The Leap-frog Effect: Protecting tall buildings from exterior fire spread

by Samantha Ashenhurst | May 31, 2018 8:30 am

[1]

[1]by Tony Crimi, P.Eng., MASc.

Fires can spread through buildings even without the involvement of the cladding system materials. There are numerous examples of fire spread from the room of origin to the space above via vertically adjacent windows, but prior to the Grenfell Tower fire in the United Kingdom, most have caused only property damage. A majority of deaths or injuries on floors other than the fire-origin floor were a result of smoke. However, some methods of insulating buildings to improve their sustainability and energy efficiency are changing the external surfaces of structures. this has resulted in an increase in the volume of potentially combustible materials.

Additionally, different construction techniques favoring energy performance are being utilized. As recent high-rise fires around the world have demonstrated, it is critical designers remain vigilant against potential fire hazards, particularly as the industry transitions to tighter and more energy-efficient buildings, and adapts traditional perceptions to these new methods of construction.

The intersection of the exterior wall and the floor assembly provides a number of different paths for vertical fire spread in buildings. Each of these paths is addressed by different test standards. The building codes establish different requirements for each of these potential paths to prevent the spread of fire. The intent is to confine a fire to the room of origin and prevent propagation to adjacent areas.

Fire spread

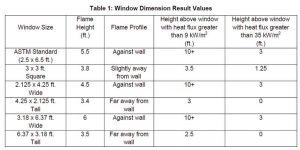

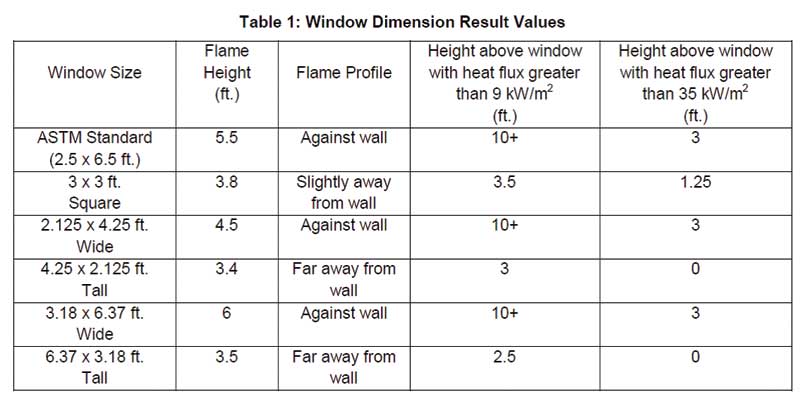

Real fire experience has taught the author ineffective curtain wall design, perimeter void fire protection, or inadequate spandrel protection can allow fire to spread through the space between floors and walls, the window head transom, and the cavity of the curtain wall. This can occur either by ignition of the exterior building cladding materials, through window glass breakage, or around melted aluminum spandrel panels. Conceptually, fire can easily spread to adjacent floor levels at the exterior wall via three paths (Figure 1).

[2]

[2]Image courtesy Tony Crimi

Through voids

Fire can spread within the building through the void space created between the edge of the floor and an exterior curtain wall. These are protected by perimeter fire barrier systems. Standards to assist in the proper design and installation of fire barrier systems include ASTM E2307, Standard Test Method for Determining Fire Resistance of Perimeter Fire Barriers Using Intermediate-scale, Multistory Test Apparatus, for system design specification, and ASTM E2393, Standard Practice for On-site Inspection of Installed Fire Resistive Joint Systems and Perimeter Fire Barriers, for proper installation.

Through cavity

Fire can also spread through a void or cavity within the exterior curtain wall. In this situation, fire would spread by a path within the concealed space of the exterior wall, or along the outer surface of the exterior wall. According to some jurisdictions, these protected assemblies are tested to be compliant with the National Fire Protection Association (NFPA) 285, Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Non-loadbearing Wall Assemblies Containing Combustible Components, which evaluate flame propagation due to combustible materials used in exterior wall assemblies.

