Structural safety of wood decks and deck guards

by Molly Doyle | November 1, 2013 12:20 pm

[1]

[1]by Joseph R. Loferski, PhD, and Frank E. Woeste, PE, PhD

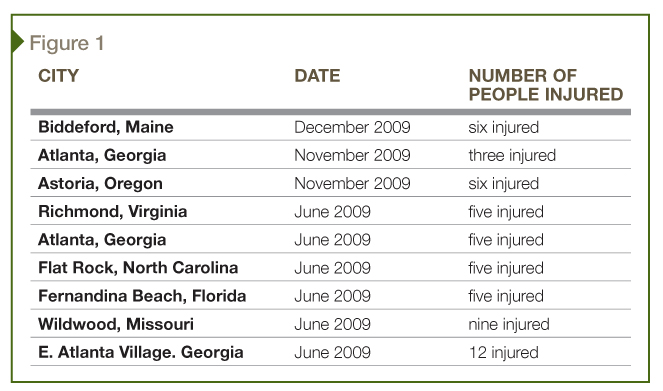

Most residential deck-related accidents are caused by failure of the deck-to-house connection or of the guardrail system, which can cause a person to fall from the deck, resulting in serious injuries or death.

A sample of accident reports is given in Figure 1. Additionally, the authors have partial data dating back to 2001, showing the problem is widespread; accidents occur in nearly every region of the United States. The news reports often state the cause of a catastrophic deck failure was ‘over-loading.’ Based on media reports and the authors’ own investigations, however, many of the subject decks should have safely carried their load without collapsing.

[2]

[2]Why do some decks and guards fail and cause injuries? Several reasons for deck failures have been observed, including inadequate fasteners and connections, corrosion, improper materials, construction defects, and wood decay.

Decks are often designed as a collection of individual parts, rather than as a unified system of interrelated components. For example, the failure of the deck ledger connection to the house may be due to a combination of factors, including no or improper flashing leading to decay in the house band joist, and improper or inadequate fasteners. Guard failure is most commonly caused by failure of the connection of the guard post to the deck, the connection of the rails to the post, or connection of the pickets to the rails. Further, because decks are exterior structures permanently exposed to weather, long-term decay or fastener/connector corrosion is more likely, and can contribute to a failure.

This article specifically addresses residential decks, but multi-family and light commercial decks, balconies, and guards—with more demanding code requirements—can have similar failure modes, making the general concepts quite pertinent. The architect and specifier should exercise great care and diligence when specifying deck or balcony-type structures (and related guards) as they are likely to require expertise in waterproofing specifications and details. (See “Multi-family Balconies[3].”)

Problem overview

Deck collapses and guard failures generally can be traced to designers and contractors who focus on parts and components rather than taking a holistic approach. For example, a through-bolted connection between the guard post and the deck band joist rarely fails. However, the connection of the band joist to the deck joist often uses nails or screws inserted in the end-grain of the joists. Since the guard post is at least 914 mm (36 in.) above the deck surface, it acts as a lever, causing the band joist to ‘peel’ away from the joists.

![Photo of a typical deck attached to house; the circle shows the ledger connection. [CREDIT] Photos courtesy Joseph Loferski](http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-89-2.jpg) [4]

[4]The 2012 International Residential Building Code for One- and Two-family Dwellings (IRC) does not include a prescriptive method or detail for connecting a guard post to a deck substructure. Therefore, many contractors are faced to determine what is needed for a safe guard post connection without any code guidance, except for the vague 890-N (200-lb) concentrated load requirement in IRC.

Specific language and prescriptive details in a future IRC edition on how to make a connection of the guard post to the deck that will safely resist this 890-N load is desperately needed by all parties involved—specifiers, architects, engineers, contractors, home inspectors, and the building code enforcement community.

IRC does contain prescriptive guidelines for bolt and lag screw attachment of deck ledgers to a solid-sawn house-band, based on work by the authors at Virginia Tech University in collaboration with researchers at Washington State University.1[5]

[6]

[6]Design considerations for ledgers

Most often, decks are attached directly to the house using bolts or lag screws that connect the ledger to the house-band. On the other side, the deck is supported by a beam resting on columns bearing on concrete footings as shown in Figure 2.

