The deleterious situation of the pool structure

by brittney_cutler | September 1, 2021 8:32 am

[1]

[1]by Patrick St. Louis and Lauren Millman, PhD, PE

The residential high-rise swimming pool was once a luxury amenity and is now as essential as indoor plumbing. It is common to locate a pool structure on top of an occupied space, such as on a rooftop, or over a garage. While a rooftop pool is a great amenity, it can come with great fiscal and physical liabilities.

Rooftops were usually reserved for unsightly mechanical equipment or overflow parking. Yet, an insightful design professional could take advantage of remarkable vistas and envision an accessible amenity within an otherwise unoccupied space. This would crown the top of the building, or parking structure, with a luxurious pool. However, pool chemicals and chlorides will create a harsh environment for the pool structure.

Unintentional seepage of highly chlorinated water into the pool structure and property below can accelerate corrosion of the embedded steel reinforcement. Typically, this results in pit (or localized) corrosion. When pit corrosion of embedded reinforcement occurs, the repairs are costly in terms of time and money and indefinitely restrict the use of the pool. Further, the movement of water through the concrete structures could lead to efflorescence and staining of building finishes and vehicles parked below. Therefore, project teams must ponder what strategizes, or best practices, in design, construction, and maintenance can be utilized to ensure success and minimize the risks.

[2]

[2]Design and construction teams

The integration of an amenity pool should not affect the roof’s primary function, which is to ensure the structural integrity and watertightness of the space below. Watertightness, or waterproofing, is not limited to the installation of flashing or liquid-applied products. It is a systematic approach involving multiple players. Collaboration during the early schematic phase amongst design professionals and contractors can address the unique challenges brought on by rooftop pools and ensure the execution of a successful product. Since it is rare for a single individual to have complete knowledge of all aspects of design and construction, utilizing the assembly of buildings professionals (engineers, architects, contractors, subcontractors, and specialists) will result in a structurally sound, watertight, aesthetically pleasing, and fully functional rooftop pool. The collaboration of the plumbing contractor and designer can ensure the correct layout for the drainage system that would minimize water ponding and moisture intrusion into the structure below. Water intrusion can originate from a variety of systemic breakdowns, such as improper waterproofing detailing, leaks from water pipe connections, and other unsealed separations in penetrating components. Collaboration between the pool’s shell contractor and designer will ensure the pool’s structure is designed and constructed for watertightness. Additionally, for the pool’s aesthetics, the designer/client should select smooth, equitably impervious finishes. Higher resistance against water infiltration and chloride penetration will increase the life cycle of the pool structure.

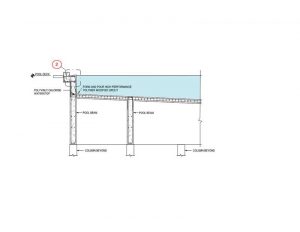

Pool assembly

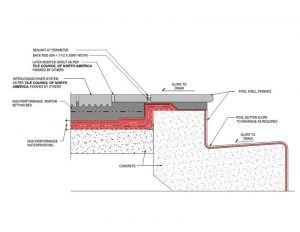

A rooftop amenity pool is usually configured as a raised deck surrounding the top of the pool’s shell. The raised deck has a paver or tile system. Underneath the paver/tile system, which can be elevated or surface-mounted, lies the roofing system on the structural deck slab. The pool’s shell is supported from below by a reinforced concrete structure. Typically, this is where the pool’s structure is incorporated into the building’s structural system.

[3]

[3]Roof/pool deck

The construction of a low-slope roof deck comes with an abundance of drainage complexities. The incorporation of the pool within the roof deck design requires an extra level of coordinated effort between the design and construction teams. Communication amongst the owner, pool contractor, and other plumbing trades is imperative when sequencing the construction associated with roof drainage and layout of associated systems. Similar to a standard roof, a pool deck is required to shed water and avoid ponding. Water ponding is visually undesirable, and it impedes foot traffic in communal areas. Most industry standards and roof material specifications consider water ponding for more than 48 hours as unacceptable. However, bathers may consider water ponding for more than 48 minutes as unattractive.

The deck should slope away from the pool. If the deck surface around the pool consists of a poor or minimum slope, then dirt and debris left by ponding water may wash into the pool. Evaporation of ponding water tends to leave behind dirt, debris, and vegetation that can stain deck finishes. Also, contamination can shorten the life cycle of the pool filtration system. The unsightly appearance of surface mold, silt, and dirt produces a slippery safety hazard at the pool edge. The slip coefficient, or resistance, is referenced by industry standards, such as those set by the Tile Council of North America (TCNA) and taken within consideration when selecting walking surface coatings or finishes. Slip resistance relates to the frictional force necessary between foot traffic and walking surfaces to avoid slippage, injury, or death of the pedestrian. Conditions created by slippery contaminants on the surfaces alter the slip coefficient and negates the proper selection of coatings or finishes.

