Tensile architecture: Where substance meets style

by arslan_ahmed | February 16, 2024 10:00 am

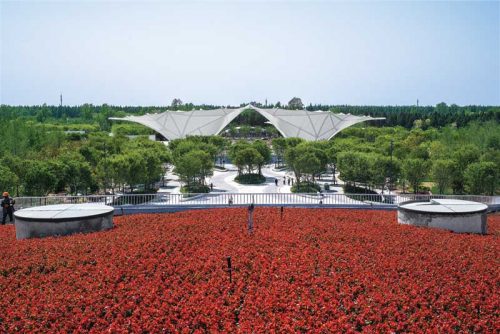

[1]

[1]By David Peragallo

Tensile architecture, also known as tensile structures or fabric architecture, is becoming a popular choice for applications such as stadiums, airport hubs, train and bus stations, exhibition halls, event pavilions, and temporary structures such as festival tents. This structural design approach uses tension forces to create stable and visually striking structures.

Tensile architecture stands at the forefront of contemporary design, offering architects and designers a realm of possibilities that merge functionality with aesthetic innovation.

Design considerations

Successful tensile architecture demands a holistic approach that considers aesthetics, functionality, environmental factors, and structural integrity. Tensile structures often create unique spatial experiences, whether in public spaces, commercial buildings, or recreational areas. This is why collaboration between architects, structural engineers, and other specialists is essential, to navigate its technical intricacies and bring forth innovative and enduring tensile structures.

One of the key benefits of tensile architecture is its ability to integrate form and function. This means when striking a balance between aesthetics and functionality, designers must consider how their work will influence the experience of the users or occupants.

Though boasting remarkable environmental adaptability, climate analysis is vital for a successful tensile design. Understanding the local climate is crucial for resiliency, as wind and snow loads, temperature variations, and exposure to sunlight impact the structure’s performance. Computational tools and simulations can be used to help predict environmental effects.

Another important consideration is identifying opportunities to integrate sustainable features. Tensile structures can facilitate natural ventilation, daylighting, and rainwater harvesting. Further, optimal orientation and the use of eco-friendly materials used to build tensile structures contribute to sustainability.

From a structural engineering standpoint, load distribution and integration of compression elements should be carefully considered. Tensioned elements must distribute loads effectively to ensure structural stability. The design should account for factors such as wind, snow, and dead loads. Collaborating with structural engineers is essential to ensure the structure can withstand these loads. Further, incorporating compression elements, such as masts or columns, provides additional support. The combination of tension and compression elements enhances the overall structural integrity.

When it comes to the choice of material, current advancements allow for a wide variety of membranes, cables, and connections. Specifiers should choose membrane materials based on their mechanical properties, durability, and aesthetic characteristics. Polytetrafluoroethylene (PTFE), polyvinyl chloride (PVC), ethylene tetrafluoroethylene (ETFE), structural, transparent, fluorinated envelope (STFE), and other high-strength fabrics offer different advantages. They should also consider factors such as translucency, color options, and resistance to environmental degradation. High-strength cables, usually made of materials such as steel, are critical components. Understanding the tensile strength, elasticity, and corrosion resistance of these materials is vital in selecting the appropriate type and diameter. To meet durability requirements, select materials that withstand environmental conditions over time. UV resistance, corrosion resistance, and resistance to wear and tear are crucial for ensuring the longevity of the tensile structure.

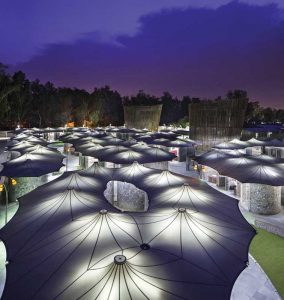

[2]

[2]Skilled architects and planners will consider how their project integrates with its surroundings. Ideally, thoughtfully designed tensile structures will complement the architectural context of their surroundings. Whether in urban landscapes or natural settings, the design should enhance, rather than clash with, the existing environment. Similarly, if the tensile structure is part of a larger architectural project, the design team should ensure seamless integration with other elements. This includes considerations for pathways, entrances, and adjacent buildings.

As with any project, cost considerations should be considered early on in the design phase. A comprehensive life cycle cost analysis (LCCA) will include maintenance, repairs, and potential replacements to make informed decisions. While tensile structures may offer initial cost savings in terms of materials, consider the long-term costs and explore ways to optimize expenses without compromising on quality. Practicing value engineering will help project teams find cost-effective solutions while maintaining the core functionalities and aesthetics of the design.

