The Automatic Choice: How and when to select power-operated doors

by Katie Daniel | July 14, 2017 9:56 am

[1]

[1]by Michael Tierney

Selecting the best type of automatic door for a particular building can be challenging for any specifier, as it requires several considerations, ranging from desired traffic flow and expected user types to aesthetic preferences, space available, and whether the door meets state and federal codes. This means when it comes to selecting automatic doors for hospitals, airports, hotels, shopping malls, retail stores, government and office buildings, and colleges and universities, it is never a matter of ‘one size fits all.’ In fact, it may be surprising how many choices are available.

The decision to specify and install automatic doors should primarily be determined by the types of users and the quantity of people expected to enter and exit the facility on a regular basis. Such doors are typically used in facilities where users may include persons with disabilities, the elderly, or others who may have trouble opening the door manually (e.g. a shopper with multiple bags or someone pushing a shopping cart or stroller).

There are three major types of automatic—or power-operated—pedestrian doors:

- swinging;

- sliding; and

- folding.

Power-operated revolving doors may also be considered.

In order to guarantee the proper type of automatic door is selected, the following questions must be asked:

How much space do I have?

The facility layout is the first thing to consider when deciding which type of door to install. For example, swinging, sliding, and revolving doors require more wall and lobby space, making them good options for facilities with larger entrances. Automatic folding doors, on the other hand, require minimal space to install, yet still provide an ample amount of clear door opening. This makes them a great space-saving option.

American National Standards Institute/Builders Hardware Manufacturers Association (ANSI/BHMA) A156.10, Standard for Power-operated Pedestrian Doors, defines clear openings as follows for the purpose of sizing activating and safety zones. Applicable building codes pertaining to means of egress should be consulted for clear-width requirements.

Swing doors

With the door open 90 degrees, the clear opening is measured between the face of the door and jamb or jamb stop.

Pair of swing doors

With the doors open 90 degrees, the clear opening is measured between the faces of the two open doors.

Sliding or folding doors

In the fully opened position, the clear opening is measured from the edge of the leading stile to the jamb or jamb stop if present.

Pair of sliding or folding doors

In the fully opened position, the clear opening is measured between the edges of the leading stiles of the two doors.

[2]

[2]Image courtesy BHMA

What is the intended traffic flow?

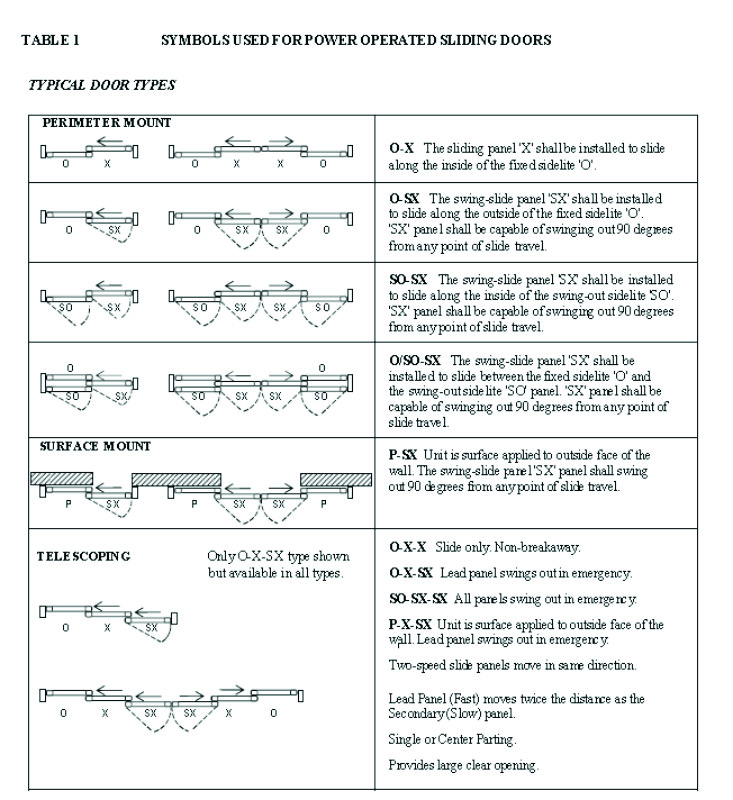

A second key factor to consider is intended traffic flow. Automatic swinging doors are typically used for directional or one-way traffic—in most cases, one door is used for ingress and the other for egress. Automatic sliding doors, on the other hand, can be the most efficient way to handle simultaneous, two-way traffic. These flat panels slide horizontally and linearly; given the variety of configurations, symbols have been assigned to the individual panels that make up an entryway. These types of sliding doors are depicted in ANSI/BHMA A156.10, Standard for Power Operated Pedestrian Doors (Figure 1).

