Specifying glass for sloped glazing and skylights

by sadia_badhon | August 3, 2020 8:12 am

by Glenn Ferris

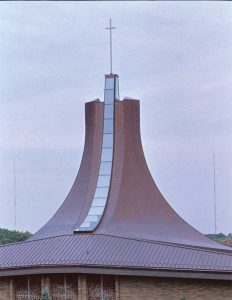

[1]

[1]Given the growing use of large and complex sloped glazing systems—considered to be installations where the glass is inclined 15 degrees or more from vertical—as creative architectural statements, the design criteria for them are rapidly evolving. The codes governing their application are also changing to ensure their performance as a viable element of the building envelope. The most important design considerations are environmentally imposed loads, and minimizing their tendency to cause breakage, which can have a greater impact on life and property than it does with vertical glazing.

The International Building Code (IBC) refers to loads on sloped glass in Section 2404.2 for wind, snow, seismic, and dead loads. Section 2405, devoted to sloped glazing and skylights, covers factors such as allowable glazing materials, framing, and skylight performance grades.

Allowable types of glazing are:

- laminated glass with a minimum of 0.75 mm (30 mils) polyvinyl butyral (PVB) or equivalent interlayer;

- fully tempered glass;

- heat-strengthened glass;

- wired glass; and

- approved plastics.

Potential breakage is key

Proper glass selection and system design is intended to meet specified design load(s) with the primary goal of reducing the probability of glass breakage, which poses risks to people and property. The differences in design considerations between vertical and sloped glazing must be taken into account. For example, sloped glazing is more susceptible to impact from falling objects and hail, and is also more likely to fall from its opening when it breaks than vertical glazing. Breakage may occur due to several factors, either acting alone or in combination.

[2]

[2]Photo courtesy CrystaLite

For safety in case of breakage, the latest version of IBC requires the use of screens below sloped glazing positioned more than 30 degrees from vertical and 3 m (10 ft) above a walking surface, except when the glazing is laminated glass with an interlayer of 0.75 mm or greater in thickness.

Design considerations

Good design focuses on the choice of glass, selected for a low probability of breakage, yet with minimal consequences if breakage does occur. Designers and architects of sloped glazing edifices must orchestrate the use of industry and regulatory standards and guidelines, such as ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings, the American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7, Minimum Design Loads for Buildings and Other Structures, and the American Architectural Manufacturers Association (AAMA) GDSG-1, Glass Design Guide for Sloped Glazing and Skylights, as well as IBC and the International Residential Code (IRC).

The prediction of the performance of glass in sloped glazing is more complex than for vertical glazing, given that snow loads must be considered, and different thicknesses and irregular shapes of glass lites may be used. The considerations involved are numerous.

Strength

The apparent strength of the glass—and in the case of laminated glass, the ability of the interlayer material to resist stresses—is time dependent. Short-term loads, such as wind, must be considered differently than long-term ones like snow and dead loads. There are two primary load types to consider: dead and live.

Dead load

For sloped glazing systems, the weight of the glass is the primary dead load. Any loads transferred to the glass due to twisting or other deformations of the framing also are considered dead loads.

One 1 m2 of glass that is 1-mm thick weighs roughly 2.5 kg (1 sf of glass 1-in. thick weighs roughly 13 lb.). The equivalent uniform dead load of a given type of glass in kilograms may be estimated by multiplying the total glass thickness in millimeters by 2.5 (or, the dead load in pounds if the thickness is in inches and is multiplied by 13). This will give the dead load for horizontal glass. For other slopes, the value should be multiplied by the cosine of the angle of slope in degrees as measured from horizontal (pitch).

[3]

[3]Photos courtesy Wasco

For example, a 12.7-mm (1/2-in.) thick horizontal glass sheet would have a dead load of 31.75 (12.7 x 2.5) kg/m2 (or, a 1/2-in. thick horizontal glass would have a dead load of 6.5 [0.5 x 13] lb/sf). When installed in a sloped glazing system at a 45-degree pitch, the dead load is 31.75 cos 45 (31.75 x 0.707), or 22.4 kg/m2. The equivalent in imperial units for a ½-in. thick glass sheet at a 45-degree pitch is 6.5 cos 45 (6.5 x 0.707) or 4.6 lb/sf.

