by Michael L. Rupert

The past few years have seen several highly publicized incidents involving window and balcony glass breaking spontaneously and falling from high-rise buildings in Toronto, Chicago, Las Vegas, and Austin, Texas. While such episodes are rare, the danger they pose has forced building code writers, architects, government officials, and related industry professionals to reconsider which types of glass should be specified for glass applications where strength and protection of passers-by are paramount.

For architects and specifiers, it is important to have an overview on the potential causes of spontaneous glass breakage, including some common misconceptions about its actual spontaneity. The term ‘safety glazing’ generally refers to any type of glass engineered to reduce the potential for serious injury when it comes into human contact. In addition to balcony glass, safety glazings are commonly required for:

- sliding glass doors;

- shower doors;

- patio furniture;

- skylights;

- oven glass; and

- automobile windshields.

Tempered, laminated, and heat-strengthened glass

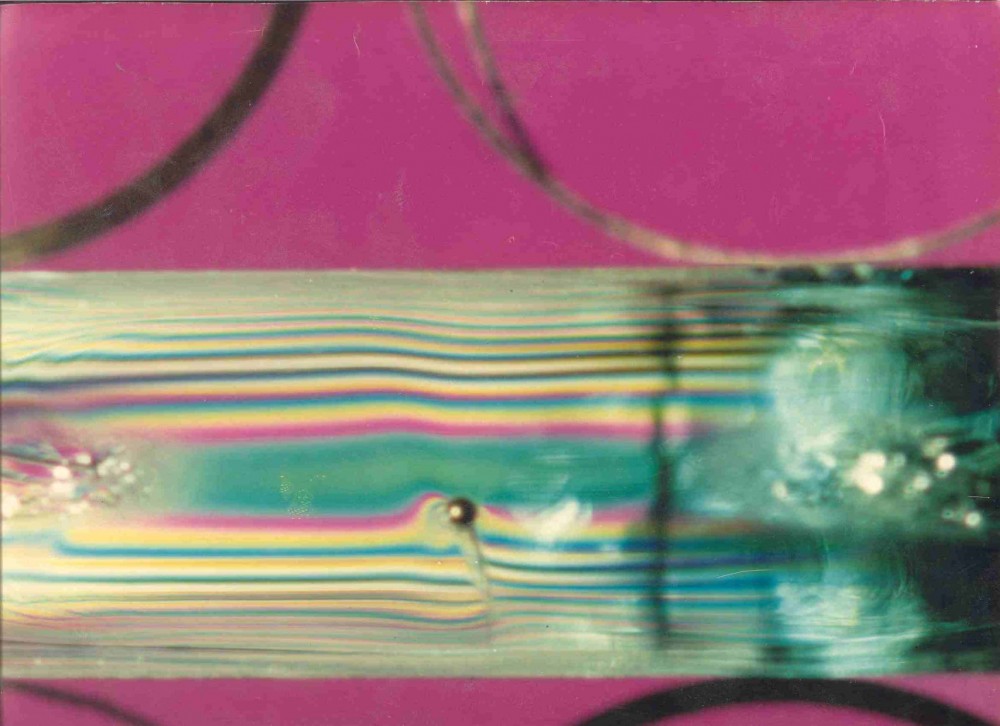

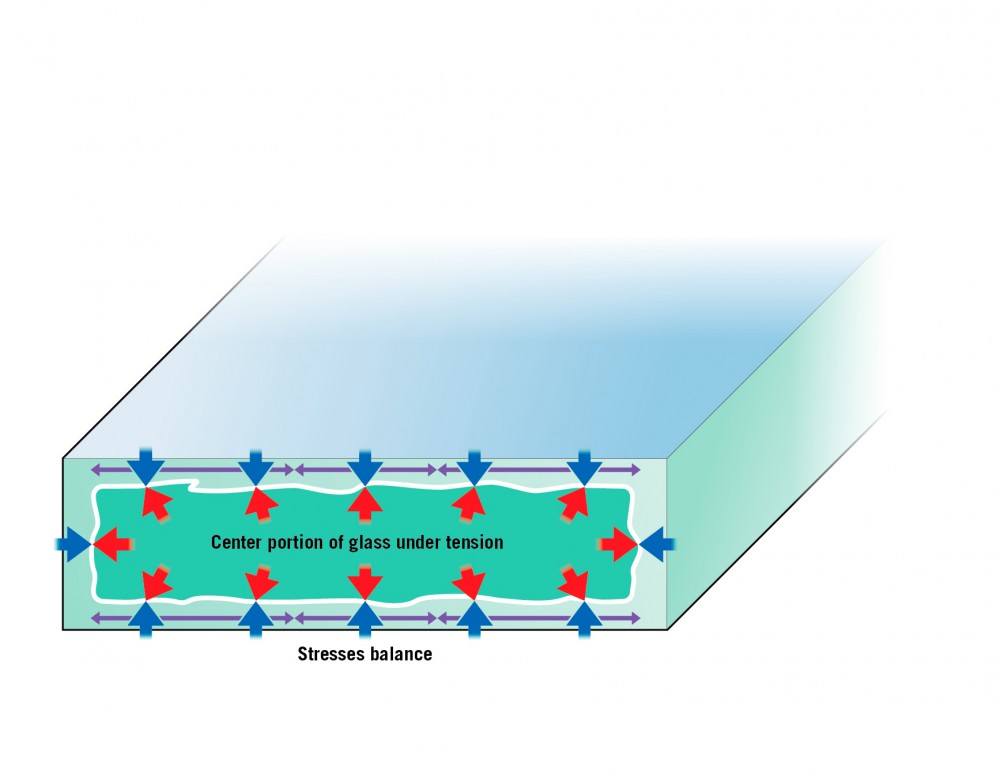

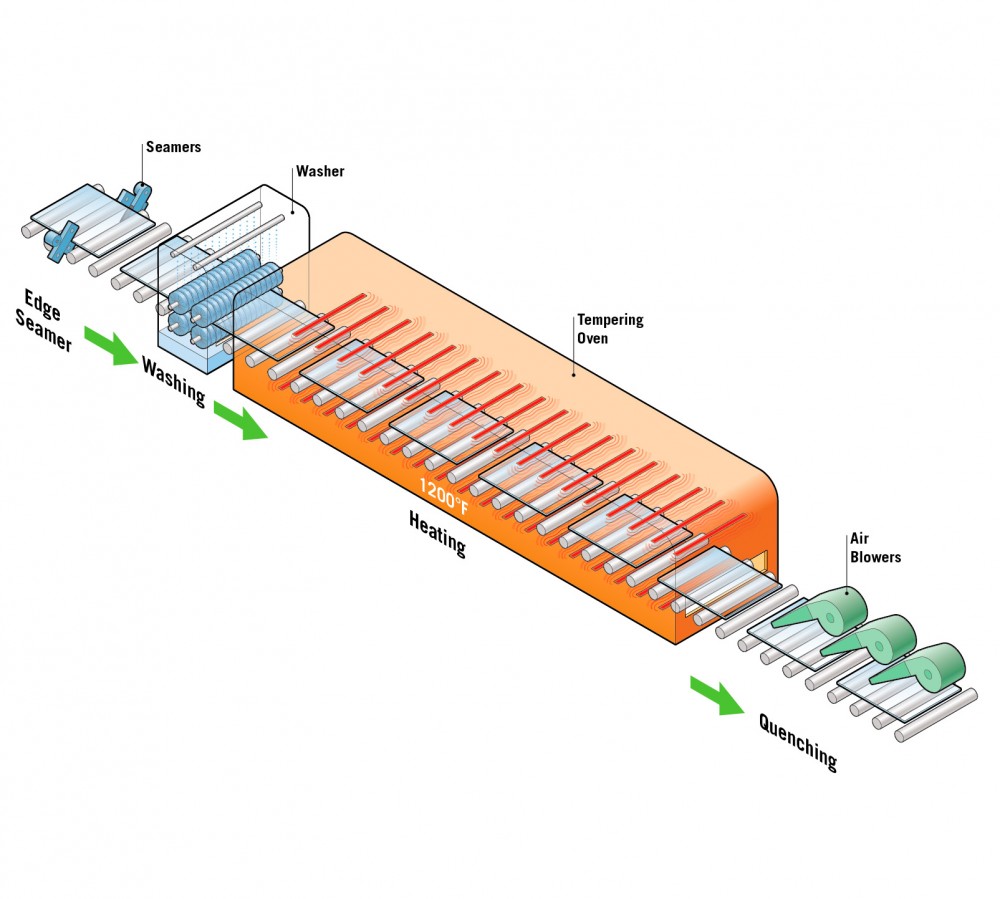

The most common type of safety glass is tempered glass, which is made by heating pre-cut panels of glass to about 650 C (1200 F), then cooling them rapidly through a process called ‘quenching.’ By cooling the outer surfaces of the panel more quickly than the center, quenching puts the surfaces and edges of the glass in compression and the center of the glass in tension.

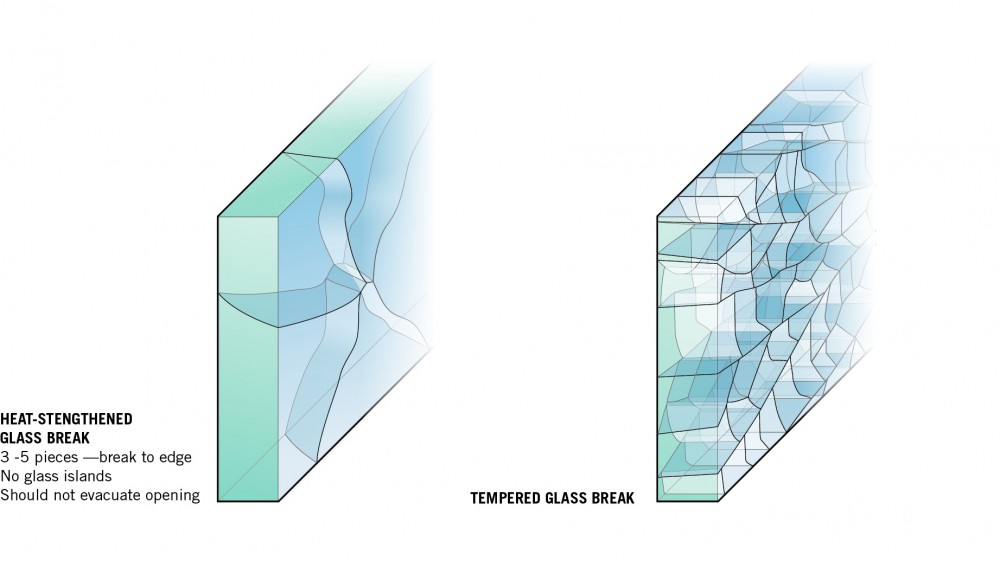

In addition to making tempered glass four to five times stronger than conventional annealed glass, re-heating and rapid quenching dramatically changes the break characteristics of the glass. Consequently, when tempered glass is broken, it shatters into thousands of tiny pebbles—this practically eliminates the danger of human injury caused by sharp edges and flying shards.

Another type of safety glazing, laminated glass, is made by sandwiching an interlayer of vinyl (typically polyvinyl butyral [PVB]) between two layers of glass to hold the panel together if it is broken. Although laminated glass is most commonly associated with windshield glass for automobiles, it is increasingly being specified for storefronts, curtain walls, and windows to meet codes for hurricane-resistant glass.

A third option, heat-strengthened glass, is not technically a safety glazing. This is because when it breaks, it may form larger sharp shards that can cause serious injury. However, heat-strengthened glass still meets Consumer Product Safety Commission (CPSC) 16 Code of Federal Regulations (CFR) Part 1201 and Class A of American National Standards Institute (ANSI) Z97.1, Safety Glazing Materials Used in Buildings?Safety Performance Specifications and Methods of Test, for many safety glass applications when it is combined with a laminated interlayer that holds the glass together if it breaks.

