Image courtesy Linetec

There is no escaping the presence of bacteria. The majority of the bacteria that are encountered benefit the environment by helping return nutrients to the soil through decomposition of organic waste, or helpful to the human body (probiotics) through the digestion of food. In contrast, some bacteria cause stains, odors, and product and coating surface deterioration as their metabolisms produce acidic materials and sulfur-based compounds. These bacteria can adversely affect every day surfaces.

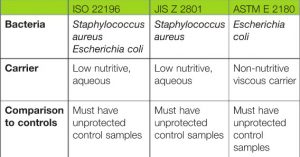

Most bacterial test protocols require the testing of two organisms, one Gram-positive and the other Gram-negative, due to the differences in the cell wall structure. Some antimicrobials are more effective against one or the other of these groups. Other types are broad-spectrum with good efficacy measured against both.

Fungus

Early fossil records suggest fungi have been on Earth for more than 550 million years. Some experts estimate more than 1.5 million fungus species exist today. Common fungi include mushrooms, puffballs, truffles, yeasts, and most mildews.

Unlike bacteria, fungi are multi-cellular organisms containing membrane-bound organelles, and a ‘true nucleus.’ Fungal cells are encompassed by a strong, but flexible, nitrogen-containing polysaccharide called “chitin.” The chitin protects the fungus and, depending on the mode of action, can reduce or eliminate the effectiveness of many antimicrobials.

The most common means of fungal reproduction is the formation of spores. The spore formation occurs in fungi, such as Aspergillus niger (black shower mold), Penicillium pinophilum (bread mold), and Trichophyton mentagrophytes (Athlete’s Foot).

Image © Stockvault. Image courtesy Linetec

Mold spores are present everywhere in both indoor and outdoor environments, and many of the products found in buildings provide rich nutrient sources. The most common defense is prevention. This can include controlling the moisture in a building in order to avoid high humidity levels, and specifying products with antimicrobial protection to resist mold growth.

Finish functionality

An antimicrobial agent in a coating is designed to inhibit the growth of stain- and odor-causing bacteria and to help prevent product deterioration of the coating from mold and mildew. The agent neither replaces normal cleaning practices nor is intended to protect users from disease-causing microorganisms. Microbes landing on surfaces treated with silver-ion antimicrobial coatings are not killed; rather, the silver-based particles emit ions that interfere with the microorganism’s metabolism, reducing its ability to reproduce.

Coupled with regularly scheduled cleanings, the antimicrobial coatings create an inhospitable environment for microbial growth by damaging the microbes’ cell walls. Additionally, this interferes with the conversion of nutrients into energy, inhibiting reproduction. The microbes die and are not replaced within the population.

Antimicrobial treatments in solid products are largely surface treatment effects. For most, efficacy is related to controlled diffusion at the surface. Limited or no migration out of the surface provides durability as the incorporated active ingredient is not used up.

The benefits of antimicrobial coatings on surfaces include odor control, and reduced staining and surface discoloration from bacteria, mold, and mildew. Again, please note products and surfaces treated with antimicrobial coatings do not disinfect their surroundings or contents. For example, neither is the water in a treated cup sterilized nor is growth in the water inhibited.

Stringent specification

An antimicrobial coating technology can provide an added level of protection for the coated surface. Through research and testing, a high-performance architectural coating system containing silver-ion antimicrobial protection has been developed for use on both interior and exterior aluminum surfaces of architectural products to inhibit the growth of stain- and odor-causing bacteria. This architectural liquid coating uses a 70-percent polyvinylidene fluoride (PVDF) resin-based system.

When moisture is present, the antimicrobial technology in the PVDF coating activates the ion exchange mechanism and small amounts of silver cations (positively charged ions) are released into aqueous environments. The release rate is regulated by the unique amorphous glass structure, giving extraordinary longevity. The released silver acts on stain- and odor-causing bacteria by disrupting their metabolism and reproduction.