Stopping sound: The advantages of highway precast wall barriers

by Catherine Howlett | January 5, 2013 12:05 pm

[1]

[1]by Tom Kuckhahn, PE

Federal, state, and local specifiers continually seek affordable, durable, and aesthetically pleasing wall solutions to border bustling highways and adjacent neighborhoods. The principal purpose of these is typically to provide citizens with a visual barrier to the highway and sometimes to mitigate traffic noise.

Today, highway barriers cover thousands of miles of federal roadways. When the walls first began to appear in the 1960s, they were modeled after wooden fences. Now, things have changed––according to the Federal Highway Administration (FHWA), almost half of the highway walls constructed in North America to date are made of concrete. (See Section 5, “Noise Barrier Materials and Surface Treatments[2],” in the U.S. Department of Transportation (DOT) Federal Highway Administration’s (FHWA’s) Noise Barrier Design Handbook.) While wood, metal, brick, and masonry block also comprise some of the roadway walls sprawling the country, concrete panels have emerged as a preferred solution that meets many affordability, durability, and aesthetic specifications and preferences.

Limiting the noise

In addition to functioning as a visual shield, highway walls serve as barriers to help break the path of sound traveling from freeways to neighboring homes and buildings. Most highway noise barriers force sound to travel a longer path over and around the barrier. Effective highway walls typically reduce sound levels by five to 10 dB. Since sound levels are measured using a logarithmic scale, a reduction of nine decibels is equivalent to elimination of more than 50 percent of the unwanted sound. (See “Highway Traffic Noise Barriers at a Glance” from Keeping the Noise Down: Highway Traffic Noise Barriers [3]by the U.S. DOT’s FHWA.)

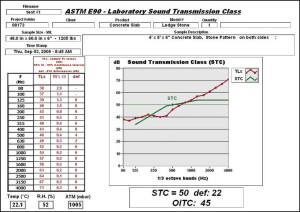

Sound transmission class (STC) is a single number rating of a material’s ability to resist airborne sound transfer at frequencies of 125 to 4000 Hz. In general, a higher STC rating blocks more noise from transmitting. According to the results of a sound transmission test conducted by Element Materials Technology in Saint Paul, Minnesota, a 152-mm (6-in.) thick concrete panel weighing 547 kg (1205 lb) has an STC rating of 50, an outdoor-indoor transmission class (OITC) rating of 45, and a deficiencies rating of 22. (Element Materials Technology [formerly Stork Twin City Testing Corp.] presented “Sound Transmission Class Testing Ledge Stone Panel,” to a manufacturer on Sept. 4, 2009.)

These ratings meet the sound-limiting specifications for highway wall barriers. The STC value was obtained by applying the transmission loss (TL) values to the reference contour of ASTM E413-04, Determination of Sound Transmission Class.

[4]

[4]The actual transmission loss at each frequency was calculated by the following equation:

TL = NR + 10logS – 10logA2

TL = transmission loss (dB)

NR = noise reduction (dB)

S = surface area common to both sides (sf)

A2 = sound absorption of the receiving room with the sample in place (sabins)

OITC procedure ASTM E1332-03, Determination of Outdoor-Indoor Transmission Class, was followed in every respect. Basically, OITC was calculated by using the sound transmission loss values in the 80 to 4000 Hz range as measured in accordance with ASTM E90-04, Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements. These transmission loss data are then used to determine the A-weighted sound level reduction of the specimen for the reference source spectrum specified in ASTM E1332, Table 1. The appropriate calculations were made to determine the OITC value.

Standing its ground

Durability is a critical factor specifiers must evaluate to determine what kind of material should be used for a municipality’s highway walls. Durability depends on a structure’s ability to withstand extreme loads, and is often reflected by the ability to resist bending. Measured by loading un-reinforced panels, flexular strength is expressed as the modulus of rupture (MR) in pounds per square inch (psi). The results of such tests enable designers and constructors to assess the resistance of highway walls to wind and seismic loads.

Concrete construction is, in general, exceptionally strong. It gains most of its strength in the first 28 days, but it continues to gain strength over its life. Hydration causes the compounds in cement to elongate. As the compounds lengthen, they intertwine and create an impermeable surface. According to Precast/Prestressed Concrete Institute (PCI), precast easily achieves a strength of 34,474 to 48,263 kPa (5000 to 7000 psi) or more (See “Sustainability FAQ[5]” by the Precast/Prestressed Concrete Institute (PCI).)