Briefly, there are three different kinds of automatic sliding door configurations to consider during the construction process:

- single slide;

- bi-part slide; and

- telescopic slide (a good choice when wall space is limited).

No matter the configuration, the system design must include the appropriate sensors or control mats, along with signage. ANSI/BHMA A156.10 has sections addressing user safety and convenience; examples include “Control Mats or Sensors” (Section 7 or 8), “Knowing Act” (Section 9), “Entrapment” (Section 10), and “Signage” (Section 11).

Is this product up to code?

Power-operated doors are unique given the several safety concerns surrounding their installation—they open at faster speeds and with greater forces than typical manual doors. Therefore, while the type and quantity of users are two of the most important factors to consider when selecting an automatic door, it is imperative whichever style is chosen meets federal, state, and local building codes.

Codes for power-operated pedestrian doors may require the door swing out in emergencies when pushed in the direction of egress. Codes may also mandate all automatic door openings be a precise width based on the size of the store or facility. Further, in order to meet minimum compliance guidelines set forth by the Americans with Disabilities Act (ADA), there must be an adequate area around the door for maneuvering, and the door should be able to be opened with minimal effort, among other regulations.

[3]

[3]Photos courtesy Horton Automatic

Automatic doors must also follow standards set by BHMA, which are designed in large part to safeguard the pedestrians who use the store or facility. ANSI/BHMA A156.10, Standard for Power-operated Doors, requires elements such as sensors to ensure no pedestrian is hit or injured while walking through the door. Sensors also help make certain while the door opens automatically, it will not close automatically at the wrong time.

Other ANSI/BHMA standards for power-operated doors include:

- A156.19, Power-assist and Low-energy Power-operated Doors;

- A156.27, Power- and Manual-operated Revolving Pedestrian Doors; and

- A156.38, Low-energy Power-operated Sliding and Folding Doors.

At the rate at which new technologies are being developed and adapted, the standards for power-operated doors are constantly being updated. In fact, BHMA mandates these standards be reviewed for updates at least once every five years.

How important is energy efficiency?

The cost of operating automatic doors is relatively low. Further, many businesses find installing automatic doors actually decreases their energy costs. This is because it eliminates the need to worry about doors accidentally being left open. While the energy costs associated with automatic doors differ significantly depending on the climate, traffic, setting, and type being used, there are a variety of automatic doors that can be installed to help save energy.

Low-energy swinging doors, for example, save energy by operating slower than full-powered automatic doors, using very little force. They also require the user to push a button to operate. (Able-bodied individuals may also use the entrance as a manual door.) Low-energy swinging doors are the most common type of automatic doors, especially since they are designed to facilitate entrance and exit out of a building for disabled persons. Low-energy automatic sliding doors, as well as folding doors, are also available. A vestibule area, while not necessary, may also help reduce additional energy costs that sometimes result from the loss of heating or cooling.

[4]

[4]Revolving doors, however, tend to be the best option for energy efficiency. Since the door is always closed, it helps control atmospheric pressure and environmental conditions inside a building, keeping drafts out. By controlling outside air, revolving doors can also help keep things more comfortable for those working inside the facility’s entrance (e.g. security personnel). Revolving doors are also commonly used in buildings where high security is necessary. Frequently found

in places such as federal office buildings or airport gate areas, these specialized assemblies help control traffic entering and exiting a facility.

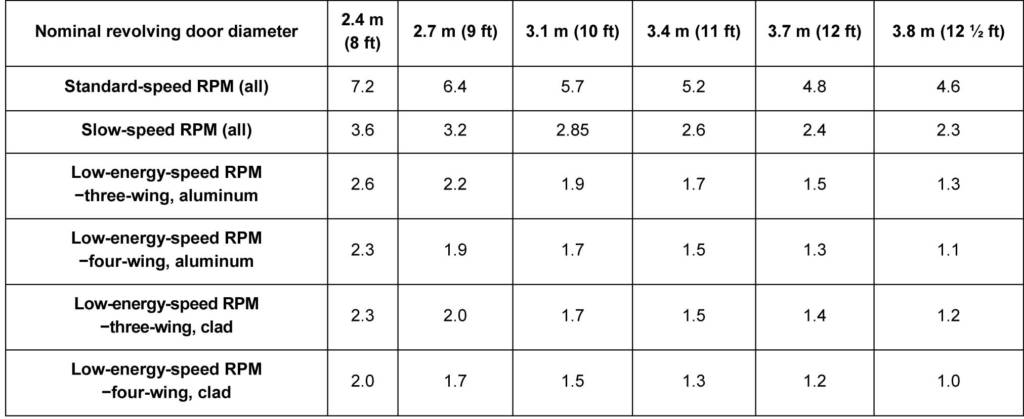

Automatic revolving doors are manufactured as complete packages. Offered in four-, three-, and two-wing designs, there are many variations, but the diameter and number of wings depend on the amount of foot traffic in and out of the facility.