As with tempering, heat-strengthening involves exposing pre-cut glass panels to temperatures of up to 650 C, but with a slower cooling process. Heat-strengthened glass is not as strong as tempered glass because the compression strength is lower—about 24,130 to 51,710 kPa (3500 to 7500 psi) compared to 68,950 kPa (10,000 psi) or greater. However, it is about twice as strong as annealed glass. For this reason, heat-strengthened glass is often specified for applications demanding resistance to thermal stress and snow- and wind-loads.

Causes of glass breakage

The incidents of spontaneous glass breakage in Chicago, Las Vegas, Austin, Texas, and Toronto occurred exclusively with tempered glass. Despite that material’s high levels of strength and capacity to meet safety glazing requirements, it is uniquely vulnerable to these types of failures. Ironically, the center tension zone engineered into tempered glass through the quenching process is also what makes it so vulnerable to catastrophic breakage.

Poor edge quality

There are many potential causes for spontaneous breakage of tempered glass. The most common is damage to the edges of glass as it is being pre-cut into panels, or nicks or chips to the edges that occur when the glass is being packaged, shipped, or installed onsite.

While such damage may not be readily apparent, stress concentrations around these imperfections can occur as the glass expands and contracts in response to in-service temperature changes, wind load, building movement, and other environmental factors. Ultimately, when those stresses cause the glass to break, the action may appear to have been spontaneous when, in fact, the circumstances for failure had been put in place months or even years earlier.

Frame-related breakage

Expansion and contraction of glass framing members may also lead to frame-related breakage—another common form of seemingly spontaneous failure. Such incidents occur when the gaskets, setting blocks, or edge blocks in a metal window or curtain wall frame are missing or do not sufficiently cushion the glass against glass-to-metal contact caused by temperature or wind-related movement. This can cause edge and surface damage to the glass as it comes in contact with the metal frame’s perimeter, producing stresses that eventually lead it to fail for no apparent reason.

Thermal stress

Another potential cause of spontaneous glass breakage is thermal stress. Thermally induced stresses in glass are caused by a positive temperature difference between the center and edge of the glass lite, meaning the former is hotter than the latter. The expansion of the heated glass center results in tensile stress at the edge of the glass. If the thermally induced stress exceeds the edge strength of the glass, breakage occurs.

Accounting for thermal stress is especially critical today, as current design trends and the desire for daylighting are driving the industry toward the specification of larger insulating glass units (IGUs) with high-performance solar control coatings. Large IGUs have inherently greater glass surface and edge areas. When they are combined with coatings designed to manage the sun’s energy, more rigorous thermal stress analyses are required.

