by Todd C. Skopic, CSI, CDT, LEED AP

Today, more architectural firms are pushing the limits of building design. In turn, designing a safe and efficient building envelope is becoming more complex. The growing practice of combining open-joint rainscreens with unconventional wall orientations, such as backward sloping, offers a prime example.

In such structures, design teams want to prevent water ingress, but they also want to follow the latest building codes. Staying compliant with certain codes, such as the energy code, complicates matters by introducing certain materials and increases potential safety risks. The 2012 International Energy Conservation Code (IECC), for example, is driving the use of continuous insulation (ci), which in some cases is combustible. The 2012 International Building Code (IBC) requires buildings in Climate Zones 4 to 7 have a continuous air barrier, which in most cases also takes the form of the water-resistive barrier (WRB). Along with ci, all air and water barriers are combustible and therefore part of the compliance path for National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-loadbearing Wall Assemblies Containing Combustible Components.

In other words, today’s design teams are trying to design building envelopes that are watertight, airtight, thermally efficient, and NFPA 285-compliant. Solving this ‘cavity wall conundrum’ is possible, but it requires some familiarity with the competing design challenges and different industry standards. Most cavity wall assemblies have either a metal stud with exterior sheathing or concrete masonry unit (CMU) backup. All cavity walls share an air space to effectively drain the cavity.

Keeping the water out

According to John Straube, PhD, principal for RDH Building Science Inc., managing water with building enclosures involves the Three Ds: deflection, drainage, and drying. For water to penetrate the surface of a building enclosure, it must first be present on the wall surface. That surface must have an opening through which water can pass, and there must be a force to drive the water inward through the opening. Open-joint rainscreen systems offer an increasingly popular means to achieve the Three Ds.

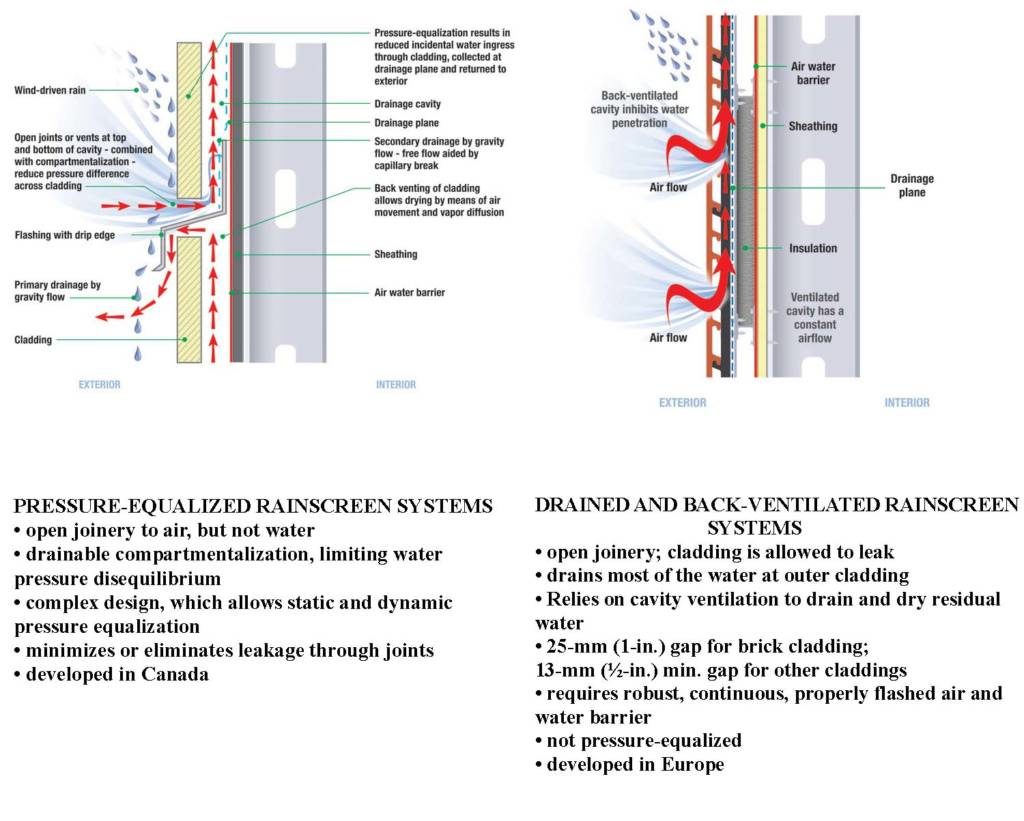

While the term ‘rainscreen’ is becoming something of a generic phrase, it is important to know there are two main types of rainscreen systems: pressure-equalized, and drained and back-ventilated. Both types must control the forces that will carry rain to the inside of the structure, including gravity, surface tension, capillary action, kinetic energy, and pressure differences. Key system highlights and differences are summarized in Figure 1.

Images courtesy Henry