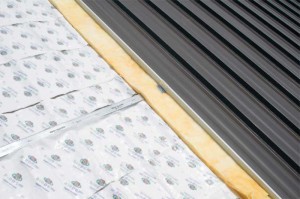

Image © Fabral

The first test attic represents the traditional way of roof retrofit, where the old roofing materials are removed for disposal in landfills and replaced with a new roof cover. The two remaining attics utilized roof-over-the-roof technologies. Both employ metal roofing panels capable of being installed directly over the existing roofs without requiring the old material’s removal. These metal panels contain a cool-roof coating to minimize solar heat gains.

In the final test attic, roof-integrated PV laminate and PCM were also used. The test data demonstrated a roof-over-the-roof can be an effective way of not only refurbishing the aged surface, but also improving energy performance of existing roofs. During the winter and spring of 2009 and 2010, the PV/PCM attic showed a

30 percent reduction in the heating load compared to the conventional shingle attic. On average, the maximum daytime temperatures were about 15 percent lower in the PV/PCM attic compared to the shingle attic. This difference was higher in the late spring and summer, with a 50 percent reduction in cooling load and a 75 percent reduction in nighttime heat loss.

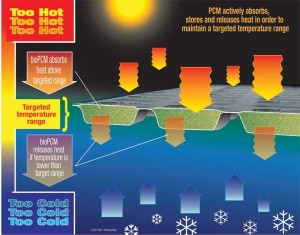

Image © Phase Change Energy Solutions Inc

The best conditions for PCM

The interior temperature of a PCM building is more stable, providing a comfortable environment. Evening out the temperature of a building lessens extreme temperature spikes. This alone improves a building’s energy efficiency. The cool-down and heat-up times are greatly altered. Phase-change materials integrated with metal roofing and wall panel systems are most effective in buildings with low thermal mass, where energy costs are high and in climates with large internal and external temperature gradients. While financial justification can be made in nearly all building types and climate zones, return on investment (ROI) is maximized when outside ambient temperatures fluctuate higher or lower than a building’s internal operating temperature.

Bio-based phase-chase materials significantly reduce the temperature variant so the mechanical equipment can work less to maintain the building’s desired internal operating temperature. In climate-controlled buildings, the results are lower energy consumption and lower operating costs. In non-climate controlled buildings, the result is greater comfort because internal temperatures are moderated when there are large daily swings in outside ambient temperature.

Sustainability factors

In addition to energy savings and comfort, a PCM system holds a range of sustainability benefits. It can be made from natural products such as highly refined soybean and palm oils. The material behind bio-based phase-change technology is completely biodegradable and recyclable. If a building is demolished, the PCM can be extracted and applied toward another project. Buildings incorporating metal roofing and/or walls assemblies integrated with phase-change material are eligible for the following credits under the Leadership in Energy and Environmental Design (LEED) program:

- Sustainable Sites (SS) Credit 7.1, Heat Island Effect–Non-roof: one point for covering 50 percent of hardscape with reflective roofing;

- SS Credit 7.2, Heat Island Effect–Roof: one point for roofing with high reflectivity and high emissivity;

- Energy and Atmosphere (EA) Credit 1, Optimize Energy Performance: up to 19 points for a 48 percent energy budget reduction under ASHRAE 90.1, Energy Standard for Buildings Except

- Low-rise Residential Buildings (reflective roofing and PCMs contribute to this reduction);

- EA Credit 2, Onsite Renewable Energy: one to seven points for onsite renewable energy (e.g. PV), one point for producing one percent of required energy, and seven points for 13 percent of required energy;

- Materials and Resources (MR) Credit 2, Construction Waste Management: one point for recycling/salvaging 50 percent of site waste, and two points for 75 percent (metal serves as the primary contributor);

- MR Credit 4, Recycled Content: one point if entire building contains 10 percent of recycled content and two points if it contains 20 percent or more (metal is primary contributor); and

- MR Credit 5, Regional Materials: one point if 10 percent of products are manufactured or harvested within 805 km (500 mi), two points if 20 percent or more of products are manufactured or harvested within 805 km of the project site.

Conclusion

When phase-change materials are used on a project, the temperature will be more comfortable for the building’s inhabitants. By integrating these products into roof and wall systems, a building can maintain a consistent and comfortable temperature, while delivering durability to the design.

David A. Brown, PE, is the product development director for Fabral—supplier of metal products for building envelopes in architectural, commercial, post-frame, industrial, transportation, and agricultural applications. He has spent the past 28 years serving technical and sales and marketing needs in the metal wall and roof construction industry. Brown is an industry member of Construction Specifications Institute (CSI) and achieved CSI’s Construction Documents Technology (CDT) certification. He can be reached via e-mail at dbrown@euramax.com.