Think Zinc: Designing and specifying for longevity

by Katie Daniel | September 29, 2017 3:20 pm

[1]

[1]by Ben Kweton, CSI-EP

With natural roof and façade metal materials that have been in use for centuries, importance should be placed on specifying a material not solely for its longevity, but also with an understanding of its long-term aesthetic potential (and pitfalls). Just as we do not plant saplings without the idea of them one day growing into trees, zinc cannot be specified without an appreciation for the patina and aging process. The material is long-lasting, lends itself to unique detailing, and is amazingly versatile, but an understanding of the maturation process manages client expectations and allows a specification to leave a legacy long after the project is complete.

Architectural zinc has enjoyed a successful history of European application for almost three centuries and increasing popularity in North America since the early ’90s. As an alloy primarily comprising of zinc with additional controlled amounts of titanium and copper, the material provides a unique, low-maintenance aesthetic at an extremely low amortized lifetime cost.

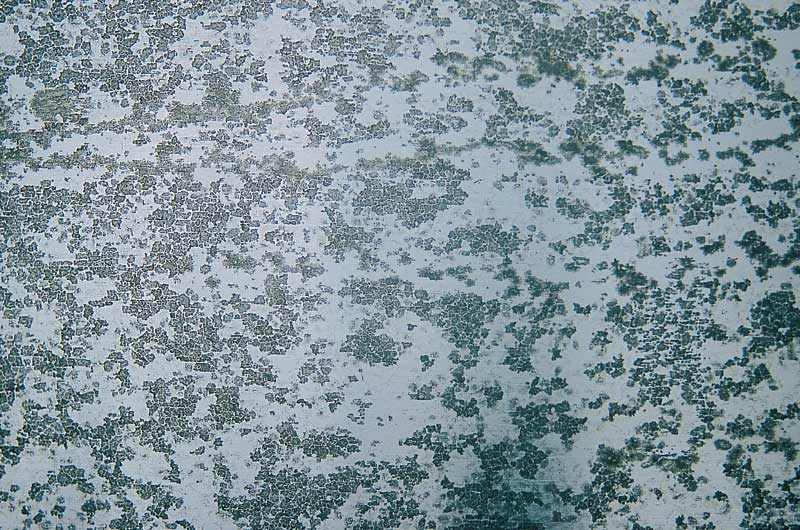

Freshly produced natural ‘bright-rolled’ zinc will have a shiny silver appearance and a smooth finish. Without any applied protective organic coatings, it will also be the surface condition that begins the patina process the fastest. Bright-rolled zinc is the material on which most other ‘weathered’ products are based. Without the head start of a secondary patination process, natural zinc can be expected to slowly weather to a matte-gray patina. The duration of this process depends on environmental and building conditions, with the greatest predictor of final appearance being the observation of local in-situ projects that have been through several years of exposure.

Common surface patina is achieved through the formation of first zinc hydroxide or Zn(OH)2, then zinc carbonate (ZnCO3). Both of these compounds not only add to the aesthetic appearance of the product, but also protect the material and increase its longevity.

In marine environments, zinc, combined with salt in the air, will form zinc oxychloride (Zn2OCl2) on the surface. In an age where most people lack the patience and foresight to enjoy the natural process of patination, there are several methods of producing zinc with a more aged appearance. The three main sources for these enhanced surface conditions are phosphating, pigmentation, and a natural pickling process.

The phosphating process deposits a phosphate-crystal coating onto the natural zinc alloy. The duration of the phosphate process and thickness of the coating determine the finished color range and luminance. Thus, this method produces a zinc coating rather than a head start on the natural patina process. Any scratching or scuffing will reveal the underlying alloy and start to weather naturally, potentially causing aesthetic concerns. Through the life of a phosphate product, the alloy is expected to eventually develop its natural patina compounds and force the phosphate coating to give way.

Tinted products can be produced in a multitude of colors and are typically applied over natural bright-rolled or phosphate zinc. The initial appearance usually preserves the initial random and natural texture of zinc and these coatings. Just as with the phosphate surface aspect, the pigments can be expected to fade and the natural patina of zinc to overtake the initial appearance. Exposure, slope, environment, and wetting and drying cycles all play a part in determining how long this process will take.

