Photo © BigStockPhoto.com

Protecting against leap frog

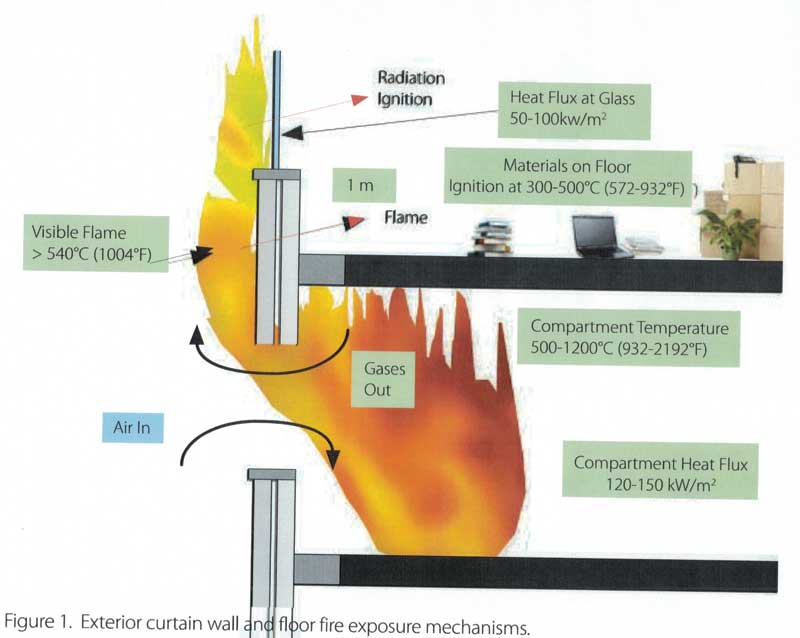

Initially, model building codes included only cursory mention of fire protection of exterior curtain walls and floor-to-wall perimeter voids, or spandrel construction. Consequently, architects, designers, contractors, and code officials often adopted untested and uncertain solutions. Later, more effective products were developed and tested for curtain wall fire protection in accordance with ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, and NFPA 285. However, because neither of these test standards specifically evaluate vertical fire spread via leap frog, codes only partially addressed the fire risk by requiring minimum vertical separation of openings, or full sprinkler protection of the building. Employing prescriptive minimum vertical spacing requirements between openings limits design flexibility. While sprinkler systems are very effective at controlling interior fires, studies have reported, globally, the percentage of exterior wall fires occurring in buildings with sprinkler systems ranges from 15 to 39 percent for the building height groups considered. This may be due to external fire sources or failure of sprinklers. (To read more, consult the Fire Protection Research Foundation’s [FPRF’s] June 2014 report, “Fire Hazards of Exterior Wall Assemblies Containing Combustible Components,” by Nathan White and Michael Delichatsios.)

Currently, there is a huge void in the fire-testing community—both with respect to code requirements and test standards—when it comes to identifying and protecting against the leap-frog exterior fire spread phenomenon. The International Building Code (IBC) Chapter 7, “Fire and Smoke Protection Features,” requires the fire-resistance rating of building elements, components, or assemblies be determined in accordance with test procedures set forth in ASTM E119 or Underwriters Laboratories (UL) 263, Standard for Fire Tests of Building Construction and Materials. Chapter 7, Section 715.4, “Exterior curtain wall/floor intersection,” of IBC further details the description and procedures for fire and smoke protection at the perimeter void between the exterior curtain wall and floor intersection. This specific section focuses only on the required protection for the perimeter void between the floor slab and the interior face of a curtain wall. ASTM E2307 is the test method specifically developed to evaluate the ability of perimeter fire barrier joint systems to prevent the interior spread of fire through the perimeter void into the room above.

Proposed test method

The leap-frog effect is a unique fire condition. When ASTM first published E2307 in 2004, it was acknowledged an additional test method was needed to mitigate the effects of fire exposure on the spandrel and vision glass area from the exterior of the building.

