by Jim D. Koontz, PE, RRC, and Thomas W. Hutchinson, CSI, AIA, FRCI, RRC, RRP

Hail and other forms of physical damage (including from foot traffic or workmanship) to roofs result in millions of dollars of economic loss each year. At least one state, Texas, allows insurance companies to provide a reduction in rates when a hail-resistant type of roofing material is installed. Owners of properties that are largely self-insured are beginning to realize the importance of calling for such assemblies.

Empirical experience has long suggested ethylene propylene diene monomer (EPDM) roof systems fare well in hailstorm events. To validate this, the EPDM Roofing Association (ERA) decided to embark on a testing program for the synthetic rubber material.

The technical committee decided an important question in the design, insurance, and contractor communities concerns performance of aged, in-situ EPDM roof covers. Therefore, it was determined the test sample pool would include both new membrane material and samples from the field. The major EPDM manufacturers each provided new 1.2 x 1.2-m (4 x 4-ft) 1524-µm (60-mil) material samples, had new 60-mil material heat-aged, and procured 60-mil samples from roof covers that have been exposed between five and 20 years.

Prior to sending the samples for testing, the EPDM material was fully adhered to various 1.2 x 1.2-m substrates: mechanically fastened polyisocyanurate (polyiso) insulation, mechanically fastened wood fiber board, and 12-mm (1⁄2-in.) plywood. Between 20 and 35 samples of each roof cover category were sent for testing.

Field experience from the examination of thousands of roofs and from Roofing Industry Committee on Weather Issues (RICOWI) reports have clearly shown hail damage can be the result of several factors:

- diameter of the hail stone;

- type of roofing system;

- roof cover’s age;

- substrate beneath the primary roof system;

- surface temperature at the point of impact.

To evaluate an assembly’s resistance to hail damage, these reference points have to be considered as part of a research project.

NBS impact research

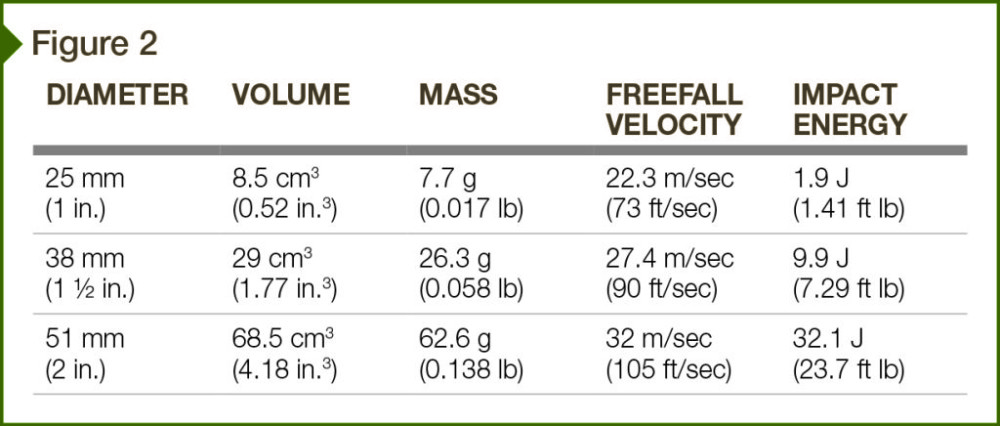

In the early 1960s, the National Bureau of Standards (NBS) in Washington, D.C., conducted research by impacting roof systems with ice spheres. The group’s Sydney H. Greenfield performed this initial research and, in 1969, generated technical article NBS 23, Hail Resistance of Roofing Products. Referring to earlier research, he initially determined hail’s freefall velocity (Figure 1).

The technical data indicates the freefall velocity of the hail increases with hail stones of larger diameters. A key factor is the amount of ‘impact energy’ imparted to a target or roof surface. Simply stated:

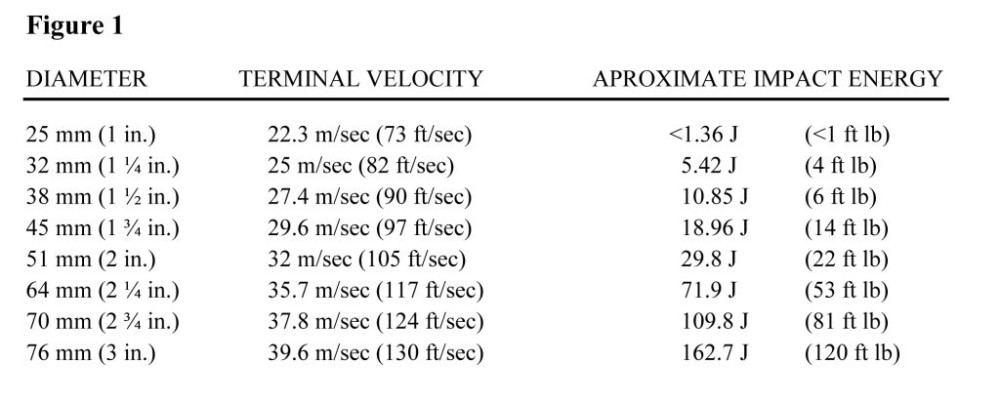

Impact energy = kinetic energy = ½ mass * velocity2

The mass of a hailstone obviously depends on the volume of the ice sphere and density of the ice. The density of hailstones is typically valued at .91.

Volume of a sphere = 1.33 * Ð * Radius3

A substantial difference in impact energy occurs with only slight changes in diameter. It is important to note the impact energy between 25, 38, and 51-mm (1, 11⁄2, and 2-in.) hailstones. This increase in size represents a 100 percent change in diameter, but a 1590 percent increase in impact energy (Figure 2).