Nickel-sulfide inclusions

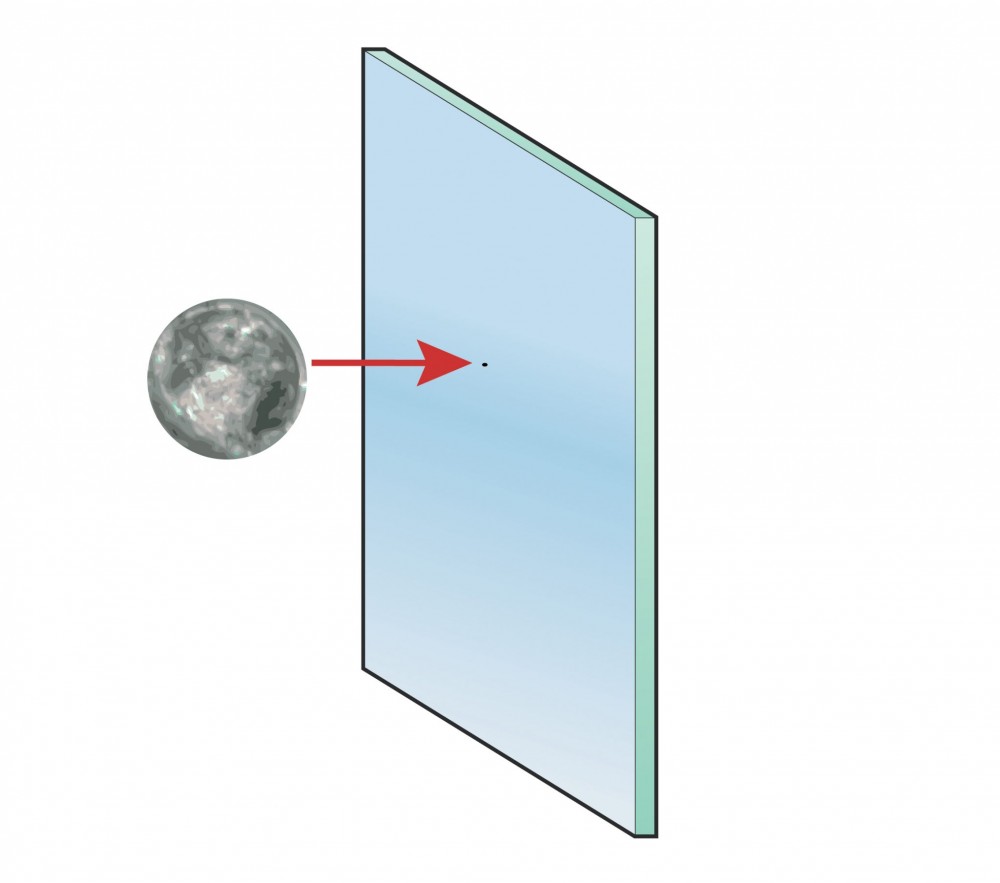

A far less common—but often cited—cause of spontaneous glass breakage is nickel-sulfide (NiS) inclusions in tempered glass. Small nickel-sulfide stones can form randomly in the production of float glass. They are typically benign, even when occurring in tempered glass.

North American glass manufacturers do not use nickel in batch formulations for primary glass and go to great lengths to avoid nickel-bearing components in their glass-melting processes. Despite rigorous quality controls and procedures aimed at reducing the likelihood of nickel-sulfide stones, there is no technology to completely eliminate their formation in today’s float glass.

Nickel-sulfide stones are quite small and their occurrence in the final glass product is covered under ASTM C1036, Standard Specification for Flat Glass, which permits blemishes (including nickel-sulfide particles) of between 0.5 and 2.5 mm (1/50 to 1/10 in.) in float glass, depending on glass size and quality.

While nickel-sulfide inclusions may be present in annealed or heat-strengthened glass, the problems they cause are specific to tempered glass because of the tempering process. Breakage is due to a volumetric growth in the size of the stone. As detailed earlier, during the annealing and heat-strengthening processes, glass is cooled at slower, controlled temperatures that enable nickel-sulfide particles that are present to complete a phase transformation (known as the ? to ? phase change) during which they fully expand to their final size and remain stable thereafter.

In the tempering process, this phase transformation is arrested during rapid quenching, which causes any nickel-sulfide particles present to remain confined to their shrunken, pre-transformation states. Then, when the tempered glass is exposed to higher in-service temperatures caused by solar heat gain or other high-temperature influences, nickel-sulfide particles have the potential to resume their volumetric growth. If the expansion is large enough—and the particle is located in the center tension zone of the tempered glass panel—the resulting stress may be enough to shatter the glass.

Is heat-soaking a solution?

As indicated, nickel-sulfide particles are tiny, extremely rare, and only found randomly in float glass. This combination makes visual inspection for such inclusions highly impractical, if not impossible. For that reason, some glass fabricators and glazing contractors offer heat-soaking of tempered glass as a potential solution for minimizing the risk of spontaneous glass breakage.

In this procedure, the glass supplier exposes an entire lot or statistical sampling of tempered glass panels to temperatures of 288 to 316 C (550 to 600 F) for two to four hours. The goal is to initiate or accelerate the phase change of any nickel-sulfide inclusions that may be present and to cause the glass to break before it is shipped to the end customer.

While this ‘break-now-instead-of-later’ procedure may eliminate defective tempered glass panels by destroying them before they are shipped, it cannot provide a 100 percent guarantee against spontaneous breakage. Even advocates of heat-soaking are careful to state the procedure can only reduce or minimize the risk for spontaneous breakage of tempered glass. They will not use words such as ‘prevent’ or ‘guarantee.’