Code compliance and safety should also be a top priority as adherence to local building codes and regulations is non-negotiable. Ensure the design meets safety standards, fire codes, and structural requirements. Consultation with local authorities and code experts is imperative. Moreover, considering accessibility standards is fundamental in ensuring the structure accommodates people of varying abilities. This includes provisions for ramps, elevators, and other accessibility features.

Before full-scale construction, it is highly encouraged to conduct prototype testing. This involves creating a scaled-down version of the structure to validate design concepts, assess material performance, and identify potential issues. Prototype testing contributes to the refinement of the final design. There should also be considerations for future maintenance. By developing a comprehensive maintenance plan that includes regular inspections, cleaning, and necessary repairs, projects benefit from an extended lifespan and prevent unexpected issues.

When built with flexibility and adaptability in mind, design enables future expansions or modifications. Tensile structures are remarkably adept at adapting to changing needs, making them versatile solutions for evolving spaces. This also allows for the exploration of opportunities to integrate smart technologies into the design. This may include sensors for environmental monitoring, automated shading systems, or dynamic lighting solutions.

Installation tips

The successful installation of tensile architecture demands a meticulous and collaborative approach. From pre-installation engineering to long-term maintenance planning, each step contributes to the success of the project. By adhering to best practices, addressing site-specific challenges, and prioritizing safety, architects and construction teams ensure the seamless integration of innovative tensile structures into the built environment.

One crucial step in the installation process is pre-installation engineering, which requires a thorough analysis of the site and environmental conditions before installation. This includes geotechnical studies to understand soil conditions and comprehensive climate assessments to anticipate any challenges posed by weather conditions. Teams should also use advanced structural simulation tools to ensure the tensioned elements are installed with the correct levels of tension. Simulations can help identify potential issues and optimize the design for site-specific conditions.

[3]

[3]Assessing these challenges allows the project team to adapt to local conditions and mitigate the structure’s environmental impact. Each site presents unique challenges, from wind direction and seismic activity to local regulations. Implementing measures to mitigate the environmental impact during installation may include erosion control measures, waste management strategies, and considerations for protecting nearby ecosystems.

Tensioning, alignment, and leveling of tensile systems should be approached with engineering precision. Achieving the correct tension in cables and membranes is essential for the structural integrity of tensile architecture. Design teams must work closely with structural engineers for accurate tensioning, taking into account factors such as wind loads and material properties. The precise alignment and leveling of structural elements are of utmost importance, as even slight deviations can impact the overall stability and aesthetics of the structure. Laser-guided tools and careful measurements are essential for achieving accuracy.

When handling membrane materials, it is important to remember they are often sensitive to scratches and abrasions. Installers should use proper handling techniques and protective coverings during installation to prevent damage, as well as to avoid contact with sharp objects or abrasive surfaces. Installation activities should also be planned with consideration for weather conditions. High winds, rain, or extreme temperatures can impact both the installation process and the integrity of materials. Temporary weather protection measures must be taken as needed.

A multidisciplinary collaboration

Between architectural, engineering, and construction teams, regular communication and coordination ensure the installation aligns with the design intent and engineering specifications. The construction team must be adequately trained in the unique requirements of tensile architecture installation and be familiar with tensioning techniques, material handling, and safety protocols.

For quality control (QC) purposes, a system for continuous monitoring during installation is recommended. Regular checks on tension levels, alignment, and other critical factors help identify and address issues promptly. Regularly conducting load testing to validate the structure’s performance under anticipated conditions is also a must. This includes testing the structure’s response to wind loads, snow loads, and other environmental factors.

Prioritizing safety during installation includes protocols for fall protection measures, equipment safety checks, and emergency response plans. Safety teams must conduct regular safety training sessions for all personnel involved, and strictly adhere to all safety regulations. Regular inspections by safety officers can help identify and rectify potential hazards and assist the team in staying compliant with local safety regulations and industry standards.

To assist with the post-construction records, it is essential to maintain detailed as-built documentation. Accurate drawings and documentation aid in future maintenance and modifications, providing a reference for any adjustments or expansions. Keeping meticulous records of installation activities, such as inspections, material deliveries, and any deviations from the original design, is invaluable for project management and quality assurance (QA).

[4]

[4]Conducting a thorough inspection after installation is complete includes visual inspections, structural assessments, and performance evaluations under varying conditions. Identifying any defects or issues during the final inspection—and promptly rectifying them—is valuable for addressing potential problems early on, preventing long-term damage and ensuring the structure meets design specifications. Understanding the importance of proactive maintenance in enhancing the longevity of the structure, architectural teams should provide training for maintenance personnel after the installation so they have the necessary skills to conduct routine inspections and address minor issues.

