Thermal efficiency in glazed curtain wall systems

by Katie Daniel | September 1, 2016 10:26 am

by Ben Mitchell, CSI, Chad Ricker, and Jerry Schwabauer

With glazed façades dominating urban landscapes, the strides made to improve the energy efficiency of glass are well-documented and generally well-understood. However, much more quietly, the framing members of wall and window systems have also been re-engineered. The performance improvements in these less-discussed components are poised to add up to big gains in efficiency.

Glazed openings have traditionally been major points of unwanted heat loss or gain for building interiors. Exacerbating the problem, alloyed aluminum—the most popular framing material in the industry—is also highly conductive. Nevertheless, aluminum is prized for its many advantages (such as durability, recyclability, and strength), and its conductivity can be reduced by the addition of a thermal barrier. This is important because aluminum is a primary building material in buildings pursuing sustainability, including those seeking certification under the Leadership in Energy and Environmental Design (LEED) program.

While R-value has become a very familiar measurement of thermal insulation, U-value is the key measure when it comes to glazed fenestration. R-value measures resistance to heat transfer, while U-value, or ‘thermal transmittance,’ measures the rate of heat transfer. Therefore, the two numbers are not a direct inverse, but can be thought of as opposites in that a higher R-value (i.e. high value of insulation) and a lower U-value (i.e. low amount of heat and/or cold being transferred across a barrier) is ideal. U-values are commonly used when discussing a system of building components as opposed to a single material.

Past design paths

Single-pane window glass was commonly used well into the 20th century. The proliferation of skyscrapers, and the extreme amount of thermal transfer that occurred over their extensively glazed exteriors, prompted the commercial production of double-and triple-glazed insulating units in the 1940s and 50s. Thermal isolator gaskets were installed around metal parts (e.g. mullions and pressure plates) to insulate them and provide protection against air and moisture penetration.

