To summarize, the stucco application will have panel edges abutting unplastered construction using either casing beads or V-grooves, where a 10 mm wide gap is formed at the panel edges. What to do with the gap? ASTM C926 explains how installers must “seal V-grooves, exposed ends and edges of plaster panels or exterior work to prevent the entry of water.” The sealed panel edge joint is required for the basic functional need to keep water out of the wall system, which otherwise may cause significant concealed damage if not sealed. The single most important characteristic to remember for anything portland cement-based is how it shrinks as it cures, and this shrinkage creates gaps at the adjacent unplastered construction. These gaps, which may look small, can allow a significant volume of water to bypass the stucco panel edge and collect within the wall assembly, especially during a wind-driven rain event. Sealing gaps prevents entry of excessive water and allows differential movement between the stucco and dissimilar material. This requirement exists in any jurisdiction where the local building code adopts and references the ASTM International stucco standards.

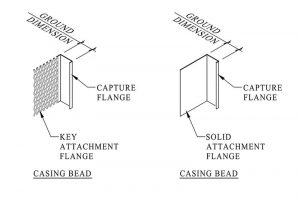

Casing bead specifications from ASTM C1861

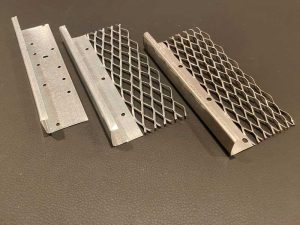

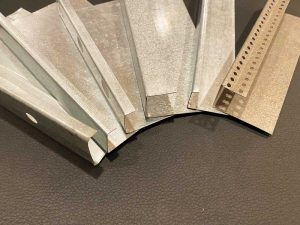

It should come as no surprise to discover not all casing beads are alike. ASTM C1861, Standard Specification for Lathing and Furring Accessories, and Fasteners, for Interior and Exterior Portland Cement-Based Plaster, defines, describes, and illustrates the elements of typical casing beads. A casing bead is defined as a “lathing accessory used as a screed to assist in cement plaster thickness control; to separate cement plaster from dissimilar materials, loadbearing members, and penetrating elements; and to provide an edge, end, or termination for a cement plaster panel area.” ASTM C1861 describes and illustrates the essential elements of a casing bead as including an attachment flange, either of the solid flange or key flange type; a ground dimension, which assists in achieving the required plaster thickness; and a capture flange. The capture flange folds back onto the outermost finished surface of the plaster as a visual cover over the shrinkage gap which so often occurs. How the stucco finish coat terminates at this capture flange will determine how clean the edge of stucco will look and perform—cracking and spalling of the thin edge of stucco is common at capture flanges.

Each of these three elements can vary for longer attachment flanges and a range of ground dimensions (for plaster thickness). The capture flange can be minimal for reduced visual impact or wider to function as a surface to receive sealant when plaster is perpendicular to an adjacent surface, such as at recessed wall opening returns into window frames. Perforations may be provided if the casing bead is configured correctly and is designed to provide a drainage function at the base of a panel. Many lathing accessories, including casing beads, come in a range of metal materials—galvanized steel, zinc alloy, stainless steel, galvalume, and others—as well as nonmetallic polyvinyl chloride (PVC), which is typically used in coastal environments.

A great overview; I wish it had been available when I became an architect, or even later, when I became a specifier!

I am an owner builder in the San Diego area. I would like to know the casing manufacturers of the casing types that were discussed on the last page of your article

Al’s Can you refer me to or provide a spec that I can use in the bid process.