by Byoung-Jun (BJ) Lee, PhD, PE, SE

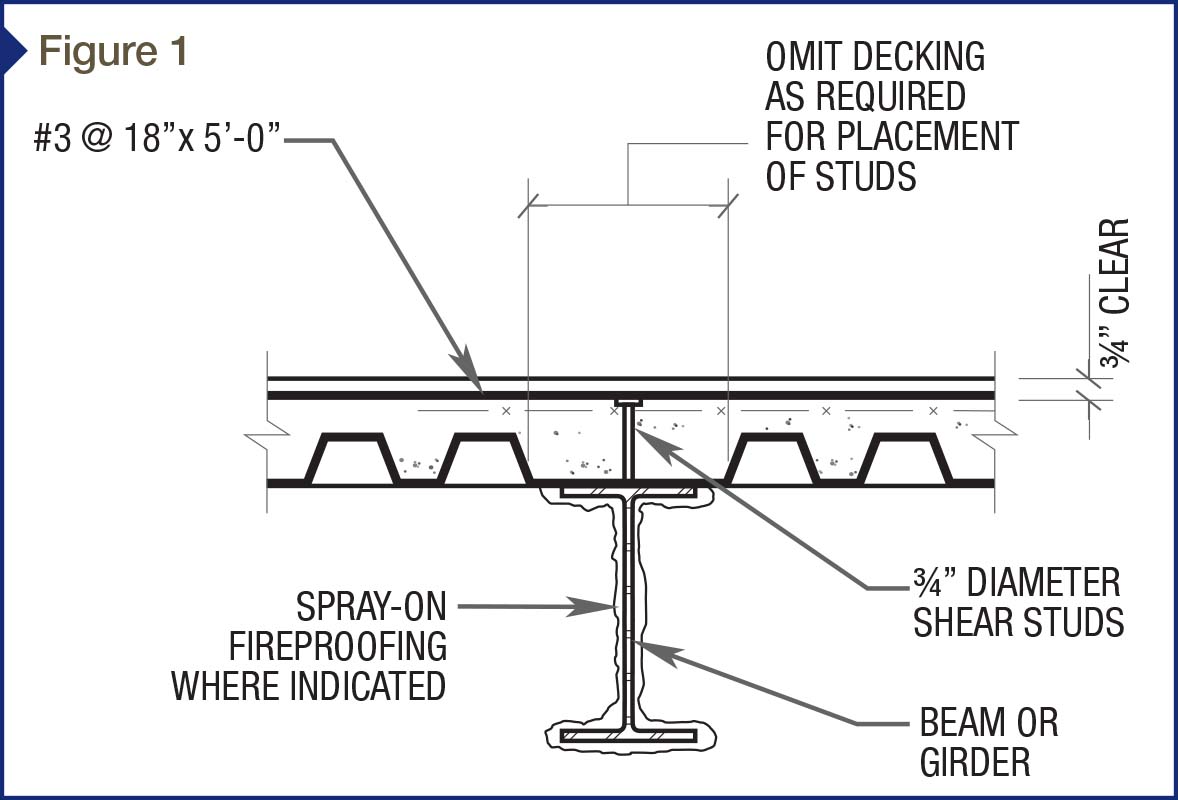

Composite steel assemblies are an efficient and popular structural option for floor construction.(See the fourth edition of Charles G. Salmon and John E. Johnson’s Steel Structures: Design and Behavior [Harper Collins College Publisher, 1996]). Figure 1 shows a typical assembly, consisting of a steel beam, metal deck, concrete slab, and shear connectors. The composite action between the steel beam and concrete provided by shear connectors creates the composite properties that make the system a very stiff and strong structural element. Used successfully for many decades, it has a proven track record in the building construction industry. (For more, see the Subcommittee on Composite Steel and Concrete Floor Systems’ article, “Construction Considerations for Composite Steel and Concrete Floor Systems,” in the September 2002 edition of the Journal of Structural Engineering [vol. 128, no. 9]).

There are two distinct types of composite slab construction: shored and unshored. In the first category, the steel beams are shored until the concrete has hardened, and the steel and concrete act as a single structural element. In unshored construction, the steel beams are not shored and designed with enough strength and stiffness in the pre-composite phase (before the concrete hardens) to support the weight of the wet concrete and any construction loads.

The majority of the issues related to finish floor elevations are related to unshored composite slab construction. Further, since its cost is typically less than shored, most structural engineers base their design on unshored construction.

Although very popular, there are many challenges and potential issues when it comes to the production of a level finished floor on unshored composite slab construction. There are ambiguous industry standards for finished floor tolerances, changes to materials and design philosophy, steel beam cambering, uncertainties in the structural behavior under construction loads, and a lack of coordination between the construction trades and members of the design team. Most of these challenges have existed for many years, and the changes to construction materials and design philosophy have further exacerbated the problem.

This article discusses the various challenges and requirements with specifying and achieving the level floor finish in the composite steel-concrete construction. The goal is to present solutions to minimize the chances of pouring a severely deflected slab, as shown Figure 2.

Industry standards for finished floor tolerances

To get a level and flat floor, one must specify the expectations. What are the benchmarks to which the contractor will be judged? This is usually where the process starts to go off-track. Specifying an acceptable tolerance is not an easy task, and may be impossible for slabs supported on structural steel using current industry standards.

Part of the issue with specifying a flat and level floor is the lack of coherent industry tolerances for this type of construction. Further complicating the matter is the combination of two distinct materials—steel and concrete—and their respective industries’ construction standards. Tolerances governing concrete construction are listed in American Concrete Institute (ACI) 117-10, Specifications for Tolerances for Concrete Construction and Materials and Commentary, and the tolerances governing steel construction are listed in the American Institute of Steel Construction (AISC) 303-10, Code of Standard Practice for Steel Buildings and Bridges.

There are three established ways to judge the acceptability of a finished floor:

- deviation from a specified elevation;

- levelness; and

- flatness.

The deviation from a specified elevation is fairly straightforward. The tolerance is given as a plus/minus value from the proposed elevation.

It is really interesting that shored and unshored composite floors use different strength and hardness in the steel beams. It makes sense that you would need a stronger material if you have to support the weight of wet cement. The diagram was really helpful, it made it much easier to follow along with your descriptions. Thanks for the info about composite floors.

You really covered a lot of great points here. Thanks so much for sharing all of this information!