[4]

[4]Coping caps

The edge of a pool tends to have coping incorporated within the design. The coping caps the structural horizontal element between the pool deck and shell. Its purpose is both aesthetic and functional. The coping caps prevent water from getting behind the pool shell and to shed water back into the pool drains. An alternative to the use of coping would be the placement of deck material with a slight overhang above the pool’s water surface. This method serves a similar function, as contaminated water is sloped away from the pool and bathers.

Deck drains

Beyond the pool perimeter, the rooftop deck should be an aesthetically pleasing and functional system of valleys with multiple slopes directed toward specific drains. The types include, but are not limited to, spot, strip, or French drains. The drains are strategically placed by design professionals, and like all penetrations within the pool structure, the drainage pipe is encapsulated within a waterproofing and flashing system to maintain watertightness.

Waterproofing

The waterproofing system is one of the most hidden, integral components of the pool system. It rarely gets the attention warranted. The waterproofing system insures the watertightness of the pool’s structure and spaces below. Waterproofing should be straightforward. However, client ambitions tend toward a complex design and require the need for early collaboration. A continuous multilayer waterproofing system is fully adhered to the pool’s structure, and is designed to be completely integrated into the coping and drainage system. The drainage system is sized and constructed with materials that minimize the impediment of water flow and limit blockages. A waterproofing system with properly terminated penetrations reduces the risk of moisture intrusion. Specifications and protocols that address the complete encapsulation of the entire surface area of the pool structure, including the multilayer waterproofing system, can ensure the necessary construction sequencing is carried out with warranties preserved.

[5]

[5]Crack suppression

Due to high chloride content, water that reaches the steel reinforcement in the concrete can be detrimental to the integrity of the structure. A waterproofing system with a high chemical chloride resistance and hairline crack bridging capabilities should be coordinated with the design-construction team to ensure essential details, penetrations/tie-ins, and separations are considered and worked out among trades.

The design and installation of water-stops within the concrete pool shell structure is an important addition of a well thought out waterproofing system. Water-stops serve as an obstruction of the incidental passage of water through concrete joints. They should be placed systematically between the vertical and horizontal structural concrete elements. The water-stops should be able to withstand a chemically aggressive environment.

Additionally, concrete admixtures can be used to improve durability performance and provide waterproofing characteristics to the concrete structure. Admixtures that are resistant to aggressive chemical environments can also contribute to the watertightness with the ability to self-heal by crystallizing and sealing static hairline cracks. Admixtures provide supplemental waterproofing and chemical protection to concrete water holding structures. This is a means of waterproofing the concrete by way of growing a non-soluble crystalline structure within the pores and capillary paths of the concrete. During the early stages of design, the concrete mix design should be coordinated with the admixture manufacturer’s representative to insure proper dosage and strength. To avoid under-dosage, it is recommended to specify the admixture manufacturer’s minimum percentage by weight of cementitious material requirements to meet its high-performance standards. The modified concrete will be treated as typical concrete, meaning there are no differences when applying decorative finishes or additional waterproofing tie-ins. However, the installer of the surface-applied material (to be applied over treated concrete) is responsible for coordinating and taking the necessary measures to ensure compatibility and bond to the treated concrete.

While industry standards recognize reinforced concrete structures will have cracks to some extent, the pool’s concrete structure requires an approach that is more stringent and limits cracking. Adding to the complexity of the engineering design, a rooftop pool is typically above the parking garage or occupied space. This limits the ability to have a uniform placement of vertical structural supports. The spacing and frequency of these supports is ideally engineered to avoid deflections that would contribute to the cracking of the pool’s concrete shell structure and/or the pool finishes above. Spans exceeding safety guidelines put the pool’s structure at risk and could lead to costly repairs and extensive service interruptions.

While engineering codes and guidelines have provisions for complexity of design, non-uniform spans, and/or other challenges, these only address the structure’s immediate integrity and not its longevity. Additional measures implemented during the design and schematic phases could help reduce deflections. For example, early coordination between the plumbing and structural engineer could reduce the amount of penetrations (and those abandoned) and help with reducing overall congestion. The routing of plumbing, service lines, and pool equipment during design, with specific consideration for easing the installation of waterproofing system and maintenance, would lend to a pool shell structure that could further resist deflections and unanticipated stresses.

[6]

[6]Electrical and lighting

Early collaboration between the electrical contractor/engineer and the pool designer will ensure the proper pool equipment is specified, such as pool pumps, heaters, and whirlpool jets. The specifications should not only address pool health regulations and general code requirements, but also include considerations about energy efficiency and maintenance. Energy-efficient equipment may help offset the owner’s costs and help minimize maintenance scheduling in the long term.