Risks of heat-soaking

There are risks associated with the heat-soak procedure that may outweigh any perceived benefits. For instance, small, stable inclusions could undergo the beginning of a phase change during the heat-soak. While the phase change may not be sufficient to cause breakage during the procedure, the transformation could potentially continue after the glass is installed, causing it to break in-service.

Re-exposing tempered glass to the increased temperatures of heat-soaking also has the potential to reduce its surface compression, which is the source of its strength. Ultimately, this may undermine the glass’s ability to fulfill the safety or strength requirements for which it was intended.

Further, heat-soaking adds another layer of handling to the manufacturing process, which creates more opportunities for edge damage, scratches or color changes to the low-e coating, and other imperfections that could have an impact on the tempered glass unit’s long-term durability and performance.

Solutions for safety

In recent months, two organizations made major announcements prompted largely in response to the incidents of falling glass in Toronto, Chicago, Las Vegas, and elsewhere. Both shared a common assessment—namely, that using laminated tempered glass or heat-strengthened glass is the most viable solution to making balcony and other types of overhead glass safer.

In Canada, an Expert Panel on Glass Panels in Balcony Guards established by the Ontario Ministry of Municipal Affairs and Housing (MAH) recommended local building codes be amended to mandate the use of heat-strengthened laminated glass for any outboard guard or glazing located beyond the edge of a floor, or within 50 mm (2 in.) of the edge of a floor. For outboard glazings located more than 50 mm inward from the edge, the panel recommended heat-soaked tempered glass or heat-strengthened laminated glass.

Similarly, in December 2012, the International Code Council (ICC) passed a code change proposed by the Glazing Industry Code Committee (GICC), mandating use of laminated glass in handrail assemblies, guardrails, or guard sections. The newly approved code states laminated glass must be constructed of either single fully tempered glass, laminated fully tempered glass, or laminated heat-strengthened glass, and comply with CPSC 16 CFR Part 1201 or Class A of ANSI Z97.1.

Conclusion

Given the developments and recommendations outlined in this article, it is clear a laminated glass interlayer in combination with tempered or heat-strengthened glass may offer the optimal blend of characteristics for applications where the risk of injury from glass fallout is a primary concern. For non-safety glass applications, where strength and resistance to spontaneous breakage is desired, non-laminated heat-strengthened glass should be considered due to its lower costs.

Michael L. Rupert is PPG Industries’ director of technical services and product development for flat glass. A 39-year company veteran, he is a board member for the Glass Association of North America (GANA) and chairs the Flat Glass Manufacturing Division. Rupert holds a bachelor’s degree in civil engineering and an MBA from the University of Pittsburgh. He can be reached at mrupert@ppg.com.

Glass breakage especially on high rise buildings can frequently be caused by bird impacts. Not necessarily by defects or inclusions in the glass. We have several possible solutions to reducing or eliminating bird impacts using digitally printed ceramic ink/frit baked-onto glass.

We also have self-adhesive films that can be applied to existing glass. These films can be set up to automatically become opaque when sunlight heats the glass/glazing. In addition, images can be projected onto the films during the dark periods that typically will alert birds to the glass/glazing and avoid impacts. We offer Technical Service and Support.

We have another sort of problem with glass breakage. Our overhead canopy has large glass panels approximately 6′ x 10′. We believe birds drop rocks from our rooftop on the 8th floor, thereby shattering the panels. These cost us approximately $2000 each panel. We’re looking for something to put on the glass to maintain the esthetic appeal but protect the glass. Any ideas?

Either replace the glass with polycarbonate sheet or cover the glass somehow with it.

This glass can be made safe with the application of clear safety film applied to the glass and then anchored to the frame with a structural silicone

Install sheer net above

How to avoid spontaneously “BLAST” of glass (of about 7mm thickness) which is properly tightened to steel frame, How to verify others mounted glass to avoid this??

Kumar

is this blast in Saudi Arabia ?

Hi there

Why did you choice Saudi Arabia. Is it common there.

