The North American market has numerous standards for testing the performance and durability of windows, curtain walls, and insulating glass, including:

- American Architectural Manufacturers Association (AAMA) 503, Voluntary Specification for Field Testing of Newly Installed Storefronts, Curtain Walls, and Sloped Glazing Systems;

- American Architectural Manufacturers Association/Window and Door Manufacturers Association/Canadian Standards Association (AAMA/WDMA/CSA) 101/I.S. 2/A440, North American Fenestration Standard/Specification for Windows, Doors, and Skylights (NAFS); and

- ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation.

Passing these tests gives fabricators confidence they are producing a durable glazing system, and specifiers trust the product they selected is the right choice for the project. Framing design and glazing material, along with the edge seal design and spacer selection, all play a significant role in the ultimate success of a building envelope, especially for curved or bent glazing.

Opportunities with spacers

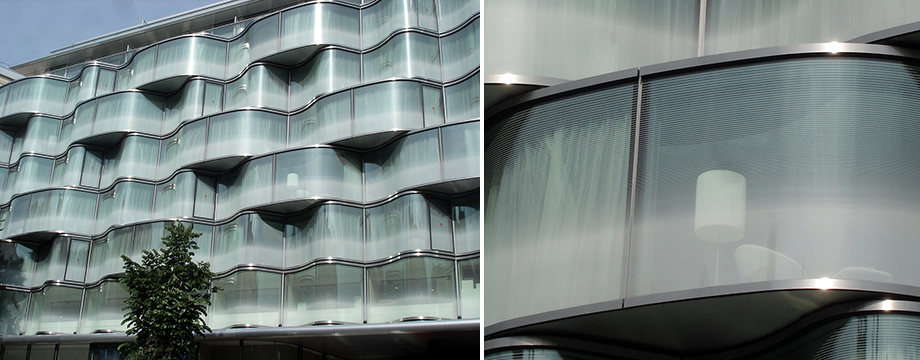

Flexible warm edge spacers are an ideal and cost-effective solution for both flat glass and bent glass applications, providing strength and long-term durability. However, when working with bent glass, flexibility is a key requirement in producing these complex units.

Gorman and his team are currently working on a building for Grace Farms in New Canaan, Connecticut—an independent, not-for-profit foundation supporting initiatives in the areas of faith, arts, social justice, and community. The project involves multiple all-glass buildings, where the owners did not want to see any vertical framing. Sciame worked closely with the design team, IG fabricator, and flexible spacer supplier to develop a glass frit and edge seal solution that creates an aesthetically pleasing sightline, showcasing the beauty of the glass through a softer color transition from the material to the spacer and edge seal.

Flexible silicone spacers offer reduced manufacturing steps and improved quality for commercial (bent and flat) insulating glass fabricators. In addition to manufacturing benefits, flexible spacers offer other performance enhancements over rigid spacer systems. They can:

- provide natural flexure during application to conform to the curves and bends of glass;

- offer a resilient, flexible construction that reduces edge seal stresses induced by glazing pressure, wind loads, and many other factors—reduced edge seal stress helps maximize insulating glass seal longevity;

- provide optimal thermal efficiencies;

- maintain durability and structural integrity in challenging bent and flat glass applications; and

- require less process steps and personnel to produce the insulating glass, minimizing the risk for error, rejects, or potential glass failures.

Ensuring a successful project

There are many ways building professionals can minimize risk and ensure long-term performance of

a building with bent insulating glass. The first, and possibly simplest, advice is also the most overlooked—involve the entire team as early in the design phase as possible to ensure there are no surprises concerning cost, design constraints, or aesthetics.

Another important factor is time and patience. As the glass is often one of the more costly parts of

a project, providing time for testing, mockups, and review is important.

“Try the design on a smaller scale mockup using the exact same components that were specified,” said Timm. “Show the building owner to ensure the design is what they want before going too far down the road. Then, once all the kinks are worked out on the small scale, move it to a bigger scale.”

Uniformity is a final component not only adding to the aesthetics, but also building performance. Consistency from the glass choice to the edge seal construction ensures the entire building envelope

is operating as a cohesive unit. Edge seals on bent insulating glass are typically subjected to even greater and more dynamic stresses than traditional flat glass, so fabricators and design professionals must be diligent about specifying and using the appropriate edge seal.

The complexities of manufacturing and using bent insulating glass cannot be completely eliminated, but with proper material selection, partners, and installation processes, these challenges can be minimized.