by Mike Murzyn

Building information modeling (BIM) is quickly becoming a formal procedure for modern steel construction. From software that optimizes the building envelope with information on dead load and structural load inputs for wind, seismic, and other requirements, to programs enabling sustainable design by addressing energy efficiency and green product specification, BIM processes are being adopted across the country.

Recent research conducted by McGraw-Hill Construction shows BIM adoption in the construction industry expanded to more than 70 percent of architects and engineers in 2012, compared to 17 percent in 2007 and 49 percent in 2009.1 However, while use is increasing, the concept of component-specific BIM for applications such as wall, floor, and ceiling systems is only beginning to gain traction among design and building professionals. Sometimes referred to as ‘add-ins,’ these tools allow specific products and systems to be directly imported into a larger BIM design and shared with the entire construction team, enhancing project coordination and collaboration.

Component-specific BIM for wall design

Accounting for nearly 60 percent of all metal studs in the United States, interior, non-structural wall partitions are one of the most common applications for steel framing—specifically light-gauge studs.2

Steel framing used for interior wall partitions comes in various shapes, thicknesses, and sizes. Each of these components has a specific function in the wall assembly. Selecting the correct size and thickness depends primarily on spacing of framing members and the wall’s height. Other considerations throughout the selection process include the application of the wall finishes, whether they will be applied to one or both sides, full height for composite design, and any applicable impact resistance requirements.

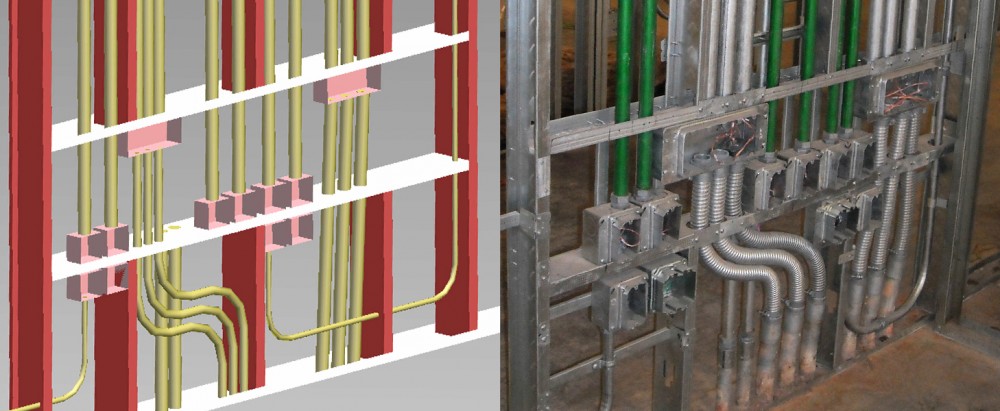

Through use of building information models, each element of a wall assembly can be created as an ‘intelligent’ object containing a broad array of product information in addition to its physical dimensions. Every element in the BIM project knows how it relates to other objects and to the overall design. This helps manage complex plans from multiple trades, as well as identify and avoid potential clashes or inconsistencies before reaching the jobsite. This is of particular importance as the wall framing phase of a project can significantly impact several other trades.

Additionally, the level of detail available through BIM add-ins is of value to architects and engineers looking to develop data-rich 3D images of interior spaces or component load-bearing wall framing. It helps in the creation of infinite views, perspectives, schedule data, and facility and operational management for the life of the building. In addition to detail on code requirements and strength, a BIM project that has taken wall types to the next step by using framing add-in software can identify the location of wall penetrations, as well as provide accurate wall shapes and opening dimensions on individual panel drawings.

Wall design and construction

There are hundreds of different wall types being used in steel framing, however, there has been little information about incorporating interior framing into BIM projects until recently.

