The panel edge joint: Function, durability, and aesthetics

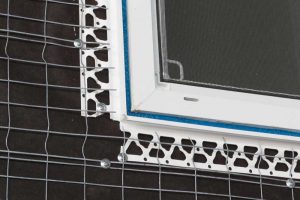

It is entirely appropriate and helpful to think of the casing bead and the required sealed gap located adjacent to unplastered construction as a panel edge joint where the stucco cladding begins and ends. Understanding this assembly as a functional, purposeful panel edge joint—and not just an installed casing bead and sealant—is useful and beneficial to those who design or construct stucco claddings. It encourages one to understand the function of the joint as an assembly and not just focus on its individual parts. Without a casing bead and sealant, when the plaster shrinks away from the adjacent unplastered construction, a resulting unsealed gap often develops. Without a casing bead, required plaster thickness cannot be verified. Water can penetrate the unsealed gap, and when this happens, there may be a debate about who owns the gap. The adjacent trades will blame the other, and vice versa, for any resulting water penetration and concealed damage. Understanding the assembly of a casing bead and sealed gap as a panel edge joint provides a clear demarcation of work between different adjacent trades.

The problem with stucco keys

Manufacturers of metal, PVC, and wood windows and doors each have versions of stucco keys integrated with their products. Keying the stucco to dissimilar material (i.e. the window frame) is used to eliminate the code-required, water-resistant isolation mechanism (the sealed casing bead panel edge joint) codified in the stucco industry standards as necessary “to prevent the entry of water” around windows or door frames. For this reason, they do not meet the requirements of an “other suitable means.” The concept is misguided, is an attempt to legitimize incorrect practices and violations of the code, and leaves the most vulnerable locations to water entry unprotected.

The water resistivity performance requirement in ASTM C926 is “to prevent the entry of water,” which is clearly stated and codified. Portland cement-based plaster will inevitably shrink away from windows and doors, creating a gap for water infiltration. Further, stucco keys in dissimilar components are not defined or approved as lathing accessories in either ASTM C1063 or ASTM C1861. They are ‘of the window or door’ and not ‘of the stucco.’ As an integral element of the window frame, a stucco key is not capable of providing the required separation between the window frame and the plaster edge. Stucco keys are a disservice to the stucco industry, and to building owners who suffer concealed water damage resulting from this indefensible practice.

A great overview; I wish it had been available when I became an architect, or even later, when I became a specifier!

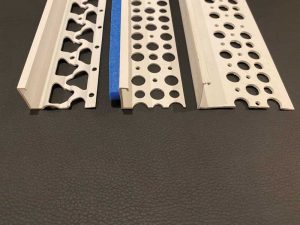

I am an owner builder in the San Diego area. I would like to know the casing manufacturers of the casing types that were discussed on the last page of your article

Al’s Can you refer me to or provide a spec that I can use in the bid process.