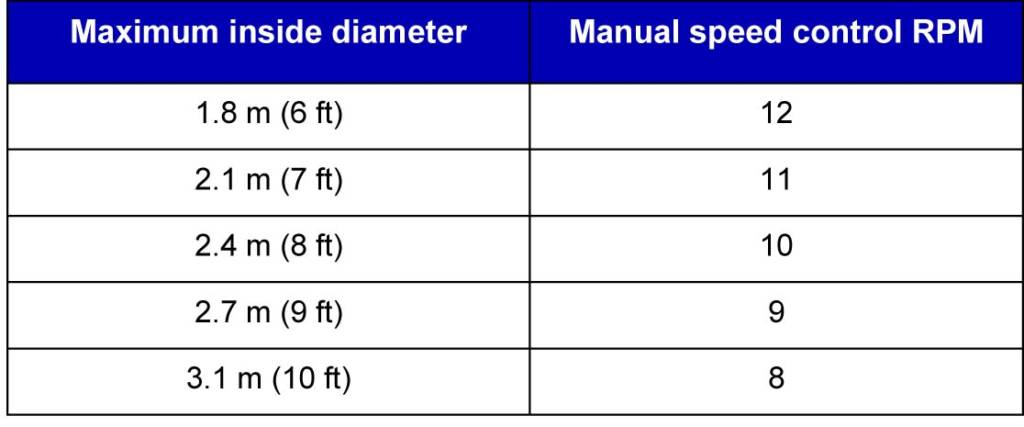

ANSI/BHMA A156.27, Standard for Power- and Manual-operated Revolving Pedestrian Doors, includes maximum allowable revolutions per minute for:

- manual revolving doors (Section 4);

- automatic revolving doors with a center shaft (Section 5); and

- automatic revolving doors with a core (Section 6).

These tables are reproduced in Figures 2 and 3 to demonstrate how energy savings can be obtained by revolving the doors are slower speeds. These tables offer an example of how pedestrian traffic flow, convenience, and energy savings are interrelated. (Energy savings could be obtained by operating the revolving door at slower speeds, but there would be trade-offs both in terms of pedestrian traffic flow and convenience.)

[5]

[5] [6]

[6]PCR applications

With energy efficiency and sustainability becoming increasingly important factors when selecting building materials, BHMA and its members took the lead in initiating the development of a product category rule (PCR) for power-operated pedestrian doors and revolving doors, which was published by ASTM International in October 2016.

A PCR is a set of specific rules, requirements, and guidelines determining what data should be gathered and how it will be evaluated when conducting the life-cycle assessment (LCA) of a product. They are essential elements for organizations and other parties interested in preparing Environmental Product Declarations (EPDs), which make it easier for architects, contractors, and other building professionals to compare the environmental impact of products when selecting materials for Leadership in Energy and Environmental Design (LEED v4) and other sustainability programs.

The Power-operated Pedestrian Doors and Revolving Doors PCR covers manual and power-operated revolving doors, along with sliding, swinging, and folding doors for use by pedestrians. It also includes their associated componentry, such as motors, sensors, and controls, where relevant. This PCR is the second one to be initiated by BHMA for the North American building industry. The first PCR, Builders Hardware UL 9004, was published in conjunction with UL Environment in 2014.

Conclusion

For every power-operated door on the market, there is its manual counterpart. Manual swinging and sliding doors, for example, are commonly used in hospitals—particularly intensive care unit (ICU) treatment rooms—due to their efficiency and cost-effectiveness. Manual revolving doors, on the other hand, are frequently specified for high-rise buildings since they remain closed at all times, thereby limiting drafts and stack effect.

Whether manual or power-operated, these doors come in a variety of finishes to add the perfect final touch to any entrance. With such a wide range of options, form need not be sacrificed or function.

Michael Tierney has served as the product standards coordinator for the Builders Hardware Manufacturers Association (BHMA) for 18 years, where he works in the development and revision of performance standards for building hardware products. Tierney came to BHMA following a 20-year career in manufacturing management at United Technologies, Honeywell, Black and Decker, and Yale Security. He is a principal member on technical committees for the National Fire Protection Association (NFPA), the A117 Committee for Accessible Buildings, ASTM, and the American National Standards Institute (ANSI). He can be reached at mtierney@kellencompany.com[7].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/jhh-sign_0204-1-e1500038325618.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/Table-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/heinzeroth_horton-4.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/fig2.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/fig3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/07/H58A7186.jpg

- mtierney@kellencompany.com: mailto:mtierney@kellencompany.com

Source URL: https://www.constructionspecifier.com/the-automatic-choice-how-and-when-to-select-power-operated-doors/