Live load

Live loads are unattached loads imposed by window washing devices, dropped or temporarily placed equipment or supplies, or a person walking on the glass. Codes require the framing members supporting glass to withstand concentrated live loads, but this does not extend to the glazing itself. In fact, glass should not be exposed to live loads. Therefore, live loads are not considered in the design of glass meant for skylights or sloped glazing.

ASTM E1300 considers the combination of snow and wind loads and glass slope and weight. The standard covers all conditions for different edge support methods. It approaches glass strength statistically, as microscopic variations from one sheet of glass to another preclude accurately predicting the strength of a given lite. For example, it supplies load resistance charts for a glass probability of breakage of eight lites per 1000, which is considered reasonable for most applications.

The strength of heat-strengthened and fully tempered glasses is taken into account in ASTM E1300 through the use of a glass type factor (GTF). Essentially, the appropriate GTF multiplied by load resistance of annealed glass gives the load resistance for a specific thickness of other types of glass. When using ASTM E1300 for insulating glass, a load share (LS) is applied to each of the glass lites in order to determine the load resistance of each lite in an insulating glass unit (IGU).

Wind load

The magnitude of wind loads is based on slope, orientation with respect to the wind, effect of surrounding structures and terrain, and wind velocity.

[4]

[4]Photo courtesy Vtech Skylights

For common building shapes, background guidance on design wind velocities is found in ASCE/SEI 7, which gives the peak wind velocity that can be expected in a specific geographical location based on a mean recurrence interval of 50 years of a maximum wind gust of three seconds’ duration. One caveat: buildings of unusual shape or geometry may render the standard inadequate for defining loads on sloped glazing and skylights.

For potential exposure to hurricane-force winds, it is best to refer to Chapters 16 and 24 of the Florida Building Code (FBC) for appropriate measures. Those outside Florida may consult ASTM E1996-17, Standard Specification for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Windborne Debris in Hurricanes.

Snow load

While wind and snow loads are a type of live load, they are considered separately in load analysis and are sometimes termed environmental loads. A common error is to specify snow loads (long duration) as live loads (short duration). This could lead to the under-design of a sloped glazing system. Also, these loads may be dramatically increased beyond the normal snowpack due to drifting.

Surface damage

Flat glass surfaces inherently have numerous randomly distributed microscopic flaws, resulting in widely varying strengths among otherwise identical lites. This may be accommodated in various ways, one of which is the coefficient of variation—a measure of the distribution of the glass strength for a large number of lites. It is influenced by the degree of heat treatment of the glass, being highest (0.25) for annealed, 0.15 for heat-strengthened, and lowest for fully tempered (0.10). This reflects the increase in glass strength due to higher surface compression. In practical terms, a coefficient of variation of 0.25 means the strength of 68 percent of the glass lites will be within ±25 percent of the average and 95 percent within ±50 percent of the average.

Impact from wind-borne debris

The ability of fenestration of all types to resist such impacts is especially important in areas where high wind events, such as hurricanes, regularly occur. Fenestration materials in these areas should either be rated as impact resistant and/or be protected by impact-protective systems. ASTM E1886, Standard Test Method for Performance of Exterior Windows, Curtain Walls, Doors, and Impact Protective Systems Impacted by Missile(s) and Exposed to Cyclic Pressure Differentials, and E1996 commonly are referenced testing specifications. For Florida’s High Velocity Hurricane Zone (HVHZ), Miami Dade County testing protocols TAS 201, Large and Small Missile Test Standards, TAS 202, Uniform Structural Load Standards, and TAS 203, Uniform Cyclic Pressure Test Standards, are specified.

[5]

[5]Photos courtesy Wasco

To minimize the possibility of penetration, it is recommended a single lite, or the inboard lite of insulating glass be laminated with an interlayer thickness of 1.5 mm (60 mils) or more. In regions where hail is common, the use of laminated glass with both plies of heat-strengthened or fully tempered glass is recommended. Here, Factory Mutual (FM) 4431, Approval Standard for Skylights, is often the governing standard.

Thermal stress

Differential thermal expansion between framing and glazing, as well as between exposed and shaded areas of a given lite, must be accommodated through appropriate glass bite dimensions and selection of proper sealant and glass type. For most orientations, the temperature sloped glazing may reach is usually higher than for vertical glazing because the sun’s radiation would be more perpendicular to the glass surface and layering of warmer air at the interior. Consequently, such thermal stresses require heat-strengthened or fully tempered glass.