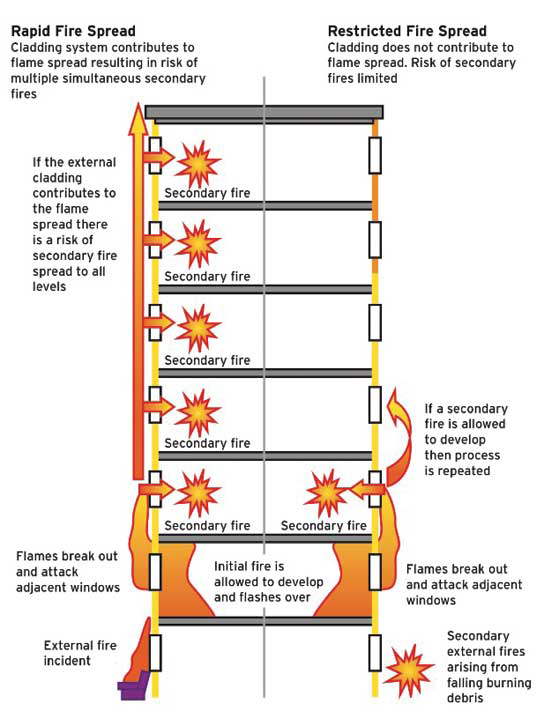

Leap frog

This is a window-to-window mechanism where combustible materials behind an upper window are ignited as a result of the intense heat from flames projected out of a lower window. This mechanism is currently addressed in the U.S. building codes prescriptively, using spandrel panels or sprinkler protection. A new ASTM test method is under development. This condition represents a significant fire exposure, created when the magnitude of flame and hot gasses escaping through a window opening is sufficient to cause the re-entry of the fire or ignite combustible materials, in the room above the story of fire origin. This can occur when fire spreads vertically up the exterior of the building, circumventing the interior perimeter fire barrier joint system, any inherent fire resistance of the exterior wall assembly, or a sprinkler system. When this mechanism of fire spread occurs at a given floor, it has the potential to repeat through the same mechanism to every floor above it. Therefore, this phenomenon is referred to as the “leap-frog” effect.

Flame extension and heat fluxes to the window areas above an opening can be expected to be greater where combustible claddings are employed in lieu of traditional code-prescribed fire-resistive spandrel panels. The design characteristics of a spandrel panel and the perimeter fire barrier joint system are important to enhance the ability of the exterior wall to protect against vertical fire spread. Fire tests such as ASTM E2307 have shown typical aluminum-framed curtain walls require glass installed in the spandrel area immediately above openings be appropriately protected. Additionally, this testing has demonstrated the aluminum mullions also require insulation protection to support the perimeter fire barrier joint system. Otherwise, the frame can melt, soften, or distort, and cannot support the perimeter joint protection or spandrel wall system. These measures help keep the glass spandrel panel, and any associated fire barrier joint system, intact.

[3]

[3]Photo © BigStockPhoto.com

Evolution of curtain wall façade construction

Curtain wall design has become common in commercial construction in the last 40 years. Metal cladding is often used because it is attractive and can be easy to clean. For example, it was installed on the Grenfell Tower, a 24-story, mid-1970s structure in the United Kingdom, to give it a more modern look. Curtain wall systems (i.e. non-structural external cladding spanning multiple floors) are typically supported by clip or girt mounting methods, connecting the framing system at the edge of each floor. This normally results in a gap between the edge of each floor and the curtain wall. It has become more common for building codes to permit non-traditional materials to be employed in larger and higher buildings in order to improve energy performance, reduce water and air infiltration, and allow for aesthetic design flexibility.

These non-traditional systems include:

- exterior insulation finish systems (EIFS);

- metal composite claddings;

- high-pressure laminates; and

- weather-resistive barriers (WRB).

The combustibility of the exterior wall assembly components, in the author’s experience, has been known to directly impact the fire hazard to the building.

