Specifying seismic ceiling safety

by Katie Daniel | December 29, 2015 11:00 am

[1]

[1]by Mark Taylor

The International Building Code (IBC) sets minimum requirements for life safety and preservation of property. All 50 states and the U.S. Virgin Islands use the code at local or statewide levels. Following its requirements helps increase safety and may decrease possible long-term liability costs. Properly specified and installed in commercial buildings, ceiling suspension systems with acoustic panels can meet current codes and seismic performance requirements across the United States.

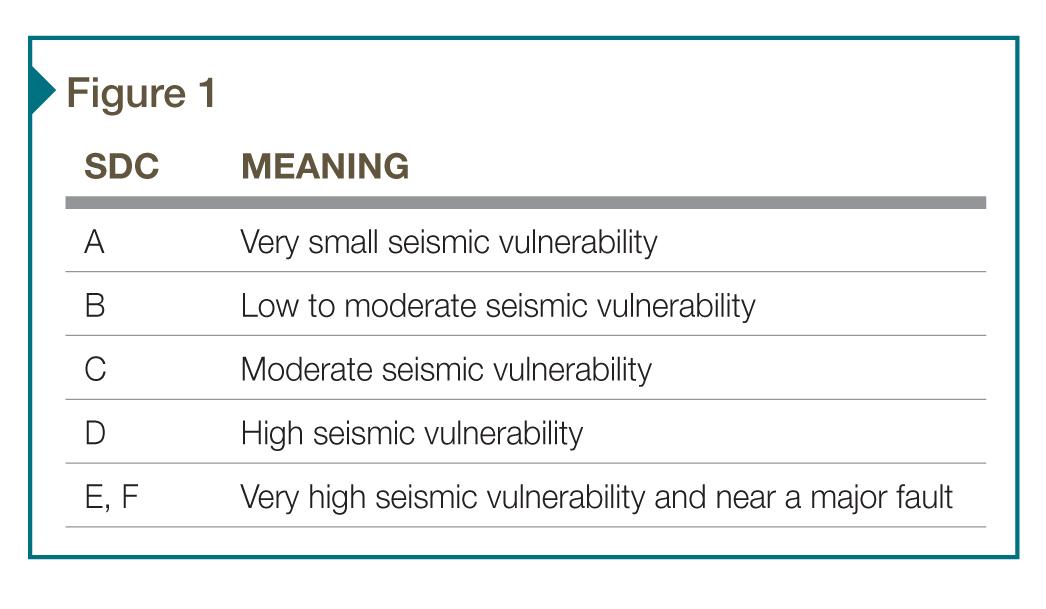

According to the 2012 IBC, a Seismic Design Category (SDC) must be established for each construction project based on anticipated ground motion, the type of soil in a specific geographic area, and the occupancy category. These SDCs determine specific product performance and installation methods required by code to withstand certain seismic activity levels.

A professional engineer or a registered architect must specify the SDC on the project drawings. Structural engineers ultimately have responsibility for building elements and systems that carry the structure’s loads. However, these components only represent 25 percent of a typical commercial building’s inventory. The remaining 75 percent are non-structural components—such as is the case for suspended ceiling systems—where responsibilities are assigned to multiple team members.

Industry standard construction

Ceilings are important non-structural components vulnerable to earthquake damage, even in well-designed buildings. Suspended, acoustic panel ceilings have been the preferred design choice in commercial buildings since the 1950s. The interconnected ceiling systems typically consist of a metal grid comprising cross-tees and main runners.

The main runners are suspended by hanger wires from the structure above, and wall channels or angles provide a clean look around the perimeter. Lay-in and snap-up ceiling panels, such as stone wool acoustic ceiling tiles, are used to conceal the visible structure, pipes, wires, HVAC equipment, and suspension system.

For frequently accessed plenum areas, ceiling suspension systems with snap-up torsion spring panels allow maintenance staff access without completely removing the panel. The connection’s strength to the suspension system enables torsion spring panels to be effective in areas concerned with seismic activity.

During a seismic event, damage can occur at the perimeter when the vibration period of ceiling systems significantly differs from the surrounding building structure and other nonstructural components, such as non-load-bearing partition walls. This can compromise structural integrity at the perimeter, increasing ceiling motion and also potentially leading to total failure of the ceiling system. Ceilings with heavy lighting fixtures may be susceptible to damage around the fixtures, causing light fixtures to fall into the occupied spaces. The consequences may include damaged property, blocked egress, and life-safety hazards.