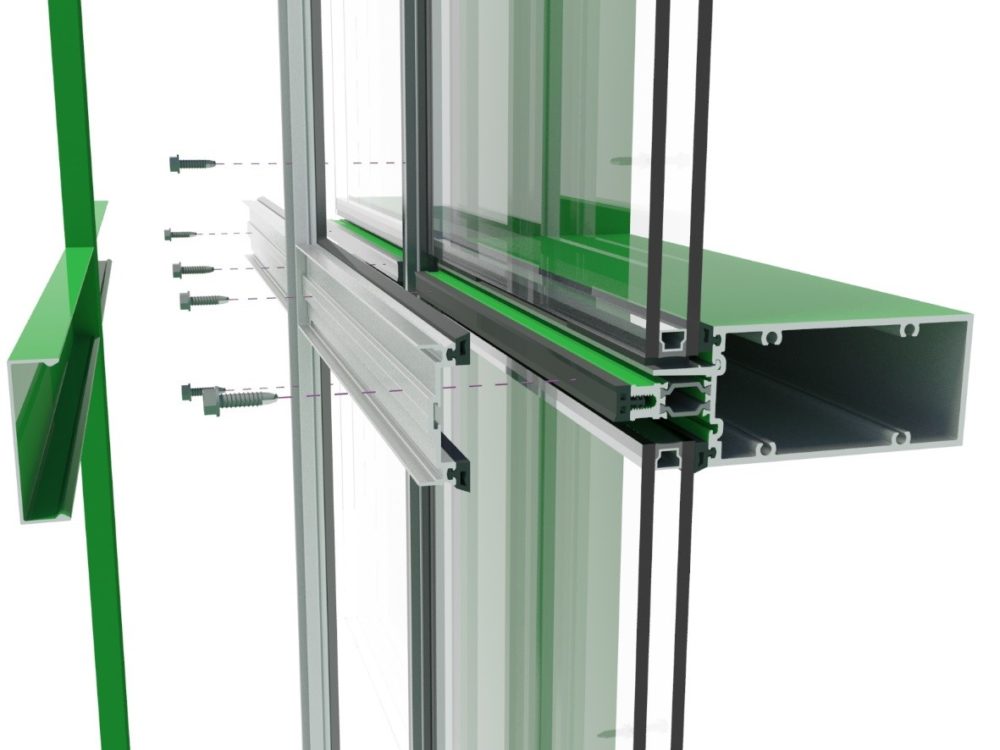

Photo © CR Laurence/US Aluminum. Photo courtesy Azon

In the 1980s, insulating glass—double panes with inert gas or a vacuum seal between them—enabled further reduction of heat transfer. Following that, low-emissivity (low-e) coatings for glass were developed. Together, low-e coatings and insulating glass units (IGUs) improved the thermal performance of glazed openings immensely, since the glass itself represents the largest surface area over which thermal transfer occurs.

The most significant thermal path, or bridge, remaining in glazed openings was that of the spacer. In its earliest and simplest configuration, the IGU consisted of two panes, or lites, separated by an aluminum or metal spacer. The spacer was sandwiched between seals that held it between the lites.

IGUs used in curtain walls were dual-sealed; polyisobutylene (PIB) primary sealants were applied directly to the glazing, while silicone was used secondarily and provided structural performance. Spacers were usually U-shaped; a desiccant was placed within the canal to absorb any moisture between the lites.

This construction provided structural strength. However, it also provided a conductive conduit of metal that allowed heat and/or cold into the building, as well as created a temperature differential between the center and the edge of the glass, leading to condensation. Replacing the traditional aluminum spacer with warm-edge spacers (constructed from low-conductivity materials such as polymers or low-conductivity stainless steel) was a first step toward improving framing. Warm-edge spacers are now typically an integral part of fenestration systems.

Even after the introduction of IGUs and warm-edge spacers, remaining paths for thermal transfer were significant, costing building owners countless dollars in climate control. Further, market demand and more rigorous standards for thermal performance continued to grow while curtain walls—with their previously unmatched expanses of glazing—became the dominant design element in contemporary skyscrapers.

Condensation and associated mold and moisture problems (especially in sensitive environments such as healthcare facilities) also became targets for improvement. These health-related factors combined to make the need for framing advancements imperative, and the area addressed next was manipulation of the aluminum profile itself.

Image courtesy Tubelite

Understanding the curtain wall

There are two main categories of curtain walls. The first comprises the ‘stick-built’ systems, in which all structural components are assembled at the project jobsite. Stick-built systems are optimal for building façades with little repetition among components, where architectural designs are more complex and few economies of scale can be reached by factory production.

Unitized curtain walls, on the other hand, involve having glazed and aluminum components factory-assembled into panels and shipped to the construction site. Good for tall structures that use repeat components, this method is advantageous in that the controlled factory setting improves tolerances and installation to complete the enclosure faster.

The extruded aluminum members comprising the curtain wall frame can be two separate pieces (one for the building interior and one for the exterior) joined at pressure points, as is common in stick-built systems. They can also be a single extruded profile, which is more common for unitized systems. With either method, engineered systems to interrupt the thermal bridge created by the metal cross section must be installed. Two systems include the pour-and-debridge thermal barrier and polyamide thermal barrier strips.

The pour-and-debridge thermal barrier

For this method of thermal barrier, the aluminum profile is extruded with a channel designed to hold an insulating polymer. The channel is mechanically abraded to ensure adhesion of the polymer. A mechanical lock inside the thermal cavity locks the thermal barrier to the aluminum to provide superior structural strength for the composite. (Structural strength is extrusion- and cavity-specific; there is a great deal of data available depending on the extrusion type.) This allows the maximum separation of the aluminum required for lower U-factors while providing structural strength.

Polyurethane polymers are poured as liquid into the thermal barrier channel (or cavity) where they solidify into a structural, thermal component. Finally, the metal bridge (or floor) is removed from the bottom of the aluminum channel during the debridging operation. The result is a true, non-metal-to-metal structural aluminum and polymer composite. By eliminating the conductive pathway of the interior to the exterior of the curtain wall framing, the energy efficiency of the building is significantly improved.

