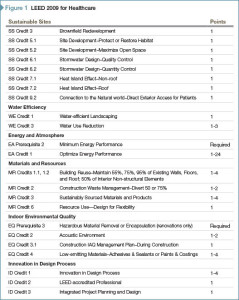

In comparison to LEED for New Construction (LEED-NC), LEED for Healthcare modifies existing credits and features new, healthcare-specific ones. In all, six prerequisites and 25 credits were modified, and three prerequisites and 15 credits were added to the rating system. The minimum program requirements for LEED-NC also apply to LEED-HC projects. For structural elements and pavements, concrete containing SCMs contributes to LEED credits in several categories. (Figure 1, lists the specific names.)

Following the official launch of LEED-HC, projects meeting certain criteria (i.e. hospitals, long-term care facilities, and other buildings serving individuals seeking medical treatment) must use the healthcare program rather than LEED-NC. Buildings with other medically related uses, such as medical education and research centers, may use LEED-HC at the project team’s discretion.

Sustainable Sites (SS)

In this category, concrete and blended cements using SCMs contribute to points gained by:

- in-situ soil stabilization with soil cements in brownfield redevelopment;

- reduced footprints and limited site disturbance with above and below ground multi-story concrete structures;

- pervious concrete and permeable grids for stormwater management; and

- lighter-colored, high-albedo concrete pavements in landscape and exterior systems or roof systems with concrete tiles that reduce the urban heat island effect.

Energy and Atmosphere (EA)

Buildings constructed using concrete possess thermal mass, which helps moderate indoor temperature extremes and reduce peak heating and cooling loads. This improves energy performance in structures.

Light-colored concrete materials can be produced using SCMs to reduce lighting energy costs. Reflective surfaces help reduce the amount of fixtures and lighting required. Additional benefits with concrete envelope systems include:

- thermal mass and acoustical properties;

- pest resistance; and

- increased resistance to natural disasters, including earthquakes, hurricanes, floods, and fire.

Materials and Resources (MR)

SCMs can extend a structure’s useful service life because they improve concrete durability. Well-constructed concrete walls, floors, and roofing elements containing these supplementary materials can be left in place when the building is refurbished, its interior renovated, or its function changed. The purpose of the reuse credit is to extend the life of the existing building stock, conserving resources and reducing waste and the environmental impact of new construction.

Concrete-producers recycle returned concrete, aggregate, and wash water during the construction process, which can contribute to construction waste management credits. Additionally, crushing and recycling of concrete waste materials into clean fill or road base applications diverts usable resources from landfills.

Recycled content credits are easily obtained with blended cements and SCM use in concrete. Concretes containing multiple SCMs can contribute to more LEED credits because the percentage of virgin material replaced by recycled content determines points. Moreover, SCMs extend concrete service life through improved durability, further reducing impact on landfills and lessening the economic burden of construction.

Cement manufacturers often replace fossil fuels with recycled materials; many also include post-industrial recycled content materials to replace conventional materials for manufacturing portland cement. This may contribute to achievement of this credit by reducing the demand for virgin materials, materials sent to landfills, and energy required in cement manufacture.

Indigenous resources used to manufacture cement and concrete, including SCMs, are usually obtained or regionally extracted within 800 km (500 mi) of the project site, reducing the environmental impact of transportation. Projects with large amounts of concrete can typically achieve both regional materials credits.

Indoor Environmental Quality (EQ)

Concrete building materials contain low to negligible levels of volatile organic compounds (VOCs) that degrade IAQ when they off-gas from new products, such as interior finishes, carpeting, and furniture. Additionally, VOCs combine with other chemicals in the air to form ground-level ozone. As concrete building materials serve as a structural and finish material in wall and floor applications, they reduce the need for applied finishes or flooring materials and contribute to a healthier indoor environment.

Concrete-based building envelopes offer significant long-term economic advantages and provide quieter, more comfortable, safer, and environmentally considerate structures. Unbroken exterior envelopes offer air and moisture barriers, preventing mold growth and providing fewer cold spots and drafts offering thermal comfort to occupants. Thermal mass affects temperature perceived by the occupants through radiance rather than air temperature.

Finally, concrete can help a structure admit more daylight deeper into a building that can be used to facilitate daylighting strategies. Higher strength concretes can minimize beam depths and maximize daylight and views through windows. An interior concrete core can be designed to accommodate higher structural loads and shear forces, allowing fewer obstructions along the building perimeter. Post-tensioning can be used to obtain longer spans, minimizing the number of columns obstructing views.

Innovation and Design (ID)

Concrete building materials containing SCMs provide incentives going beyond LEED requirements and create innovative strategies not specifically addressed in the rating system. Several potential credits have been identified that relate to exemplary performance of concrete building materials containing SCMs. Three examples are:

- decreased lifecycle environmental impact, due to concrete’s low embodied energy and long life, durability, and low maintenance needs;

- IAQ improvements thanks to eliminating the need to paint or adhere finishes by choosing either architectural or prefaced concrete building systems;

- high percentage of SCM use in comparison to the usual modest percentages of fly ash, slag cement, or silica fume.