Devices utilizing air-dried paints to match the roof color are easy initially, but may produce a poor outcome after weathering a few years. This is due to inferior characteristics of air-dried paints when compared to factory-applied finishes of metal panels. Powder coating may provide greater longevity in terms of color stability, but generally is not as durable as factory-applied polyvinylidene fluoride (PVDF) panel finishes.

Snow retention techniques

There are three techniques for mounting snow retention systems to a metal roof. Two utilize mechanically attached snow guards. The distinction between the two involves clamping, which grips the standing seam in some fashion without actually puncturing the panel material (non-penetrating) versus fastening screws through the roof material (penetrating) into the structure. The third method uses a chemically attached, ‘peel-and-stick’ adhesive tape or pumpable glue. This is often used for individual, discontinuous (cleat style) snow guards.

Clamp mounting to standing seam

This (mechanically attached) method uses a seam-clamping fixity and is a measurably secure option for a SSMR profile, only if evidence of adequate testing is presented to prove it. The clamps attach directly to the roof seam using setscrews that do not penetrate the roof.

Clamp-to-seam attachments can easily be mounted after the roof has been installed and will not fatigue due to thermal heating or cooling of the roof (Figure 7). If the correct quality checks are followed in product selection, they will prevent potentially voiding the warranties of a long-life, premium roof. Both styles (continuous and discontinuous) are available in the marketplace.

What to expect with clamp-mounted attachments

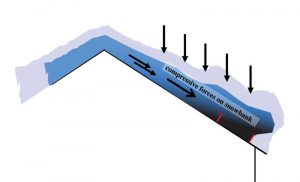

The sliding force of the snow is transferred to the clamp and then into the roof panels, specifically the seams. The holding strength of such a system should be quantified through rigorous testing and proven to resist the service loads on any given job. Test results vary widely on different SSMR profiles and materials. Therefore, test results should be specific to the brand of roof manufacture, profile, material, and gauge thickness used on the project. It is recommended to consult the vendor’s website for test results and lab reports.

Attaching to the building structure

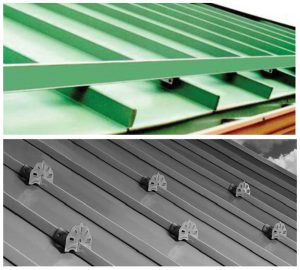

The second method for mounting snow retention is a system that attaches snow guards through the roof and into the building structure (also a mechanical attachment). Attaching to the building structure provides a secure and reliable method if properly tested, designed, installed, and waterproofed (Figure 8). It is only suitable for a roof that is attached the same way (i.e. with screws penetrating the roof’s surface). It should not be used on a SSMR, as it violates the latter’s design intent.

What to expect with structure attachments

Snow guards that attach directly to the structure require penetration for anchorage of snow guard brackets, hence weatherproofing for the long-term service life of the roof is of paramount importance—including sealant protection from ultraviolet (UV) exposure and over-compression of the seal. Such waterproofing requires a high degree of expertise in design, sealant chemistry, selection/sourcing, etc. If sealants/gaskets are not factory applied by the vendor, it falls in the hands of the contractor to select and apply appropriate waterproofing.

The strength of the structural attachment mounting method should be proven and matched to the in-service loads to which the snow guard will be exposed. Again, testing should be specific to the deck and/or structural substrate being actually used on the project. These proven holding strengths then determine snow guard population to the specifics of the project scientifically, not by guesswork.

Using an adhered guard

The third type of snow retention is a stick-on part (chemical attachment). Some variations employ a factory-applied adhesive while others use a field-applied one. Adhered products are available in both plastic and metallic alternatives, but in discontinuous styles only. At first glance, stick-on snow guard systems appear to be very convenient and a lower cost option, but that is not the case when labor and material quantities are taken into account. Further, the replacement costs over the life of the roof can be extensive.