The standard for hardware performance

by Catherine Howlett | March 1, 2013 10:35 am

[1]

[1]by Michael Tierney

Schools, hospitals, and government buildings share essential characteristics; they house sensitive information, are designed to be used for long periods, and have public responsibilities. Specifiers and building managers must ensure safety and security needs are met by selecting the appropriate door hardware.

The suite of Builders Hardware Manufacturers Association (BHMA) standards is a tool for architects, designers, specifiers, and engineers working on non-residential, public projects to help ensure buildings are accessed and used as intended.

The industry group is composed of U.S. manufacturers in categories such as:

- cabinet hardware and hinges;

- sliding and folding doors; and

- power doors and components.

BHMA is the only U.S. organization creating standards for builders hardware through the American National Standards Institute (ANSI). ANSI/BHMA standards are written criteria defining appropriate operation, test values, and safety criteria for builders hardware products. In addition to ensuring hardware quality and performance through its development of standards, BHMA sponsors third-party certification of hardware products.

[2]

[2] [3]

[3]The standards certify essential products for daily use, including locks, hinges, exit devices, and gaskets.

What are BHMA standards used for?

As quasi-public buildings, hospitals, schools, and government facilities must balance safety and security with openness and use. BHMA standards provide specific information on the way materials are tested for certification. What is relevant in the lab should prove relevant to real-world use.

All BHMA standards have certain elements in common including:

- designated criteria of performance for the product;

- product performance levels;

- expectations for use of products; and

- tests the product has passed.

The most important features are evaluated in terms of security, durability, strength, finish, and operation. The results garnered from tests allow specifiers to answer the questions of “how does it work?” or “how do I want it to work?”

The three steps of the certification process are:

- independent testing;

- statement of compliance; and

- third-party follow-up testing and auditing.

When a product has been certified and tested under these standards, it will then be listed in BHMA’s Certified Products Directory, along with applicable model and type numbers.

Most of these standards provide a numbering system that uniformly applies to all tested builders hardware. Therefore, specifiers acquainted with the standards can look at a hinge standard, see the specific numbers assigned to it, and know what level of performance it is expected to achieve. This gives a common language to the industry and, depending on the standard, can include a lot of information.

[4]

[4]How to read a BHMA Certification

Using the example of a hinge specification, type numbers will read as:

A2412

Where:

A–Section A;

2–Material (Wrought Brass or Bronze);

4–Type (Half Surface Hinge);

1–Description (Anti-friction Bearing); and

2–Performance Grade (Grade 2).

After consulting the BHMA certification number of a project, a specifier or engineer can determine whether the product performs the required task.

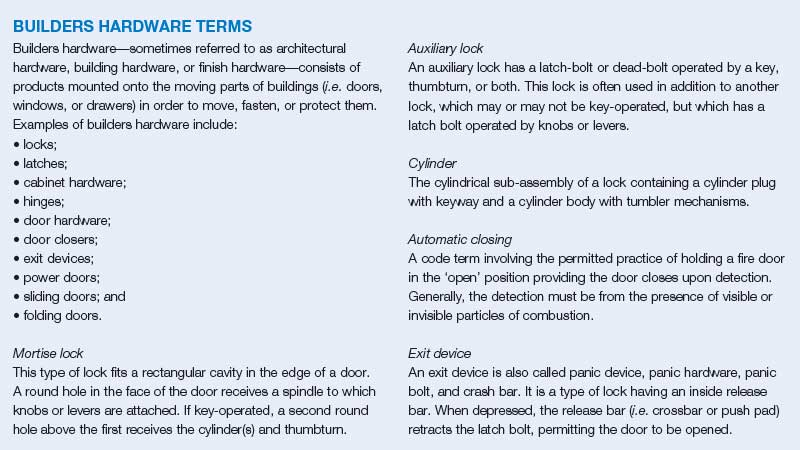

Grades are determined by tests designed to measure a product’s performance capabilities. They assist the specifier in determining which product is most appropriate for a project. Performance assurance is especially important for products that have an impact on life safety and security. For those less familiar with builders hardware, definitions for the products and technical jargon are included throughout the standards. (See “Builders Hardware Terms” at the end of this article.)

After the specification process, these standards can also be applied to help facility mangers determine if a product is operating correctly, and to ensure it was installed and made for the right purposes. For example, when an exit device is pushed, it should not require more than 67 N (15 lb) of force, as stated in the standards. Also, many of the standards for builders hardware come with illustrations for better specification.

As mentioned, builders hardware impacts life safety and security, and it is therefore one of the few categories of functional hardware that is specified. These components are subject to repeated use and wear, yet must withstand constant operation. The standards are not designated for use by facility type, but some facilities tend to rely on certain standards.

Hospitals

Hospitals have a large number of practical and operational matters to take into consideration during design planning. They must be functional for staff and personnel, while also providing easy access for patients with limited mobility. By limiting the amount of touch surfaces, which can pass germs in highly trafficked areas, the potential for spreading infection is minimized. Also, as a highly populated building, a hospital must meet safety and fire requirements when it comes to builders hardware.

Low-power-operated doors are common throughout many hospitals. BHMA 156.19, Power-assist and Low-energy Power-operated Doors, deals with assemblies that allow patients to easily navigate and access the hospital. They also have the added benefit of making it unnecessary to touch a handle. Placing sensors in front of doors that open when someone walks in front of them helps reduce potential for the spread of germs and infections through touching a handle or button.

Push/pull passage locks offer a similar benefit. They are often specified for patient rooms to provide privacy, but they can be opened without a lever so nurses or other staff members can exit or enter the room with their hands full.

