Throwing a curve into designs with bent insulating glass

by Katie Daniel | August 28, 2015 10:09 am

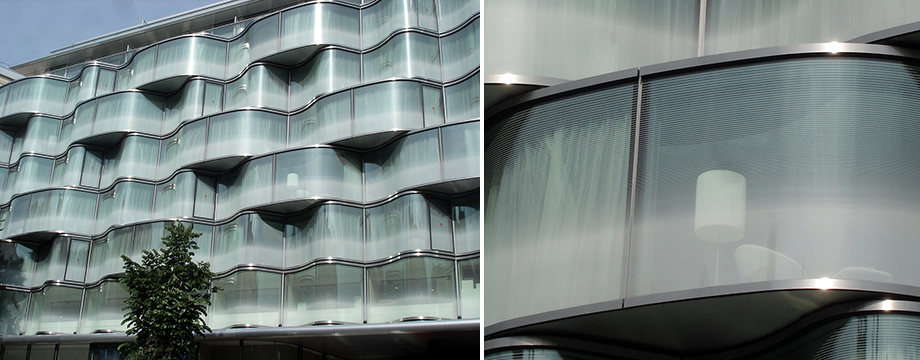

[1]

[1]By Joe Erb

Bent glass is a trend that has worked its way from sculptures and interior décor to becoming a major component of buildings’ exteriors. A modern, aesthetically pleasing design element, this glazing literally throws a curve into a façade, making people look twice and admire its unique structure. However, building professionals working with bent insulating glass (IG) must understand the process is as much a science as it is an art.

A structure made with large amounts of bent glass offers aesthetic benefits, but is also a perk for building occupants. Daylighting is proven to give inhabitants health benefits, including higher energy and comfort levels due to increased natural daylight. Today, thanks to advanced technology and improved products, it is possible to build a curved structure that is both efficient and comfortable for occupants.

A bent insulating glass project that has recently gained a lot of attention is Apple’s new headquarters in Cupertino, California. The structure is being built with all curved glass—not one piece of the building’s exterior is flat. Slated for completion next year and ringing in at nearly $5 billion, the project is an extreme example of a curved envelope and brings futuristic ideation to life.

However, is it realistic to bring this design element to buildings in an economical way that still makes it a mutually beneficial design for both the building owner and its occupants? The answer seems to be yes, but with a clause—the process must involve people with the same vision.

“Although it has been gaining popularity in the last five to 10 years, bent insulating glass is still such an unusual design element,” said Jay Gorman, senior project manager of Sciame, a New York City-based construction and development firm. “Architects and building owners want to offer something exciting that is still not seen everywhere. When it is used the right way, bent insulating glass can fulfill this need.”

Balancing aesthetics and economy

As an architect, specifier, and designer, properly balancing design and economic decisions can mean the difference between winning and losing a project. The requirements for improved thermal efficiencies and energy savings with building exteriors prove to be challenging, regardless of the glass type specified. However, bent insulating glass has additional challenges to consider, including stress, quality control during fabrication, and properly applying coatings.

So, how are irregularities minimized in a process lending itself toward inherent variation and potential flaws? Christoph Timm, an associate and façade specialist with Skidmore Owings & Merrill (SOM), says it starts with putting together the right team.

“Work with a fabricator you trust from past projects or one you know who has worked on structures you have seen and liked,” said Timm. “The earlier you can bring this team of experts together, the more economical and better off the end result will be.”

[2]

[2]The process and standards

Bent glass is inherently stronger than flat glass—in fact, the bending process to thermally curve a pane of glass creates the shell-like form that makes the unit more resistant to bending movement. Further, the thermal bending process adds stress to the glass; therefore, the climatic load (i.e. the pressure differences between the internal gas between glass panes and the external air) in curved insulating glass differs from its flat pane counterpart.

To thermally bend the glass, a sheet of flat glass is heated up in an oven to the point where it wants to slump, or bend. Once the glass is bent to its desired shape, it is quickly quenched of its heat through a burst of cold air. This process makes the bent glass stronger.

It is important to specify building components that help take on the stress put on the glass and minimize the risks of a breakage and failure. Understanding the entire window/glazing system and how it will be installed is also important to help ensure the performance of the bent insulating glass is not sacrificed.

Until recently, the process of making bent insulating glass was viewed as prohibitively expensive and brought about too many variables to be considered for large-scale projects. Now, manufacturing is becoming more streamlined and standardized, making it a more cost-effective solution that no longer throws projects completely out of scope. Further, bendable soft glass low-emissivity (low-e) glass options have been developed that help the building meet tightening energy codes.

