Metal and wood

Specifiers should also consider metal and wood ceilings. Metal ceilings continue to increase in popularity because of their durability and aesthetics. They are offered in a variety of finishes that can impart a very high tech or sophisticated look to a space.

Even though it is metal, this type of ceiling can provide both sound absorption and sound blocking. To achieve the acoustic benefits, the panels must be perforated and backed with an acoustic fleece. Perforations vary in size depending on aesthetic appeal, although it is possible today to have extra micro-perforated panels in which the holes are so small, they are virtually invisible.

Wood ceilings are increasing in popularity because of their beauty and the warm ambiance they impart to a space. Available in various rich, natural finishes, wood ceilings also provide access to the plenum. As with metal, perforated wood panels provide better acoustic performance than non-perforated panels.

In addition to their application in continuous ceilings, both metal and wood panels can also be used in acoustical ceiling clouds, canopies, baffles, and blades.

Other LEED credits

Acoustical ceilings can not only contribute to the new LEED credit for acoustic performance, but also to a number of other credits, including

Waste Management

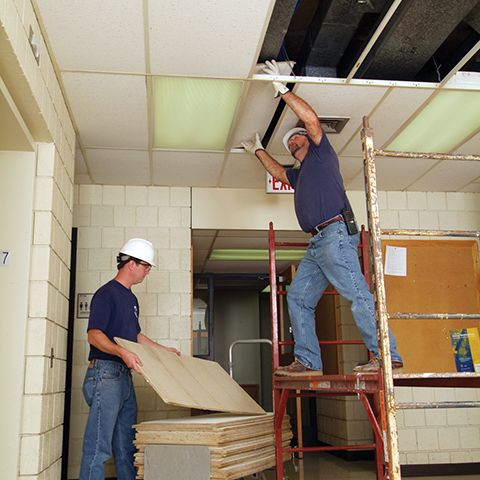

Specifiers need to be aware that when acoustical ceilings come to the end of their useful life, they can be recycled rather than dumped in a landfill. Ceiling recycling programs began in 1999. They enable building owners to ship ceilings from renovation projects to the nearest ceiling plant as an alternative to landfill disposal. The discarded ceilings are then used to manufacture new ceilings.

Ceiling panels removed from a space are either stacked on a pallet and wrapped for delivery to a ceilings plant, or dumped into a roll-off container and collected by a construction and demolition processor that will bale the tiles for delivery.

Every pound of returned ceiling panels displaces the virgin material and energy required to produce new panels, as well as the waste associated with the extraction and processing of the virgin raw materials.

The recycling of discarded ceiling panels thus has a positive impact on the sustainability of buildings while providing architectural materials that satisfy acoustical requirements within the built environment. In terms of LEED criteria, this closed-loop process can contribute to the Materials and Resources (MR) prerequisite, Construction and Demolition Waste Management, which requires development and implementation of a construction and demolition waste management plan and a final report detailing all major waste streams generated, including disposal and diversion rates.

Recycled content

Acoustical ceiling panels can also contribute to the new MR credit, Building Product Disclosure and Optimization: Sourcing of Raw Materials, Option 2: Leadership Extraction Practices. This is because mineral fiber panels can contain recycled content up to 80 percent, and fiberglass panels up to 71 percent. Wood and metal ceilings can also contribute. Wood panels contain up to 92 percent recycled content, and metal panels up to 98 percent when made from aluminum, and 25 percent when made from steel.

New ceilings panels manufactured from the discarded ceilings reclaimed as part of a ceiling recycling program contain a high level of post-consumer recycled content. These levels are particularly important in projects seeking LEED certification in which a high level of post-consumer content is desired. For the purpose of credit achievement, recycled content is determined by the sum of the post-consumer recycled content plus half of the pre-consumer recycled content. Manufacturers should be contacted for exact percentages and the pre-consumer/post-consumer breakdowns.