Images courtesy FGIA

Laboratory testing

A reliable methodology must be employed to obtain uniform and comparable measurements that enable evaluation of different products in a fair and consistent manner. To accomplish this, the Fenestration and Glazing Industry Alliance (FGIA) recently updated its document, American Architectural Manufacturers Association (AAMA) 1801, Voluntary Specification for the Acoustical Rating of Windows, Doors, and Glazed Wall Sections, which describes STL measurement procedures.

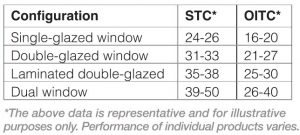

AAMA 1801 prescribes the use of STL test data obtained per ASTM International E1425-14, Standard Practice for Determining the Acoustical Performance of Exterior Windows and Doors. This information is then used to calculate STC and OITC ratings.

Products are evaluated in accordance with a sound spectrum that has been shown to correlate well with the spectra from three typical transportation sources (aircraft, highway traffic, and railroads). This rating system uses OITC classification numbers.

As specified in ASTM E1425, the test specimen is installed into a test opening of a filler wall that has a significantly higher sound transmission loss (at least 10 dB at every test frequency) than the specimen that was being tested.

The gap between the test opening and specimen, which allows for some adjustment if the product is slightly out of square, may not exceed 10 mm (393 mils). However, the perimeter of the test specimen may not be in contact with the test opening. A closed-cell foam isolator pad is placed on the bottom of the test opening to support the test specimen and isolate it from the test opening, and up to a 9.5-mm (3/8-in.) gap is required at the top and sides. The specimen is sealed in place with a dense mastic-type sealant, such as a duct seal compound, at the exterior and interior of the top, bottom, and sides, but not covering more than 6 to 12 mm (1/4 to 1/2 in.) of the test specimen frame so that additional damping is not applied. Weep holes or slots are not covered and a minimal number of shims should be used to adjust the test specimen in the opening.

The average temperature in both rooms of the test area during all acoustical measurements is maintained within the range of 22, ±5 C (71.6, ±9 F). For laminated glass or other temperature-sensitive materials, the average temperature in both rooms and the average surface temperature of the specimen should both be kept within the range of 22, ±2 C (71.6, ±3.6 F). These temperature conditions will minimize thermal effects on the measured STL and ensure better reproducibility among laboratories.

Finally, products are classified and rated based on their acoustical performance in accordance with ASTM E1332 (OITC). Additionally, products are rated based on their acoustical performance in accordance with ASTM E413 (STC).

A guide specification to ensure the appropriate acoustical testing is provided in AAMA Curtain Wall Manual (CWM), an FGIA document:

5.2.3.7 Sound Transmission Perform acoustical tests in accordance with ASTM E90 and ASTM E1425 on the glass type(s) specified in Section 08 80 00 Glazing, rigidly supported in aluminum framing of the same product family. “Glass-only” test results shall not be acceptable.

5.2.3.7.1 Products shall be classified based on their acoustical performance in accordance with ASTM E413 (STC) and ASTM E1332 (OITC). Products shall be rated using OITC classification data.

5.2.3.7.1.1 Outdoor-Indoor Transmission Class (OITC) shall not be less than [25].

Preventing exterior noise from degrading an otherwise quality interior environment requires detailed project specifications, a thorough understanding of the acoustic performance of different combinations of glazing and framing, and reliable test results or certification. Acoustically rated fenestration products are available in many different styles, framing materials, and operating systems, and proper application of AAMA and ASTM standards will help in developing successful design solutions.

Referenced documents including AAMA 1801, AAMA CWM, and AAMA TIR-A1 can be purchased in FGIA’s online store.

Steven Saffell oversees the standards, product certification, and codes and regulatory affairs aspects of the Fenestration and Glazing Industry Alliance (FGIA). His background is a tapestry of architectural firm work, modular design, as well as residential and commercial fenestration experience. He also spent three years teaching as an adjunct professor. He is experienced in managing technical teams, including employee development, operational strategy, and financial management. He can be reached at ssaffell@FGIAonline.org.

Steven Saffell oversees the standards, product certification, and codes and regulatory affairs aspects of the Fenestration and Glazing Industry Alliance (FGIA). His background is a tapestry of architectural firm work, modular design, as well as residential and commercial fenestration experience. He also spent three years teaching as an adjunct professor. He is experienced in managing technical teams, including employee development, operational strategy, and financial management. He can be reached at ssaffell@FGIAonline.org.