Mr.Kumar

Where is the location of this blast? How did you measure this 7mm? How far it is from edges? Send me a picture. Give complete details in order to advise

Send me a picture- a detailed picture to support you. my email id : vgssreddy@gmail.com

Suddenly a full glass has broke ….the glass is from celling to floor ……there was no external force on it …… The glass is full shatter but didn’t fall down

I have an issue for hotel shower wall glass, it suddenly shatter at early morning when guest inside the room sleeping luckily it not drop to the bed room as it so near with it & it been laminated/film sticker. He only have minor injured as he touch the shatter surface when he trying to check what is happening. Can you advice what is this cause?

Can one tell by the breakage or radiation pattern – the most likely cause of the damage?

Ihave a cupboard door which spontaneously shattered after 4years.All the screws were protected by mushroom shaped plastic covering apart from the one in line with the centre of the radial cracks.Could this be the reason after 4 yrs.It does not stand in direct sunlight and room temperature constant.

how can we determine the point of entry of holed damage on a 1inch thick tempered glass?

I had a double pane window crack on the inside only, however, it looked like it was from the impact of something that would have had to have been from the outside. Is this possible?

We ordered triple glass unit with heat strengthened inner lite instead of tempered.

Is there any solution for this?

Thanks for providing this information.

I have a 2mm chip in the inside of my hurricane impact door. You cannot feel it from the inside or the outside as it is in between the glass. The vender says it is too small to worry about. I feel as if it is compromising the integrity of the door and is still under warranty and should be replaced. Thoughts?

Hi Kristin,

If the glass in question is tempered glass, then the chip was in the glass before it was tempered. This is because you can’t chip tempered glass, it always shatters. In which case your supplier is correct in his assessment.

If howvere, the glass is plain float laminated and is chipped, then there is a slight inherent weakness at the point of the chip, which could lead to cracking in the future if the glass is stressed.

Ourshower door exploded at about 1:30 am this morning. We were sound asleep and no one wad in the bathroom,thank goodbess.

Excellent article ; Very informative, concise and to the point.

Bernard Heeney, Jones Engineering group, Ireland

We have a terrace aluminium sliding door. We rested carton to eliminate the sun’s rays from entering. We went back to our apt. and found the glass was broken. We have a good idea as to how glass was broken, but we have been told that by resting carton on glass, this causes thermal breakages. Is this possible? If we had to do curtains or blinds, wouldn’t these have the same effect? Please help. I also have photos of breakage in case anyone wants to see.

Hi, Yes this is possible. The thermal breakage risk is higher, when the glass is partially covered/shaded.Because it causes glass to heat and cool at different areas, leads to occur thermal stresses. And for curtains, it will be the same results, unless you keep a sufficient distance/gap ( more than 150mm) between the glass and the curtain for proper ventilation, then it will reduce the risk of heating the glass due to solar reflection caused by the curtain.

In solar module manufacturing, sudden breakage of glass inside laminator which point of propagation is at edge could it be because of inclusion or stone?

Having a high quality tempered glass is very important,I don’t know how to select the best tempered glass. Pls give me some suggestions.

My window has spontaneously shattered on a hot night. Should the manufacturer pay? They say No As it is over 3 years warranty.

Hi

I have one incident on my handed over project. Laminated balustrade slope glass has broken and hanged outside. There was no impact mark on glass. no pattern for spontaneous breakage. Even how come both internal glass has broken.

Any faced similar situation and can guide.

Ramesh

Good day Michael L. Rupert! I am impressed by reading your article, I found it a very informative post about Spontaneous Glass Breakage: Why it happens and what to do about it. This post is very useful for everyone. Your article is great I loved it and i will love to read more from you, dear.

Is there any damage possibility if cutting on window frame wood no closer than 3/4″ from the bottom edge of a 1/2″ thick 6′ x 6′ tempered glass window? I need to remove some damaged wood for replacement. Will cut using a small circular saw and an oscillating saw.

It’s a nice article to come across as glass breakage is a real thing to deal with if you have installed anything like glass doors, windows, shower doors or something. I like how you have explained the problem and the solution too. I have seen similar information at one place, you can also see on Grandglass.co.nz.

