Photo © Fabral

Integration with metal roofing

Marrying a metal building envelope with phase-change materials makes sense. Metal roofing and wall systems promote energy efficiency with inherent reflective qualities allowing buildings to stay cooler and use less electricity for mechanical systems. This means a decrease in power generation and a reduction of pollutants.

Following the fundamental property of materials to absorb heat when they melt and to release it when they solidify, PCMs absorb and release heat at pre-set temperatures. While materials exhibit this behavior, some go through this phase change at or near room temperature, absorbing and releasing heat in the process.

When both elements (metal envelope and PCMs) are brought together, and the integrated system is placed into the structure of a building, the phase-change material is able to absorb heat during the day and then release it at night. This makes the entire energy cycle more efficient. Fewer kilowatt hours are used to heat and cool buildings while the phase-change material intelligently captures and releases otherwise-wasted energy.

When integrated into a metal wall or roofing system, PCMs have been shown to provide energy savings up to 30 percent in heating and up to 50 percent in cooling, therefore reducing indoor temperature fluctuation. Integrated systems also improve occupant comfort and efficiency by:

- reducing the need for mechanical heating and cooling;

- decreasing greenhouse gas (GHG) emissions;

- lowering overall energy use; and

- shifting energy usage away from peak demand.

A roofing or wall assembly with metal panels, insulation, and PCMs creates an ideal application for reasons including installation ease and design aesthetics. Architects who do not want the energy-efficient system to alter the overall design aesthetics or standard construction practices and materials have options beyond adding more insulation or photovoltaic (PV) systems. Highly energy-efficient roofs and walls can be designed with thinner assemblies, negating the need for thicker, bulkier exterior envelopes. Additionally, these systems can be installed at much lower cost than solar power systems and offer better payback without incentives or subsidies.

An integrated metal roofing or wall system with phase-change materials is easy to install and can be integrated in both new construction and retrofit applications. In the assembly of a roofing system, PCM is placed over the decking and under the insulation. For new or retrofit applications, PCM can be stapled, screwed, or glued to metal or wood studs.

Unlike insulation or vapor barriers, PCM does not require a continuous and unbroken plane to be effective. The more space covered by the material, the better the results—performance is based on thermal mass as opposed to thermal resistance. However, since gaps will not negate the material’s effectiveness, it is less dependent on skilled installers than other building envelope enhancements.

PCM in a wall assembly, either new or retrofit, is placed between the wallboard and the insulation within the framing members.

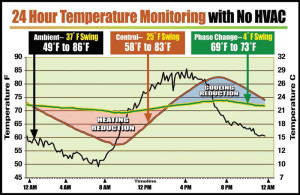

Image © Phase Change Energy Solutions Inc.

Passing the test

An increasing amount of testing has been done to measure the efficiency of phase-change materials in building envelope construction. In Arizona, two identical sheds measuring 4.8 x 3.6 x 2.4 m (16 x 12 x 8 ft) were constructed to test the effectiveness of PCM. In both sheds, the wood stud walls were insulated to an R-value of 19, while the roofs were insulated to R-30. The interiors were finished with gypsum board. The 4:12-steep roofs received composition shingles. This ratio is determined by the vertical rise divided by the horizontal span.

To round out preparation for testing, the buildings were conditioned with high-efficiency heat pumps controlled by digital programmable thermostats set at 22.7 C (73 F) for heat mode and 25 C (77 F) for cooling. In the control shed, no phase-change materials were installed. In the other, PCM was added to the walls and roof.

HVAC run-times were greater for the control building and less for the PCM-lined building. The implications of shorter run-times include:

- lower cost for energy;

- lower levels of carbon emissions;

- smaller HVAC units needed;

- less stress on the power grid during peak times;

- more consistent indoor temperature; and

- greater tenant comfort.

While architects and specifiers have the opportunity to include phase-change materials in metal walls, roofs, and buildings, there are potential applications in other areas of industry and manufacturing as well, which include:

- transporting combustibles and hot or cold perishables—such as food, pharmaceuticals, and

- organ or blood tissue—by maintaining temperature in the containers;

- electronics and telecommunication shelters to protect temperature-sensitive equipment

- greenhouses requiring AC and/or heat to protect plants;

- laboratories needing precise control of cooling and heating for chemical reactions; and

- increased solar efficiency in crystalline silicon PV applications.

As mentioned, a building can experience energy savings up to 30 percent in heating and up to 50 percent in cooling through PCMs. In warmer climates, the interior temperature becomes consistently comfortable so AC can often be eliminated. In all cases, energy savings from phase-change materials enable smaller, more efficient heating and cooling units to be installed. Direct savings are realized by reduced electric and gas utility bills.

Third-party testing has proven these statistics. The energy-efficient metal system used in the Asheboro church was inspired by testing performed by the U.S. Department of Energy’s (DOE’s) Oak Ridge National Laboratories (ORNL) and funded by the Metal Construction Association (MCA). During the third quarter of 2009, three experimental attics using different retrofit roofing technologies were constructed at the ORNL Natural Exposure Testing Facility.