Polyurethane polymers feature thermal conductivity 1300 times lower than aluminum and the thermal benefits occur within a very small amount of separation. The width and type of thermal barrier separation should be determined based on the given building’s energy use or reduction requirements. (Once the thermal performance is determined [usually by U-factor], the manufacturer will select the appropriate thermal barrier and the required separation to achieve the desired performance.)

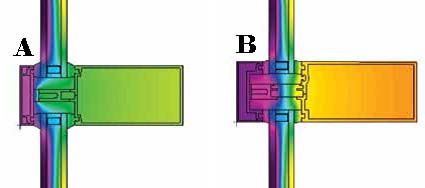

B: Curtain wall profile with polyurethane thermal barrier improves thermal efficiency by interrupting the flow of cold air through the extrusion. This also works to interrupt the flow of hot air in desert climates. Simulations conducted with – 18 C (0 F) outside and 21 C (70 F) inside temperatures.

Images courtesy Azon

A complete separation of the aluminum framing with an encapsulated polymer core maintains critical structural abilities to avoid strains and forces. Curtain walls —especially those used on tall buildings—are considered structural façade elements as part of a building’s wall system and must provide shear and tensile strength to sustain loads from high winds or even blasts or hurricanes. Thermal barriers must also accommodate stresses in the unitized curtain wall system that are created by thermal expansion and pressure differences. Fortunately, polyurethane polymers offer an exceptional amount of structural strength, particularly shear strength, allowing designers to maximize the span of glazing within the curtain wall framing. (Manufacturers of thermal barrier composites should be able to provide expected shear values, and structural testing, based on the type of extrusion selected.)

In addition to the introduction of a polymer to interrupt the thermal bridge, energy efficiencies can be gained by manipulating the shape of the aluminum extrusion itself. The latest developments in this area include wide cavity and dual cavity construction.

Wide cavity

Creating a wider cavity in the frame achieves a lower U-factor in most fenestration products. One can compare the U-factor of 2.44 W/m2K (0.43 Btu/[hr-F-ft]), achievable with a thermal isolator (Figure 1a) to that of a wider cavity, achieved by the use of a polyurethane thermal barrier (Figure 1b). In this example, the U-factor is improved to 2 W/m2K (0.35 Btu/[hr-F-ft]), and can be lowered to 1.7 W/m2K (0.3 Btu/[hr-F-ft]), assuming the use of performance glazing.

Dual thermal barrier

If one debridged cavity performs well, then two will perform even better in many instances. In dual thermal barrier systems, the U-factor can improve by as much as 20 percent, depending on cavity size and location, and fenestration type. Greater condensation resistance can also be achieved. Additionally, the dual cavity allows for wider span openings for greater glass area and, consequently, increased daylighting. Dual thermal barrier designs also allow for the use of triple-glazing for U-factors of <0.20.

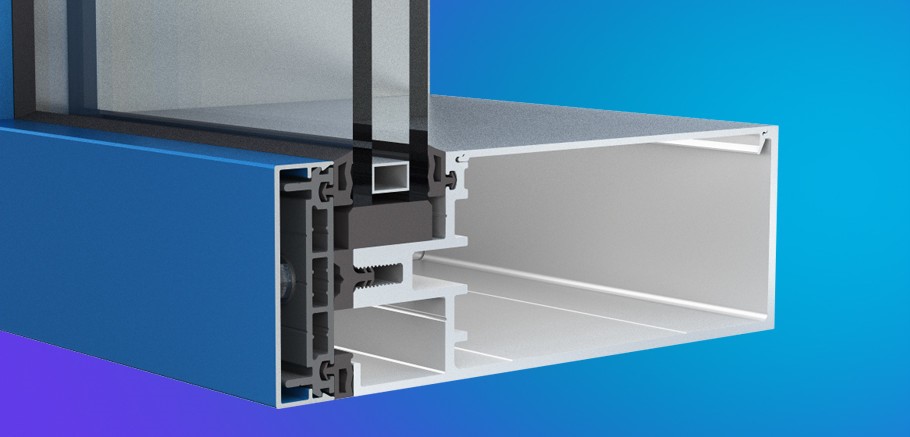

Polyamide thermal barrier strips

Polyamide barriers represent an alternative to the polyurethane-based pour-and-debridge method. They are pre-extruded, structural plastic insulating strips that usually have multidirectional glass fiber reinforcing to improve load transfer.