Lastly, a weathered look can be achieved through a pickling process, where the alloy is etched in an acid bath to achieve either a natural blue-gray or graphite-gray appearance. It is important to note in the case of pickling, the process is actually bringing out the natural patina formation, and two separate alloys are responsible for the different shades (blue-gray and graphite-gray).

After long-term weathering, the materials will remain lighter and darker by comparison. The initial appearance of these surfaces tends to have a subtle directional grain running lengthwise through the material, though this grain will dissipate as the patina develops. Should either of these surfaces be scuffed or scratched, the self-healing properties of the alloy will restore the surface through repatination, eventually matching the surrounding metal and becoming unnoticeable. The healing process is a distinct advantage over phosphate and tinted products that use a single alloy.

[2]

[2]Design considerations

While it is exciting to get the photography team and drone pilots out right after the landscaping is done and the ribbon cutting is happening, design/construction professionals also need to consider the potential life cycle of zinc can go well past a century on wall applications, and 80 to 100 years on a roofing application. Though it is difficult to extrapolate what the aesthetic will be into the next decade—much less the next century—some considerations should be taken past the initial display of material samples.

The very best predictor of long-term surface appearance is to physically observe a zinc project that has had the opportunity to weather. Most, if not all, zinc manufacturers keep a running list of projects based on type of project, specific material, and locale, and make this available to any interested parties. It is important to note how long a project has been in place and how the weathering process has changed the tone and texture of the surface in relation to initial samples, and equally critical to address any questions or concerns directly with the manufacturer, representative, supplier, or installer.

Exposure plays a very important role in the patination process. A slightly pitched roof weathers more quickly than a steeply pitched roof, which weathers more quickly than a façade. For this reason, tinted or pigmented zinc is typically not used on roofing applications. The only way to achieve a long-term appearance darker than the matte pewter gray patina is by using a separate alloy specifically designed to weather and maintain a darker appearance through its life cycle.

Consistent and uniform weathering can be a greater challenge in a façade application. Though the same factors apply, walls often receive less exposure to wetting and drying cycles from protective overhangs. Though patination of zinc in a façade application will take much longer to weather uniformly, it is reasonable to expect that it will happen eventually. The speed at which a project weathers into the natural patina is highly dependent on its microclimate.

Zinc manufacturers do their best to mitigate tonal variation from batch to batch. Tonal variation occurs naturally and may be found within the same coil or sheet. Since the material is not painted, it exhibits the natural colors of the constituent elements. This is part of the beauty of the product—it is not a cause for rejection.

Further, zinc can be expected to perform and last very well in marine environments. As mentioned previously, the patina is formed as a different compound, but zinc can also react with the salt air to form a water-soluble white zinc chloride crystal. This is not adhesive by nature and is typically washed off through rainfall or even an occasional washing to maintain the desired appearance. Again, even in a marine environment, there is a reasonable expectation of an 80- to 100-year life cycle with proper design and installation, depending on exposure.

| OIL-CANNING |

Oil-canning, or perceived waviness in the pan of the panels, is the skeleton in the closet for the architectural metal community. Even perfectly installed roofs and walls will exhibit this phenomenon to some degree, and poor installations only serve to exacerbate the situation. Unfortunately, there is no magic-bullet solution to the issue, though it is possible to put a little lipstick on the pig and help ameliorate the situation with the following suggestions.