[2]

[2]Intended to minimize risk and damage, installation standards for ceiling suspension systems in SDCs are specified to ensure:

- ceiling suspension systems are strong enough to resist lateral force imposed upon them without failing; and

- border panels are prevented from falling from the ceiling plane.

ASTM E580/E580M, Standard Practice for Installation of Ceiling Suspension Systems for Acoustical Tile and Lay-in Panels in Areas Subject to Earthquake Ground Motions, covers acoustical ceiling suspension systems and their additional requirements for SDC C, D, E, and F as outlined in IBC 2012 (Figure 1). Local authorities having jurisdiction (AHJs) determine the application of these practices often using project specifications and detailed information from ceiling manufacturers and industry associations.

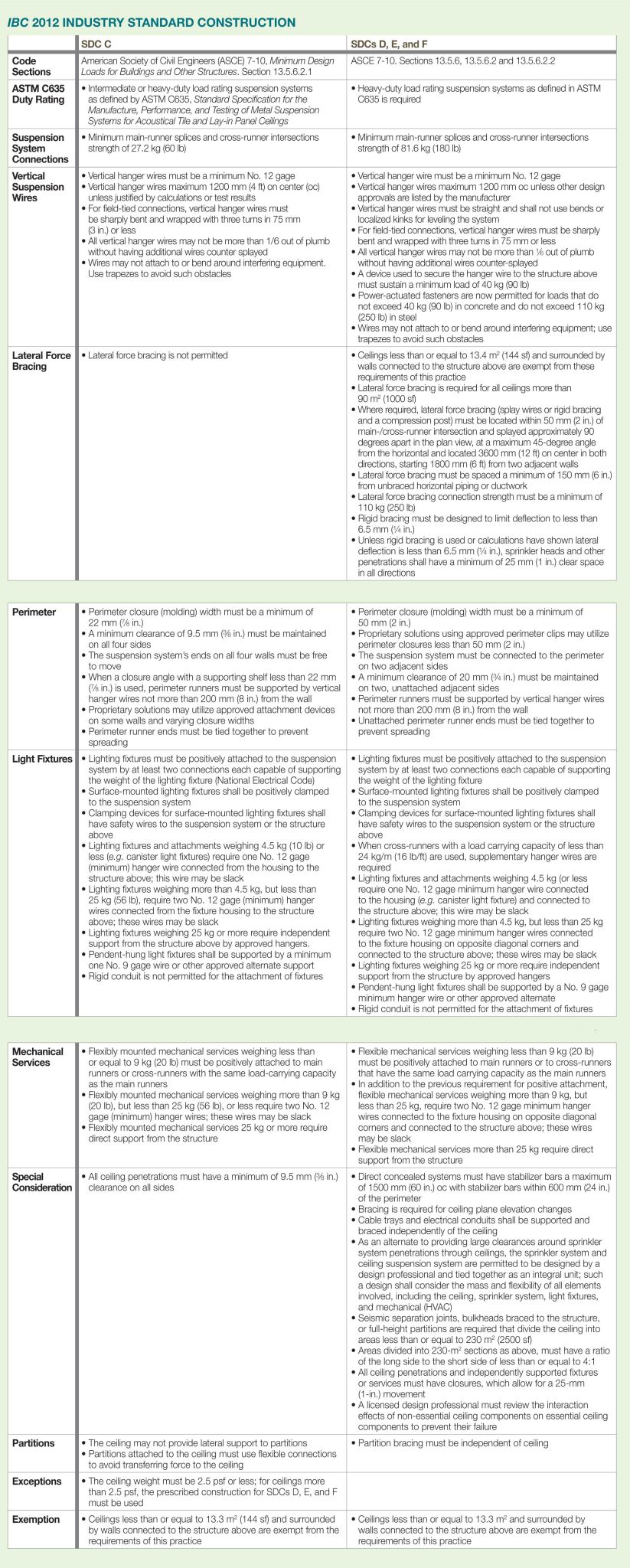

The 2014 Ceilings & Interior Systems Construction Association (CISCA) Seismic Construction Handbook[3] summarizes industry standard construction per the 2012 IBC for acoustical ceiling suspension systems. The chart in “IBC 2012 Industry Standard Construction” references the CISCA handbook and shows the substantial differences for SDC C and SDCs D, E, and F with respect to the significance of a particular project’s seismic vulnerability.