Hospitals also commonly rely on BHMA 156.24, Delayed Egress Locks. For a patient suffering from dementia and requiring a certain level of security in a hospital, wandering can be prevented by using the features of a delayed egress lock. However, the hospital must balance egress during an emergency situation with the security needed to keep patients safe. A delayed egress lock does this by activating an alarm to notify personnel the door is being used, but will open within 10 seconds to allow for exiting during an emergency. Specifiers must be acutely aware of situations like this in a hospital, and the BHMA standards are essential to properly executing this process.

Hospitals often use National Fire Protection Association (NFPA) 101, Life Safety Code, which includes references to the BHMA standards, including those for exit devices and low-power-operated doors.

Schools

Schools face a particular set of challenges in their design and operation, but they are not necessarily much different than those posed by other buildings being discussed.

Similar to other public buildings, schools must meet requirements for assembly areas. Exit devices, also known as ‘panic devices,’ are common. Mostly used in auditoriums and gymnasiums, they are required for educational occupancies that can be highly crowded and difficult to escape. The devices employ a release bar across the door that, when pushed, releases the latch bolt and allows the door to easily open.

Many schools employ door closers, especially as they are required on fire doors. For example, a door in a location designated to help stop a fire from spreading (e.g. fire partition, fire barrier, or fire wall) needs a closer to ensure it is completely closed. The testing for Grade 1 door closers endure two million cycles, to make certain the best products do not fail when they are needed. The full array of requirements for their performance is described in ANSI/BHMA A156.3, Exit Devices.

BHMA standards for schools also include ANSI/BHMA A156.2, Bored and Preassembled Locks and Latches, and ANSI/BHMA A156.13, Mortise Locks and Latches, Series 1000. These bored and mortise locks provide a special classroom function; they enable a door to be secured from the outside solely with a key—this way a teacher cannot be locked out of the room.

For schools, nothing less than Grade 1 products generally suffices, meaning products tested and certified perform at the highest level under the toughest conditions. All builders hardware in schools need exceptional durability and strength for the long-term wear and tear that will be put on the products. Tests such as the vertical load test are not much different than the stresses these products actually face once in use.

[5]

[5]the product holds up under repeated use.

Government buildings

Government projects can include any number of facilities such as local police stations, town halls, and municipal buildings. A key focus on these buildings is security, both of sensitive materials and personnel. Top-grade builders hardware—such as locks that are certified by BHMA—are essential to ensuring top-level security.

BHMA A156.30, High-security Cylinders, is commonly used for government buildings with features over and above typical cylinders. Products under this standard must pass three categories of tests: key control, destructive, and surreptitious.

Key control means limiting accessibility to key blanks, such as creating no markings on the keys or leaving trails of the bittings (the geometry of a key) or serial numbers; it also applies to electronic locks that control the audit trail and time-zoning. For destructive tests, the locks undergo drilling and impact evaluations over and above the normal amount. Surreptitious tests seek to ensure a lock provides safety against picking. They ensure high levels of resistance to picking and bumping, which are common lock-breaking techniques.

BHMA-compliant hinges have anti-friction bearings so they hold up for long-lasting use. For higher security use, hinges with non-removable pins that perform at Grade 1 level are tested to withstand 2.5 million cycles.

In addition to high-security cylinder locks, all the lock and exit device standards have security concerns designed into them. Latching products have security operating hardware standards as well.

While government buildings are rightly focused on security, they also have access needs, to ensure smooth functioning in places often visited by the public. Power-operated doors produced to ANSI/BHMA A156.10, Power-operated Pedestrian Doors, and ANSI/BHMA A156.19, provide access by automatically opening. In some doorways, levers have replaced knobs.

Government buildings must often follow International Code Council (ICC) A117.1, Accessible and Usable Buildings and Facilities, for accessible routes. The operable part of a door in this case must be functional with one hand, and should not require tight grabbing or twisting of the wrist. Buildings following this code need to consult BHMA standards for lever locks, exit devices, or power-operated doors to ensure compliance.

Certified products

BHMA is primarily concerned with safety and performance, but builders hardware is also expected to be functional and attractive. It is imperative to ensure the finish holds up on any visible components, and are subjected to constant wear and tear.

BHMA ensures this under A156.18, Materials and Finishes. Products with certifications for finishes undergo testing—such as salt spray, ultraviolet (UV) resistance, hardness, humidity, and solvent resistance—to ensure a product will not scratch, corrode, or discolor. A product frequently touched generally has higher requirements than a product not in constant contact with users, such as a door closer.

A BHMA-certified product can be distinguished from other products by the “BHMA Certified” logo on the product or its packaging. A list of certified products can be found in the BHMA Certified Product Directory (www.buildershardware.com/cpd_entry.html[6]).

Conclusion

Designing a building or facility for both ease of access and security is a complex task. It can often come down to the details of whether or not a plan is successful. Relying on the BHMA standards allows specifiers and architects to ensure the builders hardware they use will help them bring plans to life.

[7]

[7]

Michael Tierney has been the standards coordinator for the Kellen Company since 1999. He coordinates the development and revision of 35 Builders Hardware Manufacturers Association (BHMA) performance standards covering a broad range of products form gaskets to hinges to power operated doors. Tierney is a principle member on technical committees for the National Fire Protection Association (NFPA), the International Code Council’s (ICC’s) A117 Committee for Accessible Buildings, ASTM, and American National Standards Institute (ANSI). He can be contact via e-mail at mtierney@kellencompany.com.

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/12/School.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/Big-Bullet-01-2.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/Big-Bullet-02.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/Hammer-0102.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/Little-Bullet-01-02.jpg

- www.buildershardware.com/cpd_entry.html: http://www.buildershardware.com/cpd_entry.html

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2013/03/Builders-Hardware-Terms.jpg

Source URL: https://www.constructionspecifier.com/the-standard-for-hardware-performance/