ASTM Committee E05 on Fire Standards has been working on the development of a new test method, currently titled, “Proposed New Standard Test Method for Determining the Fire-test Response Characteristics of Building Spandrel Containment Systems Due to External Spread of Fire.” This new test method is intended to simulate the fire exposure from a post flashover compartment fire venting through an opening, onto the exterior spandrel area, or portion of the exterior cladding immediately above a window opening. When published, the test can be used to evaluate the effectiveness of exterior spandrel areas above the opening, and any glazing. This ASTM method is currently being balloted, and is anticipated to be approved for publication in 2019.

This draft test is designed to evaluate the fire performance of the portion of an exterior wall assembly directly above an opening, principally the building perimeter spandrel system, with or without glazing, to impede the spread of fire to the interior of the room or the story immediately above it, via fire spread on the exterior of a building. A task group of ASTM E5.11 is charged with further developing a test method for evaluating the performance of this construction detail not addressed by any other fire test method. For example, features forming vertical channels on a building façade (e.g. vertical shades or a recess in the façade) increase the hazard of high fire exposure to the façade. Features disrupting vertical air movement along the façade (e.g. balconies) protect the façade above these features from high fire exposure.

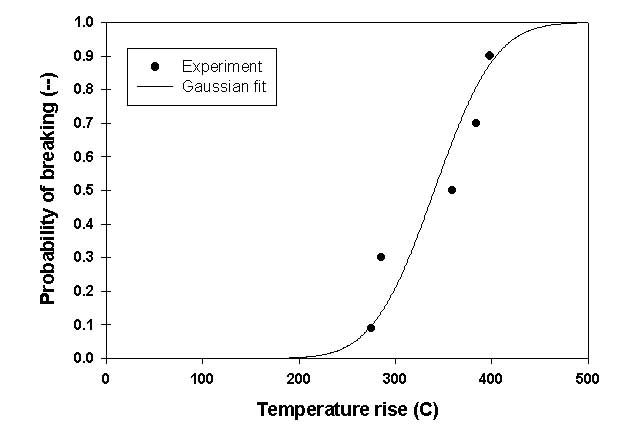

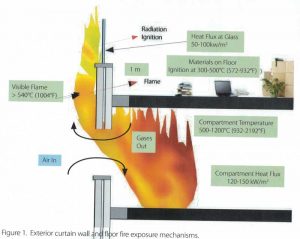

Literature reviews and independent research have been used to help develop the criteria for the current ASTM draft standard. Studies have confirmed in 6-mm (236-mils) float glass, first cracking occurs when the bulk glass temperature reaches around 110 C (230 F). This corresponds to a heat flux of around 3 kW/m2. In the same study, glass fell out when exposed surface temperature reached 415 to 486 C (779 to 907 F) or heat flux of around 35kW/m2 (Figure 2).

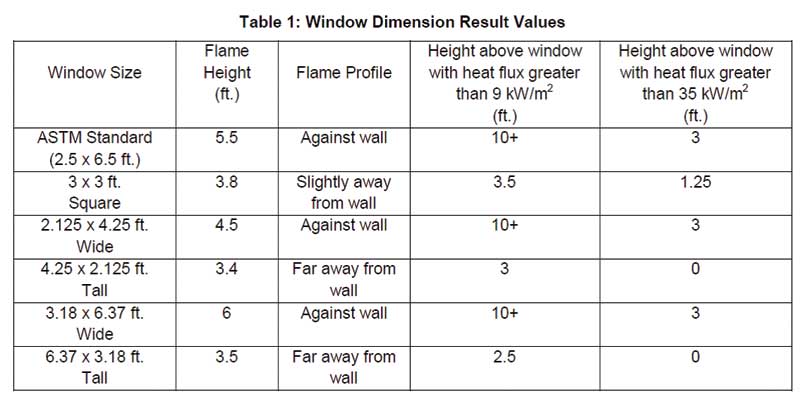

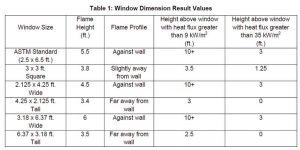

To verify the proposed apparatus provides adequate flame exposure to evaluate leap frog, additional research was also conducted by students at Worcester Polytechnic Institute (WPI), Massachusetts. This report included a literature review and computer modeling conducted using the exposure conditions and configuration of ASTM E2307. The project reviewed varying window dimensions, conducted heat flux calculations at various heights on the exterior wall above a window opening, and at the flame propagation on the exterior wall (Figure 3).