Not your fair-weathered wall

Due to their durability, precast highway walls are able to withstand varying weather conditions better than their wooden counterparts. Wood is porous and, as a result, tends to absorb moisture, which causes expansion. The wood contracts as it dries out. Frequent expansion and contraction eventually contributes to gaps between planks for mildew to grow.

Wooden sound walls typically require significant maintenance after five or 10 years because of weather degradation from sun, water, and salt. Sun bleaches paint and stains, quickly eliminating the protective wall coatings. Once the stains are gone, water easily seeps into the wood panels. Over time, this results in significant structural degradation. In snowy climates, the salt wash that results from snow plows introduces chloride to the wood, which further degrades the panels. Cold climate regions face the threat of additional wear and tear on their walls as a result of moisture freezing and thawing.

[6]

[6]Data courtesy Element Materials Technology

Precast walls are built to withstand an assortment of weather conditions. Sun does not degrade them to the extent it does wood walls. Since hydration actually helps build concrete’s strength, water does not damage precast walls. Concrete’s inherently impermeable surface prevents chloride from road salt from migrating into the concrete. Properly air-entrained concrete is designed to withstand the freeze-thaw process and can last for decades without degrading. The air structure within concrete provides a place for frozen water to expand, preventing the confinement required to push apart and degrade concrete in the first place.

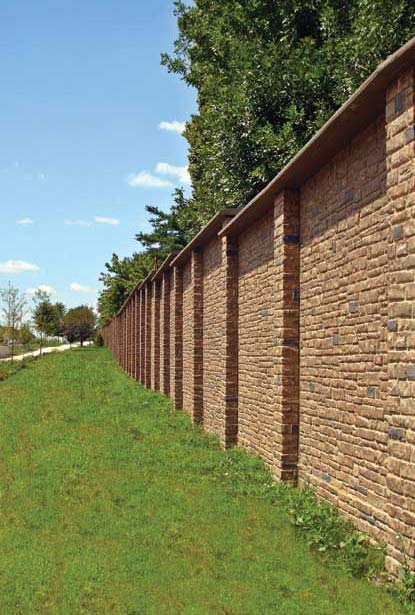

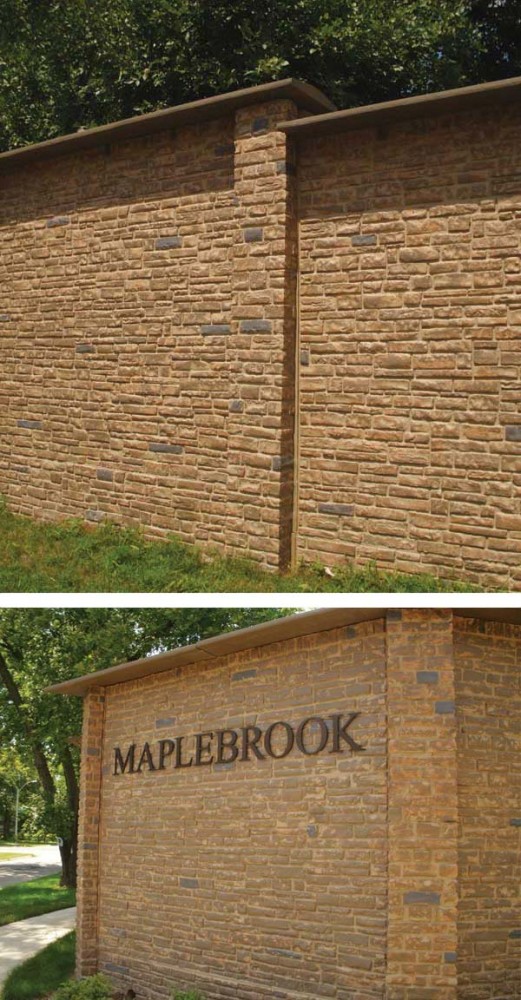

Low-maintenance aesthetics

Aesthetic value is another appealing aspect of precast sound walls. Concrete walls require minimal maintenance to preserve their ‘posture.’ While sun fades the stains and paint of wooden walls, there is no need to add a layer of paint or stain to most precast walls. Instead, concrete can be tinted with a permanent hue that does not wash away or fade as highway walls bake in the sun. Many U.S. Departments of Transportation (DOTs) are selecting buff-colored tints that resemble indigenous rock, limestone, or other surroundings. When entire highway walls are stained with earth-toned shades, they easily camouflage into their natural environment.