Combustible materials employed in exterior walls have played a contributing role in numerous fires worldwide. The aptly named “Torch Tower” high-rise building in Dubai, United Arab Emirates, has seen two major cladding fires in the past four years. The tower first went up in flames in February 2015. More than 1000 people were evacuated from the 337-m (1105-ft) tall, 87-story building. The structure was repaired, but experienced a second cladding fire on August 4, 2017. According to officials at the Dubai Civil Defense Department, electric circuits caused the 2015 fire, and a cigarette carelessly tossed from a balcony and landing on a plant in a lower balcony resulted in a fire in 2017. While there were no reported deaths, Dubai Civil Defense reported 38 apartments were damaged in the fire, and 64 floors were affected by the blaze.

Experts also cite combustible cladding as a factor in similar fires in which flames raced along the sides of buildings, including:

- a high-rise fire in a building under renovation in Shanghai, China, in 2010 that resulted in the death of at least 58 people when it re-entered the building on multiple floors;

- a 2015 apartment fire in Azerbaijan that left 16 people dead; and

- a 2009 fire at TV Cultural Center in Beijing, China, that killed a firefighter.

Similarly in Melbourne, Australia, more than 400 people were evacuated from the Lacrosse Tower on November 25, 2014, when a discarded cigarette on a balcony started a fire that quickly spread up the face of the building. While there were no fatalities, owners of the Lacrosse Tower, at the time of writing, are claiming more than $12 million in damages, and lawyers for the owners are claiming almost $1 million in lost rent, money spent on emergency accommodation during the fire emergency, and compensation for an increase in insurance premiums since the blaze.

During the One Meridian Plaza (Philadelphia) fire in 1991, flames broke through several windows around a major portion of the fire-origin floor, exposing the floor above to auto-exposure from flames lapping up the side of the building. Additional alarms were called to bring personnel and equipment to the scene for a large-scale fire suppression operation. As the fire developed on the 22nd floor, smoke, heat, and toxic gases began moving through the building. Vertical fire extension resulted from unprotected openings in floor and shaft assemblies, severe deflection of the floor assemblies, and the lapping of flames through windows on the outside of the building. (To read more, click here.)

Most recently, the tragic fire in the Grenfell Tower on June 14, 2017, killed at least 80 people, but police said only 21 of those victims could be formally identified. The fire spread rapidly up the exterior of the building, circumventing the interior fire protection features, re-entering from the exterior, and eventually consuming every floor.

What all of these fires have in common is the ability of the fire to spread by one or more of the three mechanisms described earlier, either singly or in combination.

[4]

[4]Photo © BigStockPhoto.com

Protecting against leap frog

Initially, model building codes included only cursory mention of fire protection of exterior curtain walls and floor-to-wall perimeter voids, or spandrel construction. Consequently, architects, designers, contractors, and code officials often adopted untested and uncertain solutions. Later, more effective products were developed and tested for curtain wall fire protection in accordance with ASTM E119, Standard Test Methods for Fire Tests of Building Construction and Materials, and NFPA 285. However, because neither of these test standards specifically evaluate vertical fire spread via leap frog, codes only partially addressed the fire risk by requiring minimum vertical separation of openings, or full sprinkler protection of the building. Employing prescriptive minimum vertical spacing requirements between openings limits design flexibility. While sprinkler systems are very effective at controlling interior fires, studies have reported, globally, the percentage of exterior wall fires occurring in buildings with sprinkler systems ranges from 15 to 39 percent for the building height groups considered. This may be due to external fire sources or failure of sprinklers. (To read more, consult the Fire Protection Research Foundation’s [FPRF’s] June 2014 report, “Fire Hazards of Exterior Wall Assemblies Containing Combustible Components,” by Nathan White and Michael Delichatsios.)

