1.1 When field installed SSG is necessary

In some limited situations, field glazing four-sided SSG is the only viable option. Small-scale field installations of just a few IGUs resulting from impact-related glass breakage or construction leave-out panels on new construction projects is one of the most common. The need for large-scale field installations of hundreds of IGUs can result from global material defects, IGU batch failures, and whole-façade energy or aesthetic upgrades. In either case, the project teams for a new construction project or a façade upgrade should follow the same design and construction framework to achieve a predictable outcome.

2. Designing for better outcomes

Designing with field reglazing in mind can mitigate risk to the owner, designer, and contractor. This section will cover the calculation methods and design principals professionals can use to achieve better quality outcomes.

2.1 Characteristics of SSG design

The ability of an SSG installation to satisfy specified performance criteria is based on five primary characteristics:

- Material strength

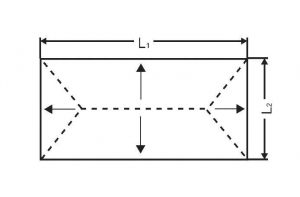

- Joint geometry (i.e. structural bite width of silicone to glass and frame, and joint thickness)

- Continuity

- Cure

- Adhesion

Both design and workmanship affect these primary characteristics. This section discusses ways for the design professional to influence design-related characteristics (i.e. material strength and joint geometry as calculated) through appropriate planning of the façade system and sizing of the SSG joints. Discussed later will be workmanship related issues and how the design professional can influence workmanship related characteristics (i.e. sealant continuity, cure, adhesion, and joint geometry as installed) through specification of appropriate sealant, installation methods, and a robust quality control and quality assurance program.

2.2 Impact of glazing system design on SSG

The design of field installed SSG relies heavily on the original design of the existing framing system. Existing system constraints such as a narrow substrate for sealant bite, limited access for sealant installation, and lack of clear locations for mechanical attachment of temporary clips to retain glazing during sealant cure are often difficult to overcome and will further challenge the execution of a field SSG installation. Likewise, glazing system design that incorporates progressive features such as toggle-holds for temporary stops or conservative joint sizes to receive larger SSG bite widths can greatly improve the success of field SSG installation, or in the case of a framing system that can receive toggle-style cassette systems, fully eliminate the need for field-installed SSG.

To the extent possible, the initial design should provide unimpeded access to the perimeter of the SSG joint to allow for application of sealant from the building interior. Often a faux shadow box, blinds, or any number of other spandrel conditions limit access to the SSG joints, forcing the field installer to apply sealant from the exterior at the head of vision lites and at spandrels. Offsetting the blinds or limiting the faux shadow box height can allow for better access.

the installers shall be trained in the proper installation of dow 795 structural silicone