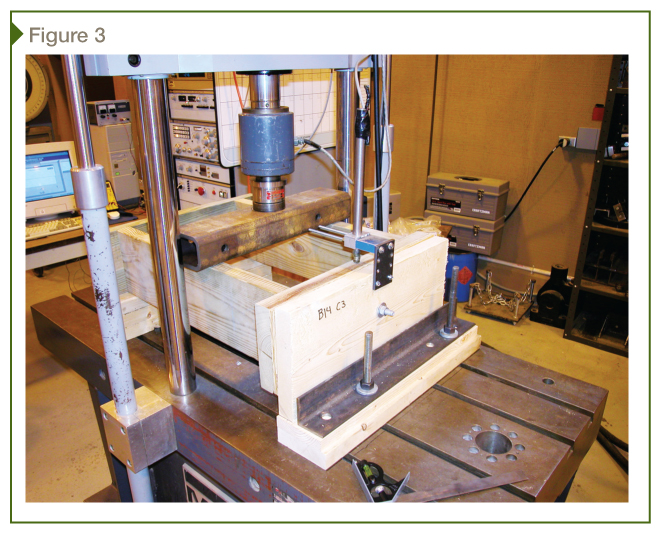

Deck ledger connection tests were conducted to develop bolt and lag screw spacing requirements for various commonly used deck designs.2[7] Figure 3 shows a deck ledger connection being tested for gravity load capacity. The test used a 2×10 (nominal) to simulate the house band and a 2×8 (nominal) pressure-preservative-treated (PPT) member to simulate the deck ledger. Two simulated deck joists were attached to the ledger. The load was applied to the joists until failure. A transducer measured the ledger’s deflection relative to the band joist.

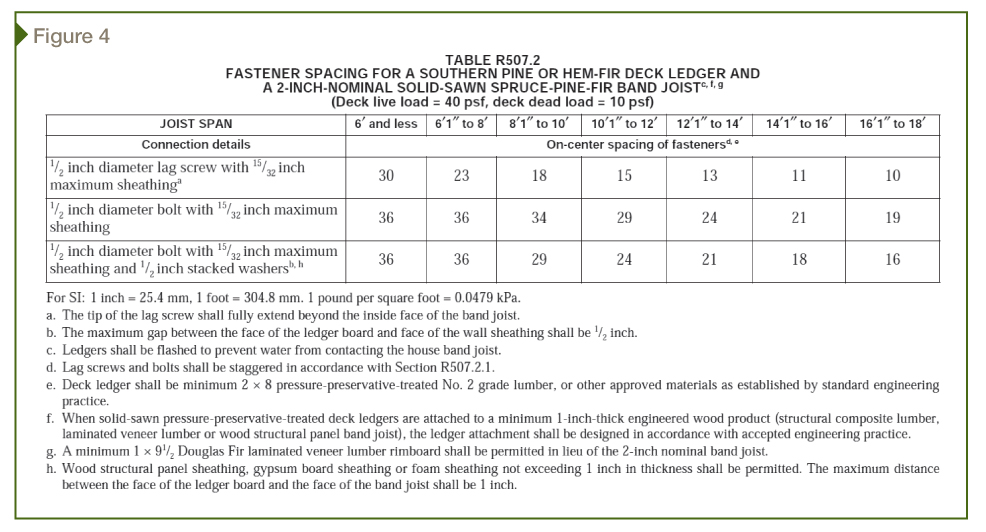

The results were used to compute fastener spacing requirements based on tested capacity of the connection. IRC Table R507.2 (Figure 4) gives the ledger connection requirements, and IRC Section R507.2.1 provides the required placement of bolts or lag screws in the deck ledger connection. All parties involved must closely review the design assumptions and limitations in the caption (e.g. live and dead loads) and footnotes to Table R507.2.1.

Proper screw and bolt installation requirements—American Wood Council’s (AWC’s) National Design Specification (NDS) for Wood Construction with 2012 Supplement—must be followed for the fastener spacing requirements listed in the table.

[8]

[8]Another consideration is the type of lumber and posts used to build the deck. Using alkaline copper quaternary (ACQ) and copper azole (CAB) wood preservatives is now common for deck construction. These preservatives are generally known to be more corrosive to steel fasteners than chromated copper arsenate (CCA) preservatives. Therefore, corrosion-resistant fasteners such as hot-dipped galvanized steel or stainless steel must be used for reliable performance.