For wall systems utilizing polyamide strips, two separate aluminum extrusions are designed—one interior and one exterior—and channels in the aluminum profiles are created to hold the barrier strips. These channels must be knurled, or bent, to produce teeth that improve the shear strength of the assembly, as well as hold the polyamide strip and prevent shrinkage. (In many curtain wall applications, the shear strength of the composite is typically not critical because the composite I value comes from the interior tube. Shear values for composite assemblies using strips generally achieve between 800 and 2200 for 100-mm [4-in] section. Additionally, there is thermal cycling data in which there is minimal drop in shear after field exposure or thermal cycling.) Once the polyamide strip is inserted into the aluminum’s channel, the entire assembly is rolled, or crimped, to create the bond and turn the system into a composite.

Image courtesy YKK AP

Advantages of the polyamide thermal barrier strips include:

- greater thermal separation with the use

of less metal; - some of the greatest thermal separation widths available; and

- use of less metal, enabling conservation of resources.

The strips also have a similar coefficient of expansion and contraction to aluminum, ensuring the system’s overall stability.

Since the interior mullions are completely separated from the exterior ones in these unitized systems, a benefit of the method is they can be finished independently from one another. This gives designers the option of specifying high-performance coatings on a building’s exterior while choosing another, more suitable option for the interior, such as a coating that is highly mar-resistant or lower in cost.

Ongoing developments in curtain wall systems include alternative designs for pressure plates. Polyamide was used to develop a new pressure plate system that is up to 20 percent more efficient than earlier designs and has a 10 percent gain in condensation resistance factor. Pressure plates with polyamide have excellent thermal values and require no special handling or fabrication. They are installed similarly to aluminum pressure plates.

Conclusion

The curtain wall and glazing design and manufacturing industry has come a long way in reducing unwanted heat loss/gain from building interiors. The steady evolution of fenestration assemblies has ensured this advancement. An advantage is many of the improvements bring additional benefits, such as controlling condensation and creating more choices for coatings.

Ben Mitchell, CSI, is the extrusion coatings sales and marketing manager for AkzoNobel, a global paints and coatings company and producer of specialty chemicals. He has a bachelor’s degree in comprehensive science from Urbana University in Ohio. Mitchell started at AkzoNobel in 1990 as a lab chemist formulating (PVDF) coatings, and moved into product management. He can be reached at ben.mitchell@akzonobel.com[1].

Chad Ricker is the market team manager at Technoform Bautec NA. He has an engineering background, graduating from East Tennessee State University with a master of science in technology with a concentration in engineering. Ricker has been a part of Technoform’s team for more than a decade, beginning as an engineer and progressing to lead consultative marketing efforts. He can be contacted via e-mail at cricker@technoform.us[2].

Jerry Schwabauer is the Azon vice president of sales and marketing, a position he has held since 2000. Jerry is active in American Architectural Manufacturers Association (AAMA) and is a frequent speaker about the topic of optimizing thermal performance in commercial fenestration in North America and Asia. He can be contacted at jschwabauer@azonusa.com[3].

- ben.mitchell@akzonobel.com: mailto:ben.mitchell@akzonobel.com

- cricker@technoform.us: mailto:cricker@technoform.us

- jschwabauer@azonusa.com: mailto:jschwabauer@azonusa.com

Source URL: https://www.constructionspecifier.com/thermal-efficiency-in-glazed-curtain-wall-systems/