by Sean Ragiel and Robert Phillips

Since the Industrial Revolution, humans have had the ability to mass consume and produce, which has led to massive waste outputs. The environment can no longer support the traditional practices of a linear economic model.

Presently, natural resources are being extracted at unsustainable rates. The United Nations (UN) reports that the extraction of primary materials has more than tripled in the last 40 years. Coupled with a spike in population growth (global population is expected to soar beyond 9 billion by 2050), humankind is burning through resources at an alarming rate. (For more, click here.)

The circular economy has not been a focal point of architects and designers in the past as factors such as schedule and budget requirements were paramount. Now, with accelerating natural resource depletion, it is becoming increasingly relevant, starting with the specification process. Design professionals’ decisions could create a ripple effect toward sustainability throughout the construction industry.

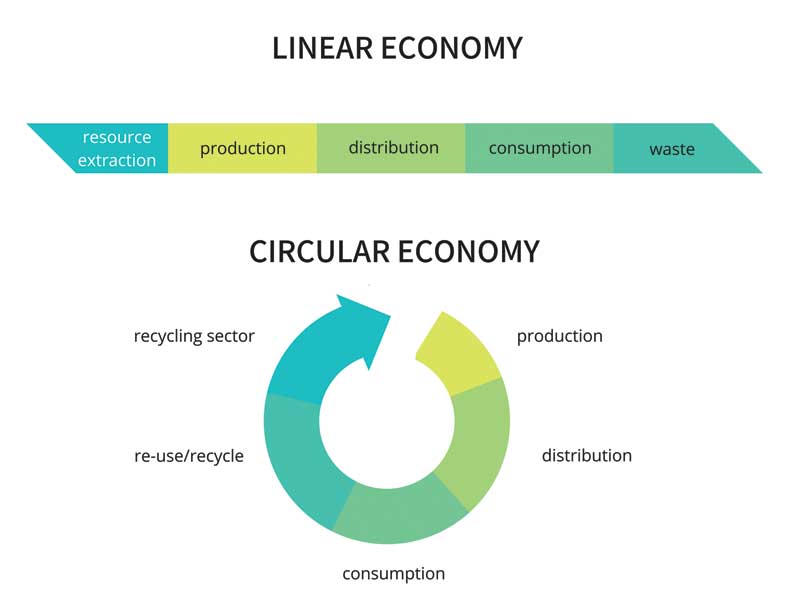

Embracing and correctly implementing a circular economic model—a philosophical change in how one conducts business—can solve current problems with immediate and long-term benefits. Instead of the traditional “take, make, and waste” system, the circular economy is a closed-loop regenerative approach of “take, make, and reuse.” This can help all supply chain entities—from sourcing, manufacturing, and operations to end-consumers—become more prosperous.

Diverting waste: Beginning with the end

The first step to changing the economy from linear to circular is reusing or recycling materials. Construction waste is one of the top offenders contributing toward landfill volume. According to the United States Environmental Protection Agency (EPA), 484 million t (534 million tons) of construction and demolition debris was generated in the United States in 2014—more than twice the amount generated by municipal solid waste. (For more, click here.) A circular economy utilizes closed-loop systems to divert these materials from landfills—recovering or restoring products, components, and materials by reusing, repairing, remanufacturing, or recycling them. When practiced properly, closed-loop recycling can increase the lifespan of a product, which would optimally become infinitely regenerative.

Image courtesy CarpetCycle

Obstacles

Time and care are needed to ensure materials are properly disposed, yet businesses tend to save time by utilizing the easiest methods, such as bulk disposal and unrefined delegation to recycling services, to accomplish their goals, which can lead to poor planning for waste diversion.

Conventional demolition processes often contribute to contaminated loads of recycled materials. The bulk method calls for all waste to be discarded at the same time. When construction materials are disposed in this manner, they are often contaminated with food and liquid waste, thereby ruining the materials’ chances of being recycled. Specifically, gypsum wallboard (GWB) and ceiling tiles are often crushed during the process, negating the materials’ recyclability and contaminating other materials such as carpet.

Bulk disposal also creates additional expenditures for recycling companies, which, in turn, leads to desaturation of local markets (i.e. the demand for regional recycling increases but the supply of services decreases) and increased future costs for reclamation.

Additionally, the latest version (v4) of Leadership in Energy and Environmental Design (LEED) and the Manhattan Solid Waste Advisory Board no longer include alternative daily cover (ADC)—the practice of using difficult-to-recycle materials as a top soil-like layer for landfills—under waste diversion. (For more, click here.) This impacts total recycling rates for construction projects and increases the cost of waste diversion.

Solutions

California is aggressively mandating the extended producer responsibility (EPR) for many consumer products. These EPR programs dictate end-of-life management costs be incorporated into the initial sale of a product. By doing so, California hopes to impart positive change in design and manufacturing practices to reduce waste and build awareness about the circular economy. However, not all states are equally aggressive, and organizations who initiate regenerative practices before governmental mandates will likely have competitive advantages in future costs. Architects and designers who participate in sustainable practices, before required to do so by law, will earn themselves credibility, gain favorable public perception, and secure customer loyalty.

When companies have consistent recycling practices, they build stronger relations with recyclers. This helps ensure companies employ proper reclamation practices and negates a recycler’s “unknowns,” which can dictate higher cost estimations. Stronger relations between businesses can also result in lower prices. During bidding phases for projects, companies with ongoing relations with recyclers might be able to win bids with an eco-friendly sales pitch.

Lastly, recycling facilities also improve local economies. The EPA’s 2016 Recycling Economic Information report shows the recycling of construction and demolition (C&D) materials created 230,000 jobs in 2007.