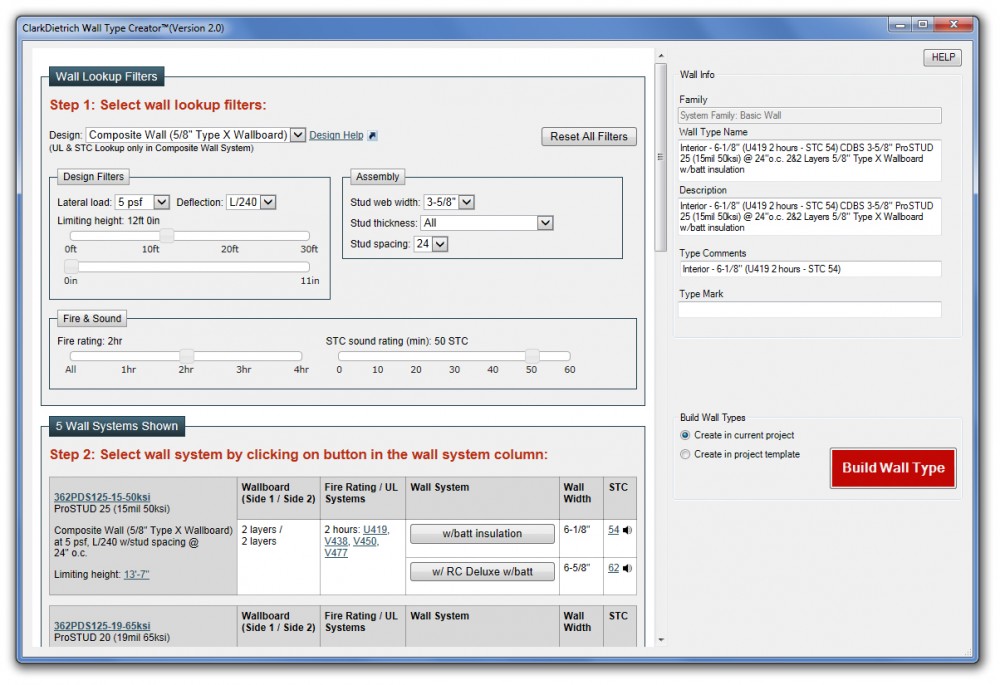

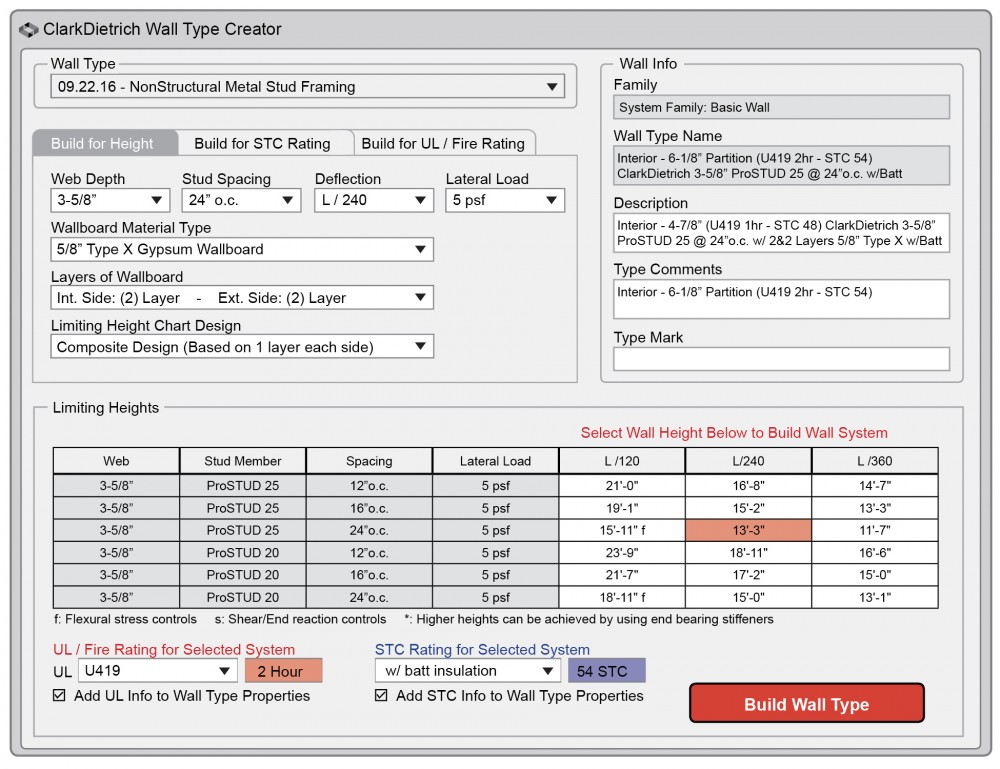

In response, some cold-formed steel (CFS) framing manufacturers offer BIM add-ins allowing users to seamlessly integrate a significant amount of wall data into new or existing models, improving comprehensiveness. The programs can also eliminate the need for temporary wall libraries requiring users to change each individual wall element to accommodate updates.

When considering different wall framing BIM add-ins, it is important to ensure the program includes all the information the design team needs, such as:

- detailed wall assembly data with product information;

- type and number of wall sheathing layers;

- overall wall width with the ability to add resilient channel and/or wall insulation;

- recycled content details for projects pursuing points under the Leadership in Energy and Environmental Design (LEED) program;

- product submittal sheet links;

- fire test data, including Underwriters Laboratories (UL) test number;

- sound test data (e.g. sound transmission class [STC] performance rating); and

- limiting height tables based on stud spacing, deflection, and interior lateral load.

In many cases, when a wall type is created, it displays the actual materials and assembly needed for correct installation. This amount of programming and detail allows the design team to see exactly how the wall needs to be constructed, what the limitations may be, and how it fits into the overall building’s construction. However, it is important to remember not all manufacturers’ BIM software add-ons are the same, and users need to be aware some systems may be more robust than others.

