UL has advanced its position on discouraging the use of extrapolated data in recent history, publishing stronger language against the practice. In its 2014 “The Fire & Security Authority” publication and its category code number publications—BXUV and CDWZ—that provide guidance for 263-compliant fire-resistance ratings compliant with ANSI/UL 263, UL said the average thickness of an intumescent coating “should not exceed the maximum thickness published in the individual [steel section] designs.” In 2017, UL published the following fire-resistance guideline as part of the ANSI/UL 263 BXUV guide emphasizing the need to avoid extrapolating data:

Extrapolation of member size and/or material thickness shown in the individual designs has not been investigated and would be considered to void the existing certified assembly.

Finally, in its strongest language yet, UL stated the following as part of its “Best Practice Guide for Passive Fire Protection for Structural Steelwork,” published in October 2018:

Extrapolated thicknesses that are beyond the scope of the published UL design without additional supporting test data are not considered acceptable. Additionally, extrapolated material thicknesses that are beyond the published UL design are not recognized by UL and are considered outside the scope of the UL Certification.

When engineers or architects find data is unavailable for a steel section, they have two options:

- consider an alternate steel size or profile; or

- use advanced structural engineering design principles from the American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7-16, Minimum Design Loads For Buildings and Other Structures, Appendix E guidelines.

This article only focuses on specifying different steel sections as the ASCE/SEI guidelines—that consider the steel strength supporting the structure and the reserve strength available to resist fire—deserve a stand-alone article.

Understanding steel section data

UL publishes a variety of categories for rating the fire resistance of steel sections, with each one having different test and pass criteria. Additionally, UL’s coating DFT requirements differ for various steel member shapes and orientations. Due to both factors, it may be unsafe to use the published maximum intumescent coating thickness in one UL category for another listing.

Each steel type (e.g. beam, column, or brace) listed in UL’s database has a ‘section factor’ to help determine the required intumescent coating DFT for meeting various fire-resistance ratings. This value is a ratio that differs depending on the style of the steel section as well as its exposure to fire. The section factor ratio W/D covers I-beam (or W-profile) sections, while the ratio A/P represents hollow structural sections (HSS) such as cylindrical (pipe) columns. The variables refer to:

- W: The weight of the section (in pounds/foot);

- A: The cross-sectional area of all sides of the HSS (in inches); and

- D and P: The heated perimeter of the section (in inches) or the total square area that would be in contact with fire.

See Figure 3 for an example of a fully exposed W-profile. Here, D represents the section’s entire surface area because it would all be in contact with direct heat from a fire. However, in Figure 4, D only includes the surface area of the steel that is not in contact with the concrete ceiling/slab above the beam. The ceiling—or any material in contact with or partially encasing a steel section—serves as a heat sink in a fire, taking heat away from the coated steel section and offering some fire resistance. In Figure 5, A is the entire surface area of an HSS section, minus any areas in contact with heat sinks.

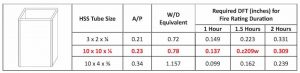

The W/D and A/P ratios represent how quickly a steel section will heat up in a fire. One can calculate these ratios by dividing the weight (W) or area (A) by the heated perimeter (D or P). The A/P ratio can then be converted into a W/D ratio to directly compare W-profile and HSS sections.

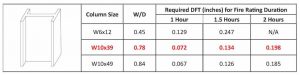

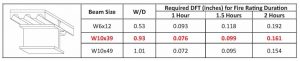

The amount of fire protection (intumescent coating DFT) required for a steel section is inversely proportional to its section factor ratio. A larger ratio indicates less fire protection is required, and a smaller one requires the application of thicker fire protection. The examples shown in Figures 3, 4, and 5 reveal the smaller W/D and A/P ratios at the top require a greater coating DFT. They also demonstrate coating DFT requirements increase with longer fire rating durations.

It is helpful to make some direct comparisons to understand why it is impossible to use W/D and DFT data from one UL category listing to the next even when the steel section is of the same size.

In Figure 4, the required intumescent coating thickness for a two-hour fire rating for the W10x39 Beam N section is 4 mm (161 mils) DFT (marked in red). When looking at the same-sized W10x39 Column Y section in Figure 3 (marked in red), one will find a smaller W/D ratio that equates to the higher DFT requirement of 5 mm (198 mils) for the same two-hour rating. The Column Y section DFT is 23 percent greater than the Beam N requirement, even though the two sections are of the same size. This difference is because Beam N is in contact with concrete on one face, making its heated perimeter much smaller.

Further, the coating DFT requirements are drastically different for HSS columns requiring significantly higher intumescent coating DFTs because of their structural profile. In Figure 5, the A/P ratio has been converted to W/D for simpler comparison. The 10 x 10 x ¼ HSS Column Y has the same column section factor and a similar size to the W10x39 Column Y in Figure 3 (see red text for both). Both sections are 250 mm (10 in.) deep and have a similar weight per foot. Yet, the HSS Column Y section requires an 8-mm (309-mils) DFT for a two-hour fire rating. This value is 92 and 56 percent greater than the W10x39 Beam N and Column Y DFT requirements, respectively.

Why extrapolated data does not add up

The data limitations on the lower and upper ends of steel member sizes listed in ANSI/UL 263 and ASTM E119 are a result of UL either not testing such steel sections or determining they are unable to be protected with intumescent coatings. As mentioned, extrapolating data beyond the published limits could result in specifying an intumescent coating DFT that is either too low or high, both could result in insufficient fire protection. However, UL has offered some flexibility in specifying coating thicknesses for steel sections in between the established lower and upper size limits.