Currently, there is a huge void in the fire-testing community—both with respect to code requirements and test standards—when it comes to identifying and protecting against the leap-frog exterior fire spread phenomenon. The International Building Code (IBC) Chapter 7, “Fire and Smoke Protection Features,” requires the fire-resistance rating of building elements, components, or assemblies be determined in accordance with test procedures set forth in ASTM E119 or Underwriters Laboratories (UL) 263, Standard for Fire Tests of Building Construction and Materials. Chapter 7, Section 715.4, “Exterior curtain wall/floor intersection,” of IBC further details the description and procedures for fire and smoke protection at the perimeter void between the exterior curtain wall and floor intersection. This specific section focuses only on the required protection for the perimeter void between the floor slab and the interior face of a curtain wall. ASTM E2307 is the test method specifically developed to evaluate the ability of perimeter fire barrier joint systems to prevent the interior spread of fire through the perimeter void into the room above.

Proposed test method

The leap-frog effect is a unique fire condition. When ASTM first published E2307 in 2004, it was acknowledged an additional test method was needed to mitigate the effects of fire exposure on the spandrel and vision glass area from the exterior of the building.

ASTM Committee E05 on Fire Standards has been working on the development of a new test method, currently titled, “Proposed New Standard Test Method for Determining the Fire-test Response Characteristics of Building Spandrel Containment Systems Due to External Spread of Fire.” This new test method is intended to simulate the fire exposure from a post flashover compartment fire venting through an opening, onto the exterior spandrel area, or portion of the exterior cladding immediately above a window opening. When published, the test can be used to evaluate the effectiveness of exterior spandrel areas above the opening, and any glazing. This ASTM method is currently being balloted, and is anticipated to be approved for publication in 2019.

This draft test is designed to evaluate the fire performance of the portion of an exterior wall assembly directly above an opening, principally the building perimeter spandrel system, with or without glazing, to impede the spread of fire to the interior of the room or the story immediately above it, via fire spread on the exterior of a building. A task group of ASTM E5.11 is charged with further developing a test method for evaluating the performance of this construction detail not addressed by any other fire test method. For example, features forming vertical channels on a building façade (e.g. vertical shades or a recess in the façade) increase the hazard of high fire exposure to the façade. Features disrupting vertical air movement along the façade (e.g. balconies) protect the façade above these features from high fire exposure.

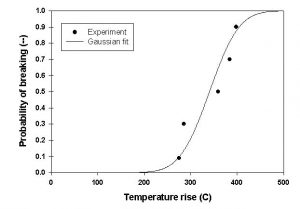

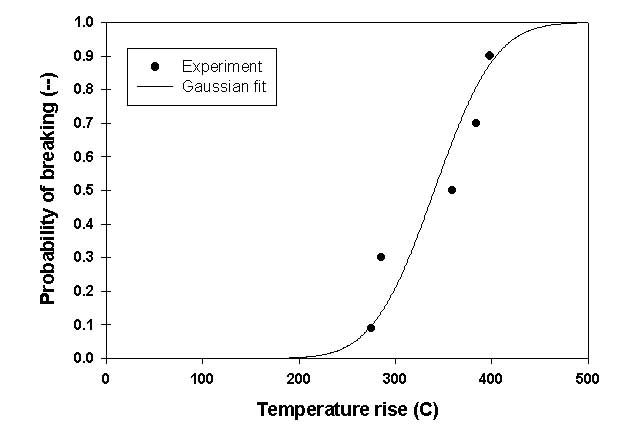

Literature reviews and independent research have been used to help develop the criteria for the current ASTM draft standard. Studies have confirmed in 6-mm (236-mils) float glass, first cracking occurs when the bulk glass temperature reaches around 110 C (230 F). This corresponds to a heat flux of around 3 kW/m2. In the same study, glass fell out when exposed surface temperature reached 415 to 486 C (779 to 907 F) or heat flux of around 35kW/m2 (Figure 2).