Materials and mechanics properties of tensile architecture

The material and mechanical properties of tensile architecture materials are diverse and interconnected. A holistic understanding of these properties is essential for architects and designers to make informed decisions during design, construction, and maintenance. Balancing durability, aesthetics, and performance is key to the success of tensile structures in various applications.

Membrane materials

- PTFE membranes are known for their high tensile strength, flexibility, resistance to UV radiation, and non-combustible properties. They exhibit low friction and excellent chemical resistance. In addition, PTFE membranes offer good light transmission, providing a balance between natural daylighting and solar heat reduction.

- PVC membranes are characterized by their durability, fire resistance, and cost-effectiveness. They offer good tensile strength and are suitable for a range of climates. PVC membranes can be translucent, allowing for diffused natural lighting, but they may have slightly lower translucency compared to other materials.

- ETFE membranes are lightweight, transparent, and resistant to environmental degradation. This film is often used for large-span structures when combined with a structural cable system or designed as a multilayer cushion pressurized by an inflation unit. Highly transparent, ETFE allows for abundant natural light, making it suitable for applications where visibility is a key consideration.

- STFE is a revolutionary solution for creating light-filled spaces. Its polyarylate (PAR) mesh provides structural strength to large free-span designs, minimizing the need for additional supporting structure. With light transmission of 50 percent, STFE provides an outdoor feeling and enables grass and other plants to grow.

Cables and tendons

- Steel cables: Widely used for their high tensile strength, durability, and resistance to corrosion. Steel cables come in different types, such as galvanized or stainless steel, and may be chosen based on environmental conditions. Steel exhibits elastic deformation, allowing it to return to its original shape after undergoing stress.

Connectors and fasteners

- Aluminum and stainless-steel connectors: Connectors and fasteners, typically made of aluminum or stainless steel, must exhibit high strength and corrosion resistance to ensure the overall stability of the structure. The connectors should be designed to avoid abrasion or damage to membrane materials during tensioning or in response to environmental forces.

[5]

[5]Coatings and surface treatments

- UV-resistant and anti-soiling treatments: UV-resistant coatings such as PVDF, PVC, and PTFE on membrane materials protect against degradation caused by prolonged exposure to sunlight and prevent the accumulation of dirt and pollutants on membrane surfaces. This enhances the durability of the structure, ensuring it withstands weathering and frequent cleaning without compromising its effectiveness. The effectiveness and longevity of these coatings contribute to the lifespan of the tensile structure.

Fire performance

- Fire-retardant treatments: Fire-retardant treatments for membrane materials are essential for compliance with building codes and ensuring the safety of occupants. Understanding how fire-retardant treatments may impact the mechanical properties of materials is crucial to maintaining the required structural performance.

Thermal properties

- Insulating properties: Some membrane materials may have inherent insulating properties, contributing to energy efficiency in the building, or a double membrane might be used as well. Understanding these properties is crucial for climate control. The balance between translucency and thermal properties influences the comfort levels inside the structure.

Dynamic behavior

- Wind response: Tensile structures should be designed to respond to wind loads. Understanding the wind-induced vibrations and the dynamic behavior of materials is crucial for structural stability. Conducting wind tunnel testing during the design phase helps predict and mitigate any adverse effects of wind-induced movements.

- Seismic response: In seismic-prone regions, understanding the dynamic behavior of tensile structures under seismic forces is crucial. The materials must exhibit resilience and the ability to dissipate seismic energy.

Conclusion

Tensile architecture stands as a testament to the evolution of design in the architectural landscape. With a focus on meticulous design considerations, precise installation, and adherence to industry standards, architects and designers can unlock the full potential of tensile structures. By embracing the technical nuances of this innovative approach, professionals can push the boundaries of what is achievable in modern construction, creating structures that captivate the eye while standing the test of time.

Author

Author

Throughout his professional career, David Peragallo has created, organized, and led the implementation of projects for high-performance architectural textiles. Before joining Serge Ferrari Group in 2021, Peragallo served as specification and regional sales manager for Verseidag-Indutex GmbH, a German-based supplier of architectural textiles.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Fig1_Gate-One-of-China-Flower-Expo-2021-.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Fig2_LV-shop-in-Taikooli-Foreshore-Shangh.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Fig3_Dilli-Hatt-Market-place.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Fig4_Mpavilion-2022-STFE-Soltis-86-Australia.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2024/02/Fig5_Olympic-Golf-Course-Rio-2016-Sede-do-Campo-Olimpico-de-Golfe.jpg

Source URL: https://www.constructionspecifier.com/tensile-architecture-where-substance-meets-style/