Neighboring communities also often appreciate the aesthetic value offered by precast sound walls. Historically, the walls were only finished on one side, so either highway passengers had to view the less attractive side, or else the neighbors had to. Now, finishes can be applied to both sides of the highway walls.

Maintenance for precast walls is simple. As concrete walls get coated in dust, dirt, and other elements, a sporadic high-pressure wash-down is all that is necessary to make the wall look as good as new. Re-caulking once every 15 years eliminates fissions that can develop over time. Conversely, other building materials require much higher maintenance. With precast concrete, less than one percent of its surface area is caulked, compared to 20 to 30 percent of brick surface area that is mortar.

Masonry is also susceptible to cracking because of the sheer number of components bound by mortar. When cracks appear, tuck-pointing is necessary. This involves reapplying mortar to all of the joints and is expensive because it takes time to remove old, failed mortar. Since masonry is porous, it requires a sealer (e.g. paint) applied at installation and at regular intervals to control moisture migration from the outside atmosphere.

Rapid construction

Another benefit precast sound walls bring to citizens and specifiers alike is their ability to be expeditiously erected, compared to the installation method of their wooden counterparts. When building wooden sound walls, the construction crew must first plant a long row of columns, and then retrace their footsteps to begin bolting on wood piece by piece. With precast, builders can erect the concrete slabs sequentially, eliminating inefficiencies and expediting the process. Concrete columns are set with a light crane or a rough terrain forklift, and then are grouted in place. Once two columns are set, the walls are slipped into the columns’ slots without requiring any additional connection work. This provides the potential to reduce 15 to 20 percent in a typical sound barrier construction schedule.

The shortened installation time is appealing for construction teams in climates subject to ground-freezing temperatures. For crews that can only install walls nine months of the year while the ground is thawed, rapid installation is a significant benefit. Minimizing road construction time is also important for traffic circulation.

[7]

[7]Photos © Alan Krane. Photos courtesy Fabcon

The bottom line

The durability and weather-resistant nature of precast walls can create an affordable long-term solution for many city and state specifiers. Traditionally, wood has been considered the most cost-efficient option for highway walls. As the price of concrete and precast sound walls has lowered, and lifecycles have been evaluated, it has become clear precast highway walls are nearly equitable to wooden walls in short-term costs. Moreover, precast walls offer significant savings in the long term.

State DOTs paid an average of $172/m2 ($16/sf) for wooden highway walls in 2010. Precast highway walls cost between $172 and $175/m2 ($16 and $16.25/sf), and have a significantly longer lifecycle. Considering that wood panels last an average of a decade and precast panels typically last between 20 and 40 years, one can calculate a minimum savings of $169.50/m2 ($15.75/sf) after 10 years with precast walls.

In addition to their long lifecycle value, precast highway walls have a sustainable component that appeals to forward-thinking communities and specifiers as well––they can be disassembled and re-constructed, since the panels themselves are not connected to columns. Instead, they are attached to columns through a tongue-in-groove system. When a major road project is underway and crews need to take down the sound walls, all they must do is slide the panels out of the columns. Rather than discard the panels, they can reassemble them to construct another highway wall, saving time and money without sacrificing the durability or aesthetic nature that characterizes precast highway walls.

Tom Kuckhahn, PE, is the vice president of manufacturing and engineering for Fabcon. He has been at the company since 1994. Kuckhahn graduated from the University of Minnesota with a bachelor’s degree in civil engineering and has been a professional engineer since 1999. He can be reached via e-mail at tom.kuckhahn@fabcon-usa.com[8].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/9327-Maplebrook-Verti-Crete-17.jpg

- Noise Barrier Materials and Surface Treatments: http://www.fhwa.dot.gov/environment/noise/noise_barriers/design_construction/design/design05.cfm

- Keeping the Noise Down: Highway Traffic Noise Barriers : http://www.fhwa.dot.gov/environment/noise/noise_barriers/design_construction/keepdown.cfm

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/photo4-5.jpg

- Sustainability FAQ: http://www.dynaspan.com/download/Sustainability_FAQ.pdf?PHPSESSID=c0e215c11dbd8d6eb04d5100dbe6a102

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/test-1-ele-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/01/IMG_1560.jpg

- tom.kuckhahn@fabcon-usa.com: mailto:tom.kuckhahn@fabcon-usa.com

Source URL: https://www.constructionspecifier.com/stopping-sound-the-advantages-of-highway-precast-wall-barriers/