more than one design function in a durable way, each function must be isolated (i.e. the aforementioned FIC). With a singular design function, the cause of the functional problem can then be identified and possibly eliminated for good.

Raymond Ting, PhD, PE, is the president of Ting Wall Inc., an exterior wall system engineering and design company. His expertise is in the exterior wall technology and composite foam panel technology. Ting has been involved in building product/system research and development since 1969, and is the inventor of more than 30 patents worldwide. He can be reached at ting@tingwall.com.

Raymond Ting, PhD, PE, is the president of Ting Wall Inc., an exterior wall system engineering and design company. His expertise is in the exterior wall technology and composite foam panel technology. Ting has been involved in building product/system research and development since 1969, and is the inventor of more than 30 patents worldwide. He can be reached at ting@tingwall.com.