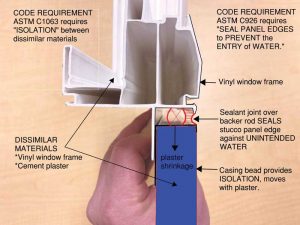

These word selections have caused endless misunderstandings for both designers and stucco craftsmen. The precedent document to ASTM C1063 is ANSI A42.2-1971, Portland Cement and Portland Cement-Lime Plastering Exterior (Stucco) and Interior, which states, “where plaster abuts unplastered construction, a separation shall be provided, such as a casing bead or trowel cut.” The ‘trowel cut’ from 1971 is the ‘V-groove’ of today, and ‘unplastered construction’ from 1971 is ‘dissimilar materials’ today. A metal or nonmetallic casing bead is an integral part of the stucco cladding system, which includes lathing, lathing accessories, and portland cement-based plaster. The metal or nonmetallic casing bead is not a ‘dissimilar material’ as related to the stucco cladding, even though it is a different material from the portland cement-based plaster. It is ‘of the stucco’ as a component of the lathing and plaster system. Window, door, louver wall openings, and at piping, conduit, and similar conditions such as utility penetrations are dissimilar materials from the stucco system, which also require separation from the stucco.

Both a casing bead and a trowel cut may define the stucco panel edge. ASTM C1063 also requires a casing bead or V-groove be installed for the purpose of avoiding the transfer of structural loads to the plaster cladding.

Lastly, ASTM C1063 requires a 10 mm (0.38 in.) gap between the casing bead and the penetrating elements.

Stucco thickness requirements in ASTM C926

Stucco thickness requirements are specified in ASTM C926, Standard Specification for Application of Portland Cement-Based Plaster, and an important primary function of the casing bead is to function as a screed or ground to aid the plaster craftsman in achieving required stucco thickness. The use of casing beads allows the plasterer to gauge the plastering application using the screeds to achieve a nominally uniform plaster thickness, which aids in a durable plaster application and reduced cracking.

ASTM C926 notes another primary function of the casing bead is to assist in the “sealing or caulking of V-grooved, exposed ends, and edges of stucco panels exterior work to prevent the entry of water.” The casing bead as installed along stucco panel edges functions as a surface upon which to adhere sealant between the stucco panel edge and the adjacent unplastered construction. Sealant can be designed and applied to adhere to either the casing bead at the ground surface, or at an extended capture flange surface.

A great overview; I wish it had been available when I became an architect, or even later, when I became a specifier!

I am an owner builder in the San Diego area. I would like to know the casing manufacturers of the casing types that were discussed on the last page of your article

Al’s Can you refer me to or provide a spec that I can use in the bid process.