Sustainable, high-performance design with natural stone

Photos courtesy David Hughes, MEIAI, RIBA

Sustainable characteristics of stone (and LEED points to consider)

Stone can also contribute to LEED points in several different credits including Sustainable Sites (SS), Energy and Atmosphere (EA), Materials and Resources (MR), Integrative Process (IP), and Innovation (IN). Testing and documentation are required as part of the certification process.

One should explore the use of stone early in the design process to ensure the material’s role in high-performance design is understood and valued by all team members. This also allows time for any required testing or documentation to be requested and submitted to earn those valuable points.

Sustainable Sites

For SS Credit 5, Heat Island Reduction (Option 1: Non-roof Measures), light-colored natural stone, with the required solar-reflective index (SRI), can be used on such features as landscaping walls, stair treads, and pavement. (This is done per ASTM E1980, Standard Practice for Calculating Solar Reflectance Index of Horizontal and Low-sloped Opaque Surfaces.) If the SRI test has not already be done by a fabricator or stone supplier, designers may request it to determine whether the stone they are interested in using on a project would qualify.

Energy and Atmosphere

Stone can play a role in achieving EA Credit 2, Optimize Energy Performance (Option 1: Whole-building energy simulation and Option 2: Prescriptive compliance). The material has the ability to store heat and slowly release it. This inherent thermal mass property has a positive impact on indoor ambient air temperature and, as a result, energy efficiency.

Materials and Resources

Due to the durability, recyclability, and regional availability of stone, the material’s use can potentially contribute to the earning of several credits in the Materials and Resources category. They include:

- MR Credit 1, Building Life Cycle Impact Reduction (Option 1: Historic Building Reuse, Option 2: Renovation of Abandoned or Blighted Building, and Option 3: Building and Material Reuse);

- MR Credit 2, Building Product Disclosure & Optimization (Option 1: Environmental Product Declaration and Option 2: Multi-attribute Optimization);

- MR Credit 3, Sourcing of Raw Materials (Option 1: Raw Material Source & Extraction Reporting and Option 2: Leadership Extraction Practices);

- MR Credit 3, Material Ingredients (Option 1: Material Ingredient Reporting, Option 2: Material Ingredient Optimization, and Option 3: Product Manufacturer Supply Chain Optimization); and

- MR Credit 5, Construction & Demolition Waste Management (Option 1: Diversion and Option 2: Reduction of Total Waste Material.

Integrative Process

Applying the integrative process to a project where stone supports the reduction of energy and water use may be an option for IP Credit 1, Energy-related Systems and Water-related Systems.

Innovation

Use of natural stone may contribute to exceptional performance in areas such as life cycle cost and durability, mold resistance, and improved indoor air quality (IAQ).

Seeking multiple solutions and benefits using stone

High-performance buildings are often expected to last 50 to 100 years (or longer), remaining aesthetically pleasing over time. Natural stone has long been chosen for its wide range of aesthetics due to color, pattern, grain, texture, and other natural variations. With new options for fabricating and finishing, and new stone choices in the marketplace, the visual options have been greatly expanded; they can be applied to any type of project of any scope, scale, or location.

Stone improves overs time and its aged patina resonates with aesthetic values that have no expiration. However, a client or designer’s aesthetic values can also have an impact on the environmental aspects of a project. For instance, if only a portion of a stone block’s grain, texture, or color is considered desirable, the remaining stone can end up as waste. By finding creative uses for that remaining material, or expanding the aesthetic range of the stone that is acceptable for the project, waste can be reduced or even eliminated.

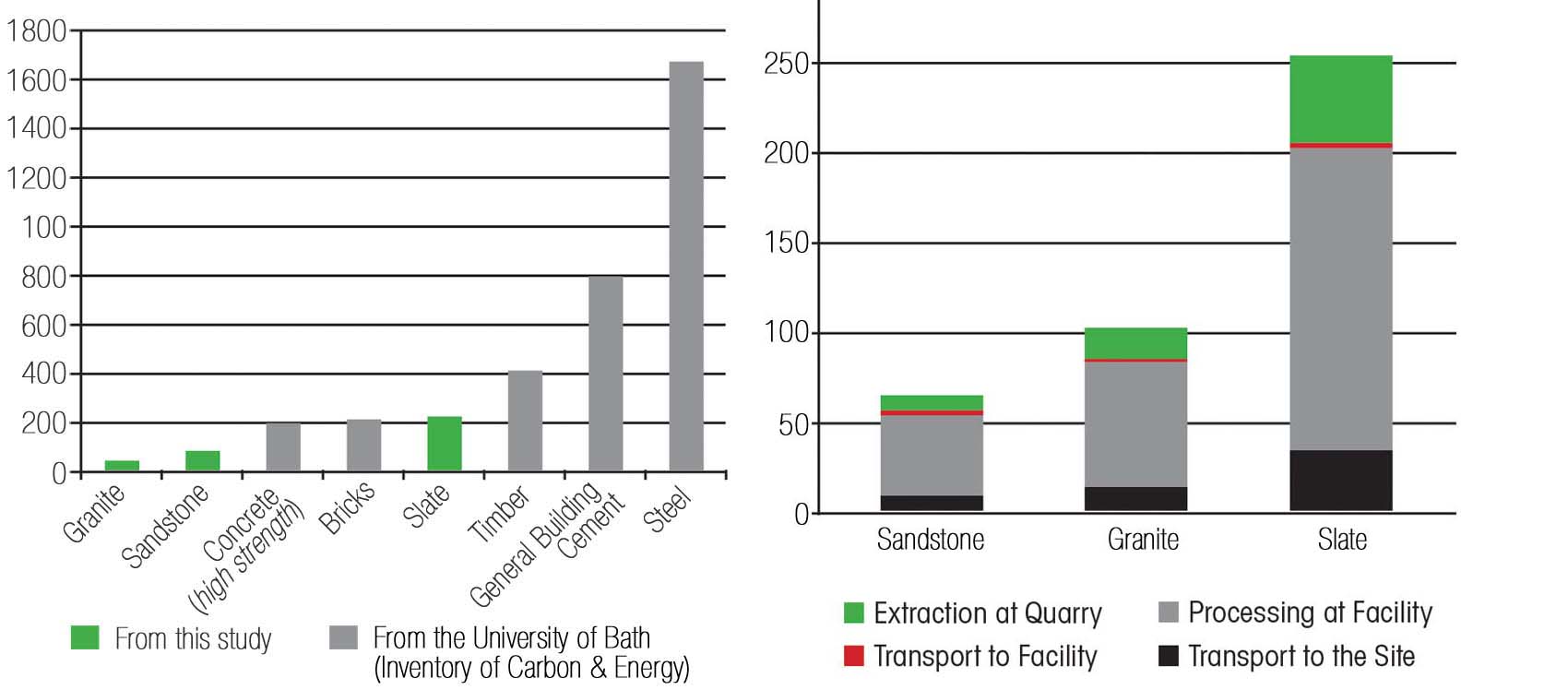

Stone does not off-gas and is mold-resistant, contributing to IAQ levels for healthy, productive environments. In many cases, natural stone can be sourced or found locally, reducing carbon emissions from transporting materials from greater distances. It is important to weigh the decision to use local materials over the long term. Research has shown the largest impacts during the life cycle of stone do not occur during the transportation stage, but during the processing stage (Figure 1). If the design life of the building is 75 to 100 years, then the transportation impacts only occur once during that period, compared to a material needing replacement every seven to 10 years.

Image courtesy Stone Federation Great Britain