[4]

[4]

[5]

[5]Installation and inspection

As noted in the chart, most ceiling systems are offered in ‘intermediate-duty’ and ‘heavy-duty’ performance per ASTM C635, Standard Specification for the Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings, to satisfy the requirements of all seismic code constructions. The exposed tee construction permits direct upward access to mechanical systems and is a cost-effective solution to seismic requirements. Stab-in cross-tees cantilever during installation and will not fall out, making not only for an easier installation, but also protecting against lateral pull-out.

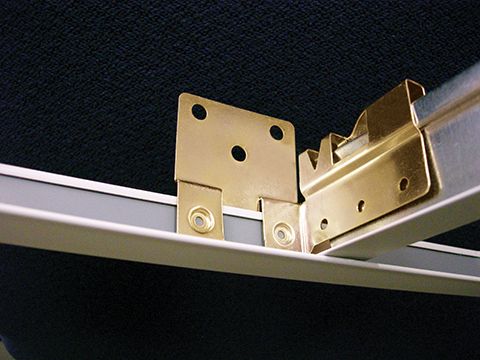

Current code requirements include a 50-mm (2-in.) wide perimeter wall molding, and stabilizer bars to provide support, and prevent the ceiling grid from spreading apart along the molding. Some ceiling manufacturers offer a seismic perimeter clip as an alternate method of stabilizing tees at the perimeter. This allows installing contractors to use a 24-mm (15⁄16-in.) angle in lieu of the 50-mm (2-in.) angle and eliminates costly stabilizer bars. Supporting timesaving, error-free installation, at least one manufacturer provides the seismic perimeter clip with pre-drilled screw holes and in a bright gold to make it easily identifiable on jobsite inspections.

While IBC establishes the requirements, it is the code official that has the power to enforce its provisions. Code officials also have the latitude to allow materials and methods of construction not addressed in the code. In this case, they can perform their own analysis of the evidence presented or they can rely on independent, qualified sources such as International Code Council-Evaluation Services (ICC-ES) to do the analysis and provide their findings. The ICC-ES resulting report is specific, technical evidence on which the code official can base approval of a particular design without delaying construction.

[6]

[6]As ceiling panel performance and non-tee bar suspension systems are not well-defined in the IBC requirements, ceiling system manufacturers and structural engineering firms have worked together to test both standard and non-standard ceiling systems for seismic performance at the Structural Engineering Earthquake Simulation Laboratory (SEESL) at the State University of New York (SUNY) at Buffalo. The results of these full-scale seismic tests offer proven safety and performance support for standard and non-standard ceilings, flexible design options, and more efficient installation designs.

Properly specified and installed, ceiling suspension systems with acoustic panels can meet current codes and seismic performance requirements in all SDCs and all U.S. jurisdictions. When engineered to reduce installation time, ceiling suspension systems not only support life safety and the property preservation during an earthquake, but they also can save associated material and labor costs. Combined with the inherent properties of stone wool acoustic ceiling panels, these systems also protect people from noise and the spread of fire, while making a constructive contribution toward a sustainable future. For more information on stone wool ceiling assemblies, click here.[7]

Mark Taylor is the marketing manager for Rockfon’s ceiling systems for North America. He began his career in the commercial building industry as a carpenter; in addition to field experience, he earned a bachelor’s degree in industrial technology from Eastern Illinois University. Continuing to grow and share his industry knowledge, Taylor is a member of the Ceilings & Interior Systems Construction Association (CISCA) and recently published Rockfon’s new brochure titled, “Seismic Relief.” He can be reached at mtaylor@rockfon.com[8].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/ROCKFON_AR_ASU-HSS_Pebble3603.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/Figure-1_seismic.jpg

- Seismic Construction Handbook: http://www.cisca.org/i4a/ams/amsstore/itemview.cfm?ID=274

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/seismic-Image.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/ROCKFON_AR_ASU-HSS_Pebble3613.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/ROCKFON_SS-1496SeismicPerimeterClip.jpg

- here.: http://www.constructionspecifier.com/designing-stone-wool-ceiling-assemblies

- mtaylor@rockfon.com: mailto:mtaylor@rockfon.com

Source URL: https://www.constructionspecifier.com/specifying-seismic-ceiling-safety/