Frame deflection limits

A supported glass edge should have an edge deflection limited by the framing member to no greater than L/175 where L is the length of the glass edge and the deflection is determined by the displacement of the framing member along the edge.

In general, the preferred practice for glazing in skylights and sloped glazing is to provide firm support for all edges of the glass. This is mandatory for IGUs. The support may be by conventional channel glazing or by structural retention with a silicone sealant.

[6]

[6]Water drainage

Water infiltration and condensation should be drained or weeped away from the edges of the glass to prevent detrimental freezing of the water, damaging effects of moisture on edge seals of insulating glass, or possible debonding of interlayer material in laminated glass. The framing system must always drain the water from the lowest points of the glazing channel and framing system. Assemblies that work well for vertical glazing are often unsatisfactory for sloped glazing.

Size limitations

While large, open expanses of glass that are uninterrupted by framing may be aesthetically desirable, experience suggests limitations must be placed on the use of certain types and thicknesses of glass in sloped glazing beyond those required by building codes.

For example, annealed laminated glass is recommended to be limited to maximum areas depending on glass thickness. For two plies of 3-mm (1/8-in.) glass, the maximum size should be 1.1 m2 (12 sf); for two plies of 5-mm (3/16-in.) glass, 1.7 m2 (18 sf); and for two plies of 6-mm (1/4-in.) glass, 2.2 m2 (24 sf). Larger maximum areas are permitted for heat-strengthened or fully tempered laminated glass, amounting to roughly twice that of annealed laminated. The thickness of the interlayer may be 0.75 mm when annealed glass plies are used. When plies are heat-strengthened or fully tempered glass, the interlayer thickness should double. For insulating glass, the maximum dimensions are dictated by the maximum allowable sizes of the two lites of glass, which is generally specified by the manufacturer.

Applying design considerations such as these is more important now than ever, given the increasing recognition of skylights and sloped glazing systems as energy-saving ‘green’ options, especially when properly applied and melded with smart controls of electric lighting to maintain a stable interior level of illumination. Current codes and design conventions aimed at implementing them enable conformance with green building rating systems such as Leadership in Energy and Environmental Design (LEED) or GreenGlobes while ensuring installations are safe and durable, as well as energy efficient.

All of these design considerations and more, as well as guidance in applying them, are provided within AAMA GDSG-1, published by the Fenestration and Glass Industry Alliance (FGIA). Other published resources include:

- AAMA SDGS-1, Structural Design Guidelines for Aluminum Framed Skylights;

- AAMA TIR-A7, Sloped Glazing Guidelines;

- AAMA TIR-A11, Maximum Allowable Deflection of Framing Systems for Building Cladding Components at Design Wind Loads; and

- the Insulating Glass Manufacturers Association (IGMA) TB-3001, Guidelines for Sloped Glazing.

For more information, visit www.fgiaonline.org[7].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/1ConstructedRoofSkylight-FGIA.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/2CurbedSkylight–CrystaLite.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/4SchoolCafeteria–Wasco.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/7MoistureControl–VtechSkylights.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/5UnusualSkylight_interior–Wasco.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/8WindAndSnowLoads–Wasco.jpg

- www.fgiaonline.org: http://www.fgiaonline.org

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2020/07/FGIA_GlennFerris.jpg

- gferris@fgiaonline.org: mailto:gferris@fgiaonline.org

Source URL: https://www.constructionspecifier.com/specifying-glass-for-sloped-glazing-and-skylights/

[8]Glenn Ferris is the Fenestration and Glass Industry Alliance’s (FGIA’s) fenestration standards specialist. He began his career with the association in 2018. He has extensive experience in the fenestration industry dating back to 1992. Ferris is a liaison for many councils, committees, and study/work/task groups guiding them in the completion of the scope of each group. He can be reached at gferris@fgiaonline.org[9].

[8]Glenn Ferris is the Fenestration and Glass Industry Alliance’s (FGIA’s) fenestration standards specialist. He began his career with the association in 2018. He has extensive experience in the fenestration industry dating back to 1992. Ferris is a liaison for many councils, committees, and study/work/task groups guiding them in the completion of the scope of each group. He can be reached at gferris@fgiaonline.org[9].