Some decay fungi are ‘copper limited,’ meaning they can colonize wood products treated with copper-based preservatives such as ACQ and CAB.3[9] Research has shown even wood treated to ‘ground contact’ treatment retention levels may experience fungal decay.4[10] So, embedding support posts into the ground may not be the best option. To improve deck post longevity, posts should be placed on concrete piers above ground-line and connected with a corrosion-resistant post-connector to the concrete piers. While not necessarily a code requirement, 6×6 (minimum) posts are recommended for aesthetic reasons and are much less likely to undergo severe warp (i.e. bow and twist).

![Typical deck guard system showing posts, rails, and pickets. [CREDIT] Photo courtesy Joseph Loferski](http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-91-300x233.jpg)

Other system considerations include lateral bracing for both house-attached and freestanding decks. In Section R507.2.3 and Figure R507.2.3, IRC includes a prescriptive detail that can be used to meet the code requirements for lateral deck stability. The detail shows a connection from the deck joists to the house joists, and it requires a design load capacity of 6.67 kN (1500 lb). At least two such connectors are required for the deck’s lateral bracing.

Considerations for safe deck guards

A guard is a system of interconnected parts that protects occupants from falling off the deck for whatever reason. Guards are required on residential decks more than 762 mm (30 in.) above ground level. Per IRC, the guard must be 914 mm (36 in.) above the deck surface or, in the case of a bench-guard combination, the guard height must be 914 mm above the bench seating surface.

Wooden guards typically consist of many parts fastened with bolts, screws, or nails. Guard posts are typically stress-rated 4x4s bolted to the deck band joist. Two rails between the posts are usually 2×4 cross sections—one at the top of the post, and the other positioned less than 102 mm (4 in.) above the deck surface. The rails transmit the applied loads to the posts. Pickets between the rails transmit loads into the rails. A typical guard is shown in Figure 5. While not addressed in this article, numerous non-structural requirements for guards are extremely important to child and life safety, and are covered by IRC.

![Tests of guardrail post to deck connections at Virginia Tech demonstrated a safety factor of 2.5 on the code required load of 890 N (200 lb). [CREDIT] Photo courtesy Frank Woeste](http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-91-2.jpg) [11]

[11]The well-known building code requirement for guards is 890 N (200 lb) concentrated load applied in any direction to the top of the guard system. As stated earlier, a critical connection is the guard-post-to-deck structure. Laboratory tests of 4×4 posts loaded at 914 mm above the deck surface demonstrated the large force that is produced at the base of the post. Some commonly observed post connection details that rely on lag screws alone have been tested at Virginia Tech. For one tested case, the guard post separated from the deck band joist at a load level approximately 25 percent of the code requirement.

Due to the ‘lever’ action, the band joist can also separate from the joist ends because it is inadequately attached with nails or screws installed into the end grain of the joists.5[12] This connection detail is weak because the fasteners used to attach the band to the joists are loaded in withdrawal from end grain. The guard post is through-bolted to the deck band joist, so it appears to be a strong connection—however, it can fail at very low loads compared to what is required by the code.

Laboratory tests of 4×4 stress-rated guard posts (Figure 6) demonstrated steel connectors can adequately transmit loads produced by the code-required concentrated load on the top of the guard into the deck joists.

Figure 7 shows a schematic of a post-to-deck attachment using one or two connectors. For guardrails running perpendicular to the joists, the post can be attached directly to the connector if the post location is adjacent to a joist. Otherwise, two connectors are used to attach the band to joists, and the guard post is attached to the band with bolts between the connectors.

![Schematic of post-to-deck attachment with connectors. [CREDIT] Image courtesy American Wood Council](http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-93.jpg) [13]

[13]

![Severely weakened post notched at the bottom. [CREDIT] Photo courtesy Joseph Loferski](http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-94.jpg) [14]

[14]

For all fasteners and connectors used in exterior environments, corrosion is an issue since it reduces connection strength. Therefore, at a minimum, code-recognized and approved corrosion-resistant metals or coatings must be employed in guard construction. Stainless steel fasteners and connectors are recommended by AWC DCA 6, Prescriptive Residential Deck Construction Guide, for guard systems exposed to saltwater or coastlines.7[16]