During the construction process, a common change order is for the removal or relocation of partition wall framings. Partition framing removal and relocation occurs due to design changes by the owner or architect, or to accommodate unanticipated intrusions, such as mechanical, electrical, or plumbing penetrations. Unfortunately, every time these changes take place, it increases the cost and time spent on the project.

However, through BIM and component-specific add-ins, building professionals can virtually identify these clashes and design the necessary changes prior to the contractor putting labor on the job. Add-ins now offer tools to simultaneously detect multiple clashes with mechanical/electrical/plumbing (MEP) and structural members into wall types, then automatically create openings in the wall around these clashes. This extra level of detail opens the lines of communication between members of the design team and increases the likelihood of open, productive conversations where changes can take place in real time. Wall framing BIM add-ins can include a wide range of information relevant to installation, code requirements, LEED guidelines, and future maintenance.

Accurate estimates and best practices

The integration of a BIM wall framing add-ins greatly benefits structural engineers and architects looking to increase their participation with the design team and produce interior drawings more efficiently and accurately. The ability to look at a BIM object or wall type and quickly understand a wall’s construction, fire and sound requirements, and limiting heights and design helps the engineering team more effectively answer questions about performance characteristics and structural integrity as well as other associated building elements.

Bid accuracy is essential. By accurately building interior walls using BIM, the framing contractor can confidently describe construction costs and immediately anticipate areas that may require additional work to prevent clashes. This information helps the contractor stay in line with the project’s budget, and better understand the time and materials needed for a particular phase. Possessing this level of information while bidding on a project can help other stakeholders easily process the data and showcase how the interior walls integrate with other plumbing, electrical, and HVAC components.

BIM also has benefits after the structure is complete. Providing as much detail as possible to facility management and building owners can help reduce costs for the lifetime of the building and make maintenance and updates more cost effective over time. A small example would be the ability for the facility management to be able to see wall framing backing locations for cabinetry or hand rails. What makes BIM unique is its ability to integrate information from various stages of the building lifecycle and easily communicate this data to the appropriate members of the construction team.

To increase efficiencies and reduce confusion, it is important BIM models and drawings provided to the construction team are as complete and detailed as possible, which encourages active and collaborative coordination between all involved parties.

As BIM continues to gain traction for projects of all sizes, there are three best practices for any individual or project team to consider:

- discuss how to organize the BIM model;

- decide on the level of detail to include; and

- share the design intent with other professionals who play a role in construction and may interact with the model.

By incorporating a wall framing add-in into the larger BIM projects, design teams are ensuring there is an elevated level of detail and awareness regarding the installation of the interiors, resulting in fewer changes and less confusion.

information on wall elements and design properties, such as Underwriters Laboratories (UL) assemblies based on fi rerating requirements, sound transmission class (STC) ratings, and limiting height design.

Conclusion

The sustainable qualities of cold-formed steel framing make it a natural fit for high-performance buildings. With various environmental and economic benefits, incorporating steel framing into a project can result in labor and cost savings for the construction team. Additionally, when using BIM add-ins, such as those for designing wall assemblies, specific system components can be seamlessly integrated into an easy-to-share information-rich model.

BIM opens the door for architects to pass models with various wall elements and design properties onto contractors with the assurance all materials will work together within the overall building design. This type of interactive platform, in which details have been linked together, gives architects and contractors a truly collaborative framework to successfully design even the most challenging wall assemblies.

Notes

1 For more, see McGraw-Hill Construction’s The Business Value of BIM in North America SmartMarket Report. Visit at www.construction.com/about-us/press/bim-adoption-expands-from-17-percent-in-2007-to-over-70-percent-in-2012.asp. (back to top)

2 See M.Reisdorf’s “Light Gauge Metal Stud Framing” at buildipedia.com/aec-pros/construction-materials-and-methods/light-gauge-metal-stud-framing-planning-and-practices. (back to top)

Mike Murzyn is a technical product and marketing manager for cold-formed metal framing manufacturer, ClarkDietrich Building Systems. He was a key developer in the company’s building information modeling (BIM) add-in wall-type creator. Murzyn has more than 15 years of experience with design, engineering, product, and software development. He can be contacted via e-mail at mike.murzyn@clarkdietrich.com.

I’m always amazed at developments in technology like this. I love what you said about BIM allowing for more accurate estimates. That’s definitely something that comes in handy when it comes to building. My dad’s looking to build a new steel structure for his work, but I’m not sure if he knows about BIM. I’ll definitely show him your article and all the benefits that you mentioned. Thanks so much for the post, Mike!

Haven’t heard about BIM before, but you are spot on with the benefits of interior steel framing. It’s time we realize the importance of utilizing supplies that could be easily recycled and has less impact on global warming and similar issues.

Hey,I will be building a new home soon and Building Information Modeling seems to be a big deal i gaining some useful knowledge.I was just concerned about the steel material i will be using because i need to be really careful while choosing it. So can you please provide me with some help regarding it.Any help will be highly appreciated.