Theory of a self-drying flat roof

Thermodynamic solution

To develop a better understanding of how a roof works under specific environmental loads, an understanding of the second law of thermodynamics is necessary. In basic terms, the law says energy shall maintain a state of thermodynamic equilibrium—hot to cold, high pressure to low, and high to low vapor. In a cold climate, the roof will be hotter than the interior space under summer conditions. Therefore, the heat flow will be from hot to cold (exterior to interior). If a leak occurs at the roof membrane level during the summer (cooling season), the moisture will try to migrate from a high concentration area to one of low concentration, such as the roof enclosure to the occupied space below. The moisture will not be able to equalize as a vapor retarder would generally be located on the warm side of the insulation and does not allow for effective moisture transport to an area of lower concentration.

The conditions during the heating season are reversed as the heat from the interior occupied space will want to migrate up through the roof enclosure to the exterior colder temperature. Moisture will follow the same path as the heat during the winter months (hot to cold). Due to the vapor pressure and cold temperatures, if the vapor retarder is not continuous, there will be a possibility of condensation at the underside of the roof membrane.

An incomplete or defective roof membrane/vapor retarder will allow air, vapor, and moisture to enter the roof enclosure and migrate freely based on the interior and exterior conditions, thereby negatively impacting the roof’s performance and durability. The enclosure must be allowed to achieve equilibrium to increase its resiliency.

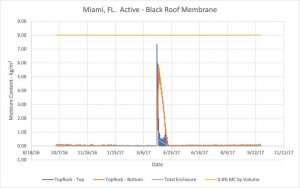

New construction materials can help roof enclosures equalize (dry) when wet—two such technologies are vapor permeable thermal insulation and variable vapor permeable smart vapor retarder (Figure 1). Drying to the interior can theoretically be achieved by replacing the standard non-vapor permeable insulation (traditionally polyisocyanurate [ISO]) with vapor permeable (mineral wool) insulation, and using a variable vapor permeable smart vapor retarder instead of a standard vapor retarder. Inward drying at the vapor retarder interface of the roof enclosure is recommended as there needs to be an ultra-low vapor permeable membrane protecting the components and space below.

The intent of using two vapor ‘open’ materials is to efficiently diffuse and dry the moisture from the area of high concentration (leak) to the area of low concentration (interior occupied space) by using the second law of thermodynamics and energy from the sun.

Theoretically, during the cooling season the moisture/vapor will diffuse through the vapor permeable insulation (via the variable vapor permeable smart membrane) and to the interior where the moisture could be removed by means of venting. The energy from the sun (membrane color) will impact the drying period as the amount of radiation absorbed will dictate the temperature gradient through the roof enclosure. During heating days, the roles will be reversed due to the temperature’s gradients (i.e. inside to outside). While this scenario makes sense in theory, can it work in practice and possibly be modeled to demonstrate the ‘in-situ’ performance?