Notes

1 For more, see the authors’ co-written article with D. Carradine and D. Bender in the May 2008 issue of Structure Magazine, “Lessons Learned: Residential Deck Ledger Connection Testing and Design.” Visit www.structuremag.org/Archives/2008-5/C-LessonsLearned-DeckLedger_Carradine-May08.pdf[17]. (back to top[18])

2 See the authors’ co-written article with R. Caudill, T. Platt, and Q. Smith, “Load-tested Deck Ledger Connections,” in Journal of Light Construction (vol. 22, no. 6). Visit www.jlconline.com/Images/Practical%20Engineering_%20Load-Tested%20Deck%20Ledger%20Connections_tcm96-1098165.pdf[19]. (back to top[20])

3 See the article by Loferski et al, “Brown-rot Decay of ACQ and CA-B Treated Lumber,” in Forest Products Journal (vol. 57, no. 6). (back to top[21])

4 Ibid. (back to top[22])

5 See the authors’ co-written article with D. Albright and Caudill, “Strong Rail-post Connections for Wooden Decks,” in Journal of Light Construction (vol. 23, no. 5). Visit www.jlconline.com/lumber/strong-rail-post-connections-for-wooden-decks.aspx[23]. See also the co-written article with Albright from the July 2007 Structure Magazine, entitled “Tested Guardrail Post Connections for Residential Decks: Lessons Learned.” Visit www.structuremag.org/Archives/2007-7/C-LL_Wood_Post_Connections_by_Loferski.pdf[24]. (back to top[25])

6 Ibid. (back to top[26])

7 See Woeste’s article, “Safe and Durable Coastal Decks,” from Coastal Contractor (vol. 5, no. 2). Visit www.coastalcontractor.net/pdf/2008/0803/0803safe.pdf[27]. (back to top[28])

Joe Loferski, PhD, is a professor of sustainable biomaterials at Virginia Tech. He has an international reputation and experience in the areas of performance of wood and wood composites in buildings, along with the preservation of historic wood buildings. Loferski can be reached at jloferski@vt.edu[29].

Frank Woeste, PE, PhD, is an adjunct professor of sustainable biomaterials at Virginia Tech. He is a wood construction and engineering consultant, and a past contributor to The Construction Specifier. Woeste can be contacted via e-mail at fwoeste@vt.edu[30].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/bigstock-Beachfront-Outdoor-Living-Home-3004706.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-89.jpg

- Multi-family Balconies: http://www.constructionspecifier.com/masterformat/structural-safety-of-wood-decks-and-deck-guards-multi-family-balconies/

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-89-2.jpg

- 1: #note1

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-90.jpg

- 2: #note2

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-90-2.jpg

- 3: #note3

- 4: #note4

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-91-2.jpg

- 5: #note5

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-93.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2014/05/CS_November2013_HR-94.jpg

- 6: #note6

- 7: #note7

- www.structuremag.org/Archives/2008-5/C-LessonsLearned-DeckLedger_Carradine-May08.pdf: http://www.structuremag.org/Archives/2008-5/C-LessonsLearned-DeckLedger_Carradine-May08.pdf

- top: #note8

- www.jlconline.com/Images/Practical%20Engineering_%20Load-Tested%20Deck%20Ledger%20Connections_tcm96-1098165.pdf: http://www.jlconline.com/lumber/practical-engineering--load-tested-deck-ledger-connections.aspx#

- top: #note9

- top: #note10

- top: #note11

- www.jlconline.com/lumber/strong-rail-post-connections-for-wooden-decks.aspx: http://www.jlconline.com/lumber/strong-rail-post-connections-for-wooden-decks.aspx

- www.structuremag.org/Archives/2007-7/C-LL_Wood_Post_Connections_by_Loferski.pdf: http://www.structuremag.org/Archives/2007-7/C-LL_Wood_Post_Connections_by_Loferski.pdf

- top: #note12

- top: #note13

- www.coastalcontractor.net/pdf/2008/0803/0803safe.pdf: http://www.jlconline.com/coastal-contractor/coastal-resources-safe-and-durable-coastal-decks.aspx

- top: #note14

- jloferski@vt.edu: mailto:%20jloferski@vt.edu

- fwoeste@vt.edu: mailto:%20fwoeste@vt.edu

Source URL: https://www.constructionspecifier.com/structural-safety-of-wood-decks-and-deck-guards/