[3]

[3]The North American market has numerous standards for testing the performance and durability of windows, curtain walls, and insulating glass, including:

- American Architectural Manufacturers Association (AAMA) 503, Voluntary Specification for Field Testing of Newly Installed Storefronts, Curtain Walls, and Sloped Glazing Systems;

- American Architectural Manufacturers Association/Window and Door Manufacturers Association/Canadian Standards Association (AAMA/WDMA/CSA) 101/I.S. 2/A440, North American Fenestration Standard/Specification for Windows, Doors, and Skylights (NAFS); and

- ASTM E2190, Standard Specification for Insulating Glass Unit Performance and Evaluation.

Passing these tests gives fabricators confidence they are producing a durable glazing system, and specifiers trust the product they selected is the right choice for the project. Framing design and glazing material, along with the edge seal design and spacer selection, all play a significant role in the ultimate success of a building envelope, especially for curved or bent glazing.

Opportunities with spacers

Flexible warm edge spacers are an ideal and cost-effective solution for both flat glass and bent glass applications, providing strength and long-term durability. However, when working with bent glass, flexibility is a key requirement in producing these complex units.

Gorman and his team are currently working on a building for Grace Farms in New Canaan, Connecticut—an independent, not-for-profit foundation supporting initiatives in the areas of faith, arts, social justice, and community. The project involves multiple all-glass buildings, where the owners did not want to see any vertical framing. Sciame worked closely with the design team, IG fabricator, and flexible spacer supplier to develop a glass frit and edge seal solution that creates an aesthetically pleasing sightline, showcasing the beauty of the glass through a softer color transition from the material to the spacer and edge seal.

Flexible silicone spacers offer reduced manufacturing steps and improved quality for commercial (bent and flat) insulating glass fabricators. In addition to manufacturing benefits, flexible spacers offer other performance enhancements over rigid spacer systems. They can:

- provide natural flexure during application to conform to the curves and bends of glass;

- offer a resilient, flexible construction that reduces edge seal stresses induced by glazing pressure, wind loads, and many other factors—reduced edge seal stress helps maximize insulating glass seal longevity;

- provide optimal thermal efficiencies;

- maintain durability and structural integrity in challenging bent and flat glass applications; and

- require less process steps and personnel to produce the insulating glass, minimizing the risk for error, rejects, or potential glass failures.

[4]

[4]Ensuring a successful project

There are many ways building professionals can minimize risk and ensure long-term performance of

a building with bent insulating glass. The first, and possibly simplest, advice is also the most overlooked—involve the entire team as early in the design phase as possible to ensure there are no surprises concerning cost, design constraints, or aesthetics.

Another important factor is time and patience. As the glass is often one of the more costly parts of

a project, providing time for testing, mockups, and review is important.

“Try the design on a smaller scale mockup using the exact same components that were specified,” said Timm. “Show the building owner to ensure the design is what they want before going too far down the road. Then, once all the kinks are worked out on the small scale, move it to a bigger scale.”

Uniformity is a final component not only adding to the aesthetics, but also building performance. Consistency from the glass choice to the edge seal construction ensures the entire building envelope

is operating as a cohesive unit. Edge seals on bent insulating glass are typically subjected to even greater and more dynamic stresses than traditional flat glass, so fabricators and design professionals must be diligent about specifying and using the appropriate edge seal.

The complexities of manufacturing and using bent insulating glass cannot be completely eliminated, but with proper material selection, partners, and installation processes, these challenges can be minimized.

[5]

[5]Conclusion

Building professionals now have the flexibility to get creative with building designs and achieve a façade that is beautiful and energy-efficient when correctly installed. The improvement of automated equipment and glass-bending technologies helps minimize hurdles, and the use of flexible warm edge technology for both flat and bent insulating glass continues to expand the possibilities for design professionals. New technologies and streamlined processes make a technically sound building designed for happy and productive occupants achievable. It is a trend bringing an interesting twist into the building and construction industry today.

Joe Erb has more than 20 years of experience in the fenestration industry. His current role as commercial sales specialist for Quanex Building Products includes driving awareness and use of high-performance glazing and framing solutions in the commercial market through education and technical support. Erb has degrees in mechanical engineering technology and industrial engineering technology from Kent State University in Kent, Ohio. He can be contacted by e-mail at joe.erb@quanex.com[6].

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/renaissance_paris_wagram_hotel-980x734-801_ded66-for-plotter.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/renaissance_paris_wagram_hotel-980x734-904_025eb-hi-res.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/Sick-Kids-oct2013.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/bent-glass-edit1.jpg

- [Image]: http://www.constructionspecifier.com/wp-content/uploads/2015/08/BAE-Systems-copy.jpg

- joe.erb@quanex.com: mailto:joe.erb@quanex.com

Source URL: https://www.constructionspecifier.com/throwing-a-curve-into-designs-with-bent-insulating-glass/