FAILURES

FAILURES

Deborah Slaton, David S. Patterson, AIA, and Jeffrey N. Sutterlin, PE

Widely used in buildings ranging from retail/office complexes to hospitals, storefront and window wall systems are specified for ground-level fenestration and entrances, and for punched and horizontal bands (or ribbons) of windows. Unlike curtain walls, which can span multiple floors, storefronts and window walls are usually limited to spans between floor assemblies.

Storefronts typically have lower performance characteristics than curtain walls. For example, the maximum air infiltration permitted for storefront systems (fixed lights) is 0.3L/s m2 (0.06 cfm/sf) at a 75 Pa (1.57 psf) static pressure differential, as recommended by American Architectural Manufacturers Association (AAMA) SFM-1, Aluminum Store Front and Entrance Manual, compared to 0.3L/s m2 (0.06 cfm/sf) at 300 Pa (6.24 psf) typically specified for curtain walls.

AAMA SFM-1 also recommends a water penetration resistance test pressure of 10 percent of the inward-acting design wind pressure for storefronts, as compared to 20 percent recommended for curtain walls in AAMA MCWM-1, Metal Curtain Wall Manual. Storefronts, window walls, and curtain walls all share a 300-Pa (6.24-psf) minimum test pressure for water penetration. Due to their inherent performance limitations, storefronts are typically restricted to low-rise buildings.

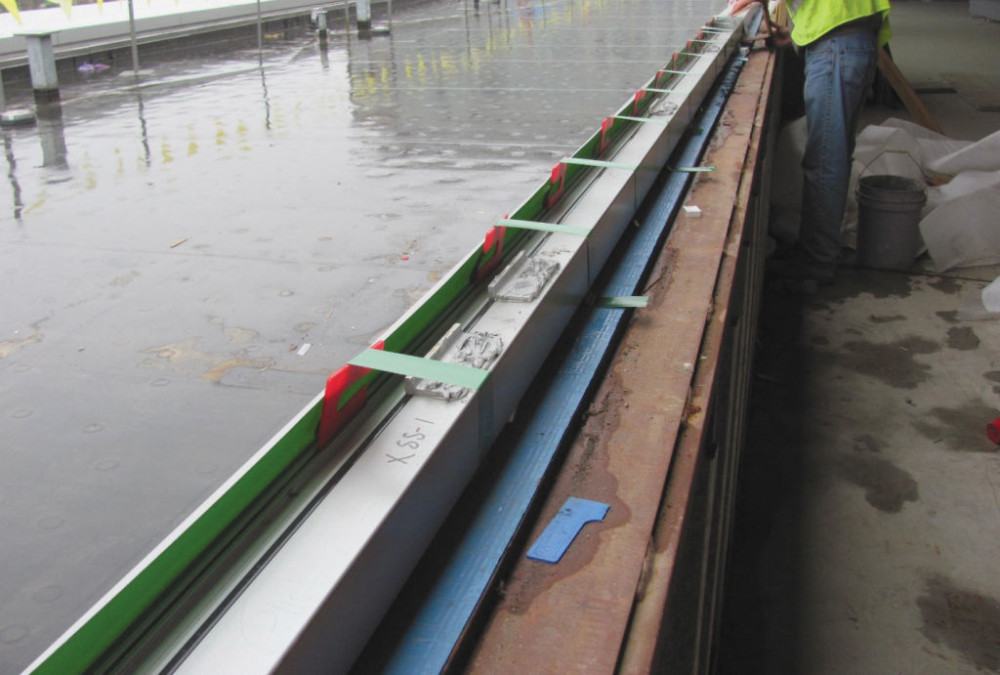

Unlike curtain walls, which manage water through compartmentalization, storefronts and window walls are typically designed to allow water entering the assembly to drain to the bottom of the system, where it is collected by a subsill (or sill flashing) and redirected to the exterior. To prevent water from migrating into the building, the subsill is formed with an integral vertical back leg and fitted with dams at each end to form a gutter.

Although a number of deficiencies can lead to water leakage in storefronts, common problems are often attributed to subsills, which have proven to be vulnerable to water leakage via unsealed fastener penetrations (through the horizontal leg of the subsill) and end dams not sealed watertight or that become dislodged or damaged during window framing installation.

To minimize the potential for water leakage attributed to the subsill, fastener penetrations through the horizontal leg of the subsill should be avoided. Instead, brackets that engage the subsill without penetrating the wet zone should be used. Additionally, to avoid being dislodged during installation, end dams should be mechanically attached to the subsill extrusion and fully sealed to ensure a watertight interface.

An effective field test to confirm the integrity of the subsill installation is a test outlined in AAMA 511, Voluntary Guideline for Forensic Water Penetration Testing of Fenestration Products, for which the drainage mechanisms of the subsill are temporarily sealed (commonly with tape) and water is introduced into the subsill and held for 15 minutes while the interior and underside of the subsill are monitored for leakage. As this is a relatively simple test, and because significant damage can occur from water leakage at the subsill, testing of 100 percent of subsills should be considered during construction where storefronts and window walls are incorporated into the building enclosure.

Deborah Slaton is an architectural conservator and principal with Wiss, Janney, Elstner Associates (WJE) in Northbrook, Illinois, specializing in historic preservation and materials conservation. She can be reached at dslaton@wje.com.

David S. Patterson, AIA, is an architect and senior principal with the Princeton, New Jersey, office of WJE, specializing in investigation and repair of the building envelope. He can be contacted at dpatterson@wje.com.

Jeffrey N. Sutterlin is an architectural engineer and senior associate with the Princeton office of WJE, specializing in investigation and repair of the building envelope. He can be reached at jsutterlin@wje.com.