Bonding

While proper specifications and electrical connections for the pool system are important, electrical safety should not be overlooked or minimalized. The pool contractor and electrician should be well versed in electrical bonding and grounding methodology. Unlike physical safety elements, such as non-skid walking surfaces or pool fences, electrical safety like bonding and grounding occasionally take a back seat. All metallic components associated with the pool structure should maintain equal resistance. For instance, pool ladders must be electrically interconnected (bonded) and grounded to the earth. Additionally, structural and pool engineers should ensure structural steel reinforcement is bonded. Typically, a detail is incorporated where electrical and metallic components of the pool are joined with a wire to form a non-resistive path between them. This is to prevent an electrical potential from existing. The goal of bonding is to connect, contain, and prevent the transmission of electrical voltage that would endanger a life or damage pool equipment. Bonding should not be an afterthought.

Grounding

Analogously, the goal of grounding is to ensure the bonded pool components redirect harmful excess electrical current to the ground and away from pool equipment and life. The pool’s electrical network and electrical panel must be grounded to dissipate excess electricity. Without a proper grounding system set in place, people or pool equipment could become the conductor. Without both bonding and grounding, the risk to life safety is too high and the repairs will be a costly and timely endeavor.

Lighting

Ambient lighting specifications and layouts tend toward the vision of the designer. However, certain building codes and local municipalities have governances to protect local wildlife. If the client wants lighting available for night swimming, then certain requirements by governing bodies need to be met, which includes those imposed by the health department. Early and frequent coordination will help promote safety and performance, while maintaining aesthetics.

Exposed concrete—garage

It may not exist in all configurations, but the underbelly of an elevated rooftop pool structure may occupy a garage structure below. Cars exhaust various toxic (i.e. carbon monoxide) and non-toxic gases (i.e. carbon dioxide [CO2]). Governing bodies within the mechanical building code and/or industry standards such as those set by the American Society of Heating, Refrigerating and Air-conditioning Engineers (ASHRAE) have mandated venting requirements for the design of a garage that addresses the carbon monoxide emitted from vehicles. However, the CO2 exhausted by vehicles idling or traveling within the garage can have an effect on the concrete structure. Carbon dioxide can react with freshly placed concrete to produce a soft chalk residue on the surface through a chemical reaction known as carbonization (production of calcium carbonate). Carbonation of reinforced concrete is a form of deterioration and contributes to the corrosion of reinforcement. Other contributors to the corrosion of embedded steel are oxygen from the atmosphere and the moisture from humidity or leaks from the pool above. Depending on the conditions, exposed and unprotected concrete may require an anti-carbonation coating to protect against the ingress of CO2 and other deleterious elements, while still allowing the concrete to breathe.

Conclusion

Early coordination between design professionals and the construction team is necessary to put preventative measures in place that will extend the pool’s life, maintain the structural integrity of the pool, avoid imminent danger to personnel, prevent damage to the pool and property below, and unnecessary future repairs.

The pool system is complex, but attention to details, specifications, and the interaction between trades can yield a safe, functional, and beautiful rooftop amenity pool. Waterproofing is symbolic of those collaborative relationships. Allocating sufficient preparation to the waterproofing application is not unlike the prep required at the start of the pool design. An inadequate approach can lead to failures in the structural integrity or damage to the pool and property below.

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/bigstock-June-In-Palm-Springs-374038246.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/corrode-embed-reinforcement-under-pool-structure-3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Diagram-1-revised.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Diagram-2-revised.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/no-waterproofing-tie-ins_-water-intrusion-below.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/pool-drained-for-timely-repairs.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Patrick-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2021/09/Lauren.jpg

Source URL: https://www.constructionspecifier.com/the-deleterious-situation-of-the-pool-structure/

[7]Patrick St. Louis, LEED GA, is a project director with Thornton Tomasetti (TT) in the Fort Lauderdale, Florida, office. St. Louis has been with TT for over eight years with a primary focus on forensic architecture. He has a bachelor’s degree from Florida Atlantic University. St. Louis is reachable via email at pstlouis@thorntontomasetti.com.

[7]Patrick St. Louis, LEED GA, is a project director with Thornton Tomasetti (TT) in the Fort Lauderdale, Florida, office. St. Louis has been with TT for over eight years with a primary focus on forensic architecture. He has a bachelor’s degree from Florida Atlantic University. St. Louis is reachable via email at pstlouis@thorntontomasetti.com. [8]Lauren Millman, PhD, PE, is a senior project director with Thornton Tomasetti (TT) in Fort Lauderdale, Florida. Millman has been with

[8]Lauren Millman, PhD, PE, is a senior project director with Thornton Tomasetti (TT) in Fort Lauderdale, Florida. Millman has been with