Specifying wall cladding fasteners

The basic information needed to analyze the anchorage includes the following elements.

Material properties

This includes properties of the frame profiles, parts, and anchors and specifications for the surrounding wall conditions at the product perimeter. For metals, the thickness, alloy, temper, and strength are needed. Equivalent information for concrete and masonry substrates must be provided.

Project-specific design pressure

The proposed anchorage system must provide a load resistance equal to or greater than the project-specific design pressure. Of primary concern are the dynamic, or ‘live,’ that cause building movement, such as those imposed by wind, thermal expansion, and (in appropriate location-dependent cases) seismic activity, impact of hurricane wind-borne debris, or potential for blast waves. Wind loading is determined based on the expected maximum wind velocity that is likely to be experienced at the building location, as typically derived from the current, or code-cited, American Society of Civil Engineers/Structural Engineering Institute (ASCE/SEI) 7, Minimum Design Loads for Buildings and Other Structures.

A contributing factor will be the weight of the glass of the type and thickness required to resist the wind loading, as determined by ASTM E1300, Standard Practice for Determining Load Resistance of Glass in Buildings. A rule of thumb is to use a glass type and thickness that just exceeds the required strength of the glazing.

Design load-bearing capacities

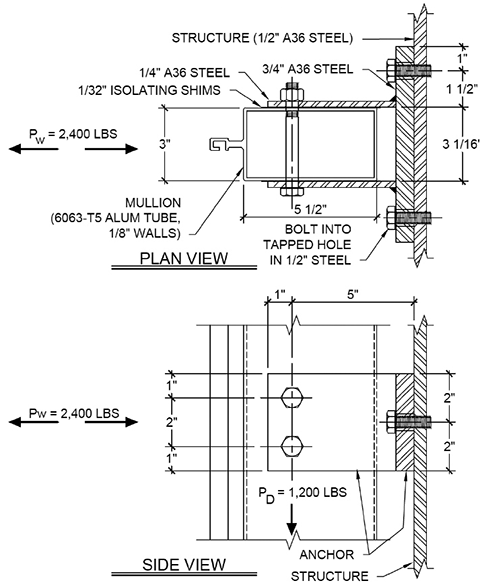

Design load-bearing capacity of fasteners for the surrounding wall substrate material should be considered. With respect to loads, a fastener system is primarily exposed to either tension, shear, or a combination of the two, depending on the configuration.

Load-bearing analysis equations presented in TIR-A9 are the basis for determination of the values used in the document’s load tables, which provide allowable tension, shear, and bearing loads for a range of different fastener sizes, carbon steel, and stainless steel alloys. A total of 21 fastener sizes are covered, ranging from #6-32 through 1-8.

The tensile strength or pull value of a connection is the amount of force required to pull a fastener apart by securing one end and pulling up on the other end. The shear strength of a connection is the force required to pull the base material in one direction and the top material in the other direction (a shearing motion) until failure.

AAMA TIR-A9 walks through the derivation of equations used to calculate these and other parameters when different substrate material and thickness and various fastener types and sizes are used, as well as different hole thread configurations (e.g. UNC and SAE spaced threads).

Since a fastener’s load capacity depends on its size and the material of which it is made, the easiest way to evaluate the loaded performance of various size fasteners and fastener metals is from a load table, such as those published in this revised TIR. Additionally, many manufacturers publish load tables specific to their own fasteners.

TIR-A9 also provides:

- expanded information in the allowable bearing at bolt holes section, which includes screws and screw tilting in various thicknesses and substrates;

- updated information in the pull-out strength section to include equations for thick, thin, and transition regions and include thread stripping of internal and external threads;

- tables showing hole and drill size for spaced threads tapping screws for Type A, C, AB, B, BF, BP, BT, D, F, and T steel in various substrates; and

- minimum spacing and edge distance guidelines for bolts and screws, with separate information noted for those that are intended for use with aluminum substrates.