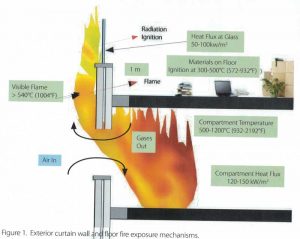

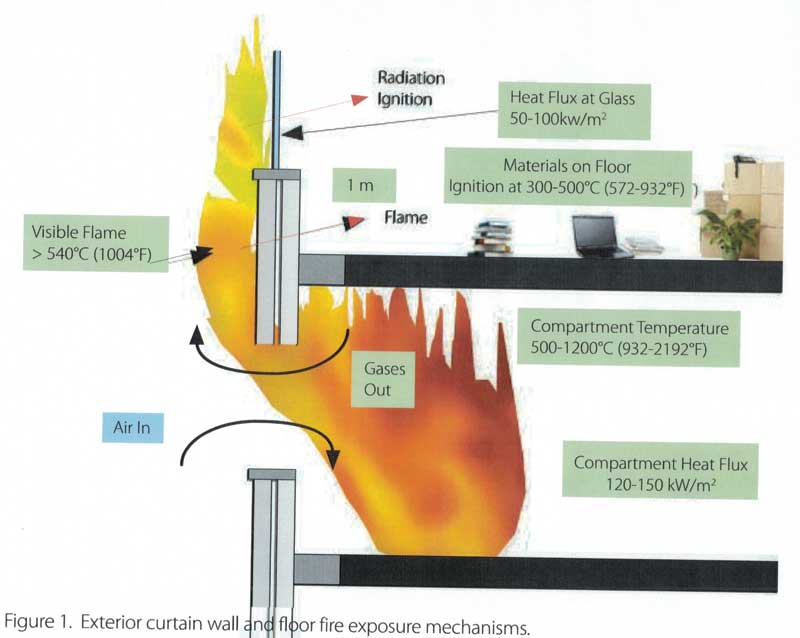

To verify the proposed apparatus provides adequate flame exposure to evaluate leap frog, additional research was also conducted by students at Worcester Polytechnic Institute (WPI), Massachusetts. This report[5] included a literature review and computer modeling conducted using the exposure conditions and configuration of ASTM E2307. The project reviewed varying window dimensions, conducted heat flux calculations at various heights on the exterior wall above a window opening, and at the flame propagation on the exterior wall (Figure 3).

[8]

[8]Photo courtesy Tony Crimi

The proposed leap-frog test uses the same apparatus as ASTM E2307 and NFPA 285, with the same fixed window opening size, to create the fire exposure on the exterior side of the spandrel panel or curtain wall. The “opening” is 762 mm (30 in.) high and 1981 mm (78 in.) wide. The research report concludes the current size of the fire (time-temperature curve/burner) is sufficient to provide:

- incident heat flux of 35 kW/m2 at a height of 0.91 m (3 ft) above the head of the window opening; and

- incident heat flux of 9 kW/m2 at a height of 3 m (10 ft) above the head of the window opening.

In addition to the WPI research findings, testing of a typical aluminum curtain wall system with a 914-mm (36-in.) spandrel height was conducted at Southwest Research Institute, San Antonio, Texas, and witnessed by UL. Instrumentation was installed to provide a temperature profile and incident heat flux measurements vertically and horizontally during the test. The flame temperatures and heat fluxes were determined to be consistent horizontally across a 610-mm (24-in.) width, when measured at 305, 610, 914, and 1220 mm (12, 24, 36, and 48 in.) above the opening.

Based on the research findings, the ASTM task group agreed to utilize the approach of measuring the incident heat flux behind the exterior wall on the floor above the burn room. The choice of pass/fail criteria was selected based on the level of heat flux required for unpiloted ignition of easy-to-ignite combustible materials, and glass breakage. Those heat flux limits are consistent with the normal temperature rise limits imposed by ASTM E119 when determining fire resistance ratings of assemblies (i.e. a maximum average temperature rise of 121 C [250 F], together with a maximum individual temperature rise of 163 C [325 F]). These represent an incident heat flux of 1.8 to 2.6 kW/m2 at the measurement location (Figure 4).

When considering floor-to-floor fire spread via openings (e.g. windows), the nature of exterior wall/curtain wall designs is a critical factor dictating the relative capability to resist floor-to-floor fire spread. Key factors impacting curtain wall resistance to vertical fire spread, which need to be evaluated by testing, can include:

- full or partial height vision glass or spandrel panel design;

- nature of the glass used to construct glazing system;

- the curtain wall components installed (e.g. framing, spandrel panels, rainscreen, and air gap);

- vertical or horizontal projections on exterior that may deflect or enhance flame behavior;

- building geometry at curtain wall—inclined, staggered, or sloped;

- operable windows/openings—size and orientation; and

- the vertical alignment of windows/openings.