Oil-canning is never a cause for material rejection, but should be explained and managed prior to fabrication and installation. The manufacturer, fabricator, and installer may all have valid suggestions on how to make the project look as good as possible. |

[3]

[3]Proper detailing

Zinc, like any other metal roof and façade skin, is best treated as a water-shedding or rainscreen system, working in conjunction with weather barriers to achieve highly functional, long-term solutions. Each zinc manufacturer can provide guidance as to proper detailing. Some key points include the following:

- zinc has a high coefficient of thermal expansion and should have accommodations included in the design, such as floating clips and notches for fasteners;

- a provision for backside drying and moisture escapement should always be implemented, and a ventilation mat should be used under every zinc roof assembly;

- panel clips should not only allow for thermal expansion, but also accommodate the increased depth due to the ventilation mat (typically 6.5 mm [¼ in.] taller than a standard clip);

- red rosin paper is not to be used under zinc, as it produces an acidic vapor detrimental to the product;

- all synthetic underlayment should be specified as ‘high temp;’ and

- any accessory flashing, cleat, or similar shall be zinc, galvanized, or stainless steel.

The first consideration at any joint should be how to achieve the detail without solder or sealant. Zinc is extremely malleable and durable and lends itself well to traditional details achieved through a high level of craftsmanship. Responsible zinc manufacturers should be willing to help a client achieve proper detailing for any aesthetic, as well as provide installation training to ensure the material is installed correctly, with proper care, and at a high skill level.

When the situation dictates the need for sealant or solder, one should keep in mind:

- sealing joints can potentially trap moisture behind the zinc panels, decreasing product life;

- when a caulk is necessary, a zinc-compatible, pH-neutral product should be used;

- for soldering, it is important to follow individual manufacturers’ surface preparation instructions and use a zinc-specific soldering flux;

- lead-free, 60/40, and 50/50 are all acceptable solder formulations; and

- it is best to use a soldering iron instead of a torch, taking care not to overheat the zinc, as soldering at a high heat can lead to potentially burning through the zinc material.

[4]

[4]Although there are many ways of properly fabricating and folding zinc, there are two major considerations that should be kept in mind on the fabrication and installation end. Once the material is properly installed, it can withstand brutal climate conditions, from arctic blasts to sub-Saharan heat, but care should be taken to install zinc at over 10 C (50 F), or provisions should be made to heat any material that will be worked in colder temperatures.

Regardless of how warm the material is at the time of fabrication, if zinc is fabricated in the same manner as a steel product, problems are likely to arise. Roll-forming and brake-forming zinc should be done with equipment designed with proper bending radii for zinc. The main consideration for this equipment will be softer bends done at a greater radius.

It is important to ensure any fabricator has a proven track record with zinc and can produce multiple project and customer references. One can also research the best fabricators by contacting the zinc manufacturers; typically, if a fabricator works well with one brand, he or she can fabricate any zinc with a high level of proficiency.

Zinc ages gracefully and provides a beautiful, long-lasting impression. With proper detailing, fabrication, installation, and understanding, a century of service is not out of the question.

| CLEANING AND MAINTENANCE |

| When zinc is selected as a long-term, timeless solution for roofs and façades, what can be done to ensure expectations are met? The first and most important suggestion is to follow each manufacturer’s cleaning and maintenance instructions, as they vary from product to product. Following these directives ensures nothing has been done to void any material warranties.

In general, one should keep to the following recommendations:

An abundance of caution should be encouraged prior to doing anything more than a light cleaning or rinse. As zinc is a natural product that forms its own patina, time and patience is typically the very best solution. |

Ben Kweton, CSI-EP, is vice president of Sheet Metal Supply Ltd., a RHEINZINK distributor and systems partner, located in Mundelein, Illinois. He has been with the company since its inception in 1991. Kweton graduated from University of Wisconsin-Madison, and is a member of CSI, Metal Construction Association (MCA), and the Chicago Roofing Contractors Association (CRCA). Kweton can be reached via e-mail at ben@sheetmetalsupplyltd.com[5].

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/09/WMS-Boathouse-3.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/09/Glidewell-Investments-Missoula-MT-1.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/09/VA-Hospital-Louisville-6-interior.jpg

- [Image]: https://www.constructionspecifier.com/wp-content/uploads/2017/09/Patina-Process-Under-Magnification.jpg

- ben@sheetmetalsupplyltd.com: mailto:ben@sheetmetalsupplyltd.com

Source URL: https://www.constructionspecifier.com/think-zinc-designing-specifying-longevity/