Spontaneous shattering of INTERIOR only of double paned 5’x 7’ fixed panel. Manufacturer insists impact & won’t cover cost. Advice.

mostly damage or brokage are from the edge of the glass- get these edges well protected then it s safe

Does toughened glass explode spontaneous causing glass pebbles to be thrown all over

yes it happened in my house on 24july morning 2023.

with a very high thud noise.

reasons unknown

You would get to know about the spontaneous glass breakage and why it happens and what to do about it. I enjoyed reading this article. It makes the work straight and easy for us. I like the way they have researched and presented it in front of us.

We have experienced similar issue and seek an international consultancy firm to get engaged for a project in the Middle East

Please let us know if anyone interested and have the capacity.

Good morning, I have this problem this morning I just the sound only to wake up and find my glass table all shuttled into small pieces, without any crack or anybody to temper with it, what could cause this, am really shocked and afraid.

I had a horroble incident happened with 12mm stardard glass full size placed on my garrage roof suddenly get broken 2 days after i put a PARANET directly on top of it.

I have a picture window toughened double glaze. One night last week I went to draw the bedroom curtains and the whole of the inside panel of glass had shattered but not fallen . It seems to radiate from the top of the panel , right. hand side .

The company hasn’t seen it yet , but are telling me it must have been hit

I am seventy plus years old , not in the habit of throwing things against a window and nobody has been in my house ,family wise , or workman since last March ( covid ) !!

How do I approach this ? from the UK

Exactly. Same thing happened to our patio door two weeks ago. Sent pictures to the manufacturer and they said it was caused by “impact”. Won’t warranty it. We’re 70 years old also. No grandkids. So how does a layperson argue the case?

I had a Pyrex baking dish explode. It was room temperature, sitting on the kitchen counter. No heat, no cold, it just blew up. I was a science teacher, endured my share of Physics, and I’m flabbergasted. A buddy mentioned, “Rupert’s Glass Drop”, which is interesting as heck. I guess it was due to stress over time, kinda like when people blow up. Still a most curious phenomenon…any insight out there?

I have 2 layer of tempered glass using as mould bulk polymerization of pmma, but how can little stratch appear and make surface of tempered glass not smooth

what is the percentage of tempered glass Spontaneous breakage ?

Is there is any standard .. please advise

My driver rear side door window shattered On my brand new 2021 Ford F2 50 has anyone ever heard of this happening?

Octogenarian couple second owners of 1 1/2 year old home had spontaneous collapse of one of 3/8″ glass shower enclosure panels, a right angle notched 80″ x 42″ panel. Could nightly change in set thermostat temperature of only 4 degrees, 74F to 70F degrees have a part to play in this unexplainable occurrence? June 19, 2021, 9:30 pm.

This is fascinating information! Is there an explanation for why one of two halogen bulb lenses in a porch fixture would break at night? This pair of lights has been used extremely infrequently. Temperatures are moderate in daytime and drop above freezing at night this October on the outer banks in NC. Unless I have an unknown enemy who shot it, I can’t think of a reason why broken glass would have appeared on my doorstep from the old Phillips 90W bulb. I replaced both bulbs and the fixture is working fine now. Thanks for reading and for any information you might have!

my washroom’s toughened glass spontaneously got broken with a very high thud noise.

the reason are unknown. Thoush it was laminated from outside.

the room temperature was around 30 degree Celsius.

there was no person in the washroom or nearby.

the weather was totally clear.

no speedy winds or cloud.

may I know how safe these classes are?

what is the alternate of these glasses?

Hi, The part glass wall in our hall shattered into tiny bits at 01:30 the other morning. It was not not or cold, does not get sunlight on it and we were in bed! It took a while to crack all the way. It’s still in place but each time I passing there are you shares of glass on the floor. We haven’t touched it. Is there a stick on covering we can put on it, to stop it falling out? (Until the joiner can book is in? We are in Scotland, UK. Thank you :-)

What is the term used for the squares of broken safety glass?

i searched this topic because recently, our glass mug on the dish draining tray, just broke by itself into pieces which even surprised me. Glass mug is by a know brand (specializing in microwavable dishes, glassware, etc). it is not like glass shattering on cement, but like exploding into small almost same size bits. wierd actually.