Among its other functions, a spandrel containment system impedes the vertical spread of fire via exterior fire spread, from the floor of origin to the floor(s) above.

Conclusion

The industry’s understanding of exterior fires and their mechanism of spread in buildings has been researched and reported. However, the potential of fire spread, particularly as related to super high-rise buildings and their façades, presents unacceptable levels of risk to building occupants. Current code practices recognize the successful record of full sprinkler protected high-rise buildings, and only require the void space between the curtain wall and the floor slab be resistive to fire spread using a perimeter fire barrier system. However, as the desire to improve energy efficiency becomes increasingly urgent, more innovative ways to insulate buildings are changing the external surfaces of buildings with an increase in the volume of potentially combustible materials being applied. A number of significant fires have demonstrated the potential risks.

Building geometry and exterior projections of the curtain wall or building structural elements can have a beneficial or negative effect on flame length extension and heat flux exposure to curtain wall elements above the fire compartment. This can be particularly important if operable windows, ventilation openings, or inclined exterior wall designs are employed. Of course, any such condition can allow the unrestricted passage of flames and hot gases from a fire on a floor below into the space above. Also the position of the opening relative to the expected flame extension is important in assessing the risk of a leap-frog event.

The current code requirements focus on the fire testing of specific assemblies not necessarily consistent with the design goals of the architect; yet the larger concern is the associated risk of the fire’s leap-frog effect for high-rise buildings. A review of the history of significant high-rise fire losses where the leap-frog effect was evident shows that the hazard is real and can be catastrophic. Key factors impacting a curtain wall’s fire resistance are being addressed by the proposed ASTM standard. This regulation will be useful when there is a need to provide enhanced protection or evaluate a curtain wall assembly’s potential performance when subject to uncontrolled heat/flame exposure. Most importantly, the fire risk for high-rise, buildings requires the consideration of several factors including:

- the engineering design of the sprinkler systems;

- fire department response capabilities;

- the occupancies and associated fire loads;

- the building’s evacuation approach;

- compartmentation features; and

- security threat assessment scenarios.

With appropriate consideration and evaluation of these risk factors, it is possible to select a curtain wall design meeting both the aesthetic goals and fire-safety objectives for any building.

Based on several years of literature review involving high-rise fires, research reports, fire modeling, and actual fire test data developed for the ASTM task group, the author believes there is sufficient justification and information available to proceed with the development and implementation of the ASTM E5.11.20 “leap-frog” standard.

Tony Crimi, P.Eng., MASc., is a registered professional engineer and founder of A.C. Consulting Solutions Inc., specializing in building- and fire-related codes, standards, and product development activities in the United States, Canada, and Europe. Working with manufacturers and industry associations, he advocates for the approval and safe use of materials and products, and for their code recognition. Crimi has more than three decades of experience in the area of codes, standards, testing, and conformity assessment. He is an active participant in International Code Council (ICC), National Fire Protection Association (NFPA), ASTM, Underwriters Laboratories (UL), and International Organization for Standardization (ISO), and is the immediate past-chair of the National Building Code of Canada (NBC) Standing Committee on Fire Protection. Crimi can be reached at tcrimi@sympatico.ca[9].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/bigstock-Office-building-top-view-backg-227601292.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/crop_fig1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/bigstock-194295559.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/bigstock-194295895.jpg

- This report: http://web.wpi.edu/Pubs/E-project/Available/E-project-042910-100106/unrestricted/ASTM_Leap_Frog_Effect-RPR-ERS.pdf

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/Figure-3-fire.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/Figure-4-fire.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2018/05/Parque-Central.jpg

- tcrimi@sympatico.ca: mailto:tcrimi@sympatico.ca

Source URL: https://www.constructionspecifier.com/the-leap-